Sludge bin

A silo and sludge technology, applied to containers, packaging, underwater structures, etc., can solve the problems of dirty environment, water leakage, falls, etc., improve the installation environment, improve safety, and avoid blocking pollution mud effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

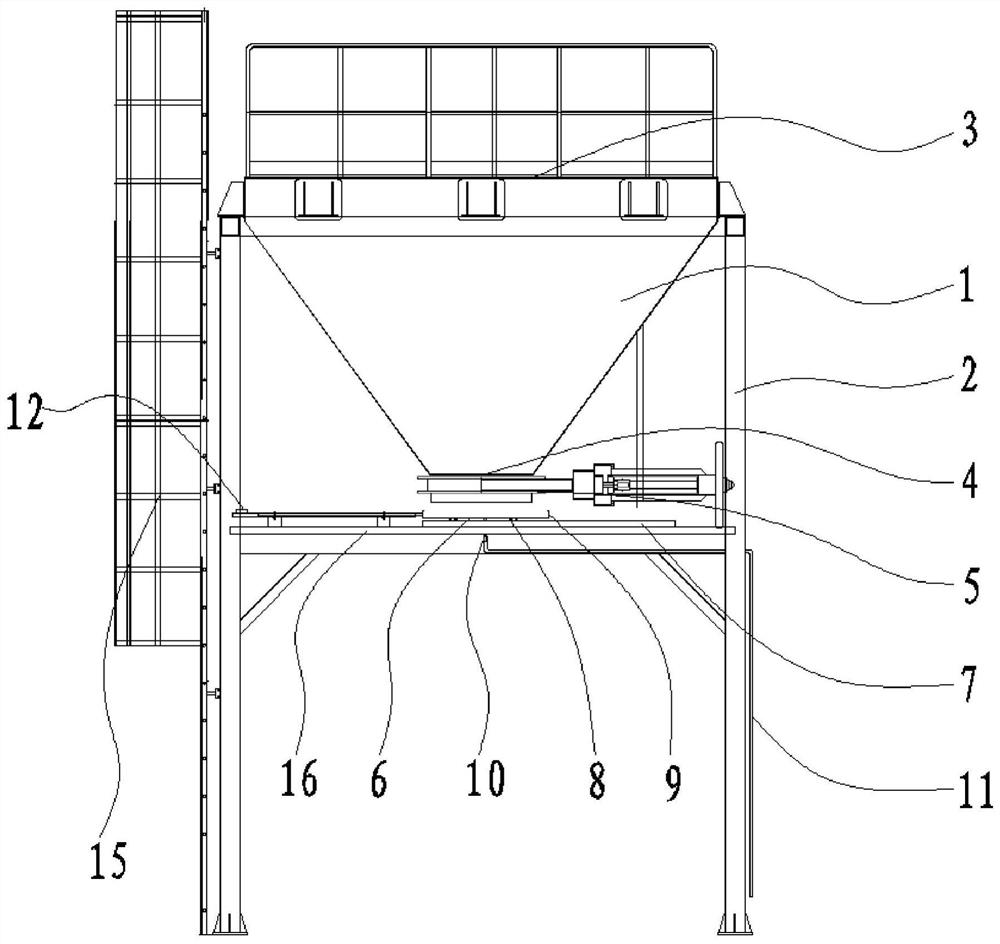

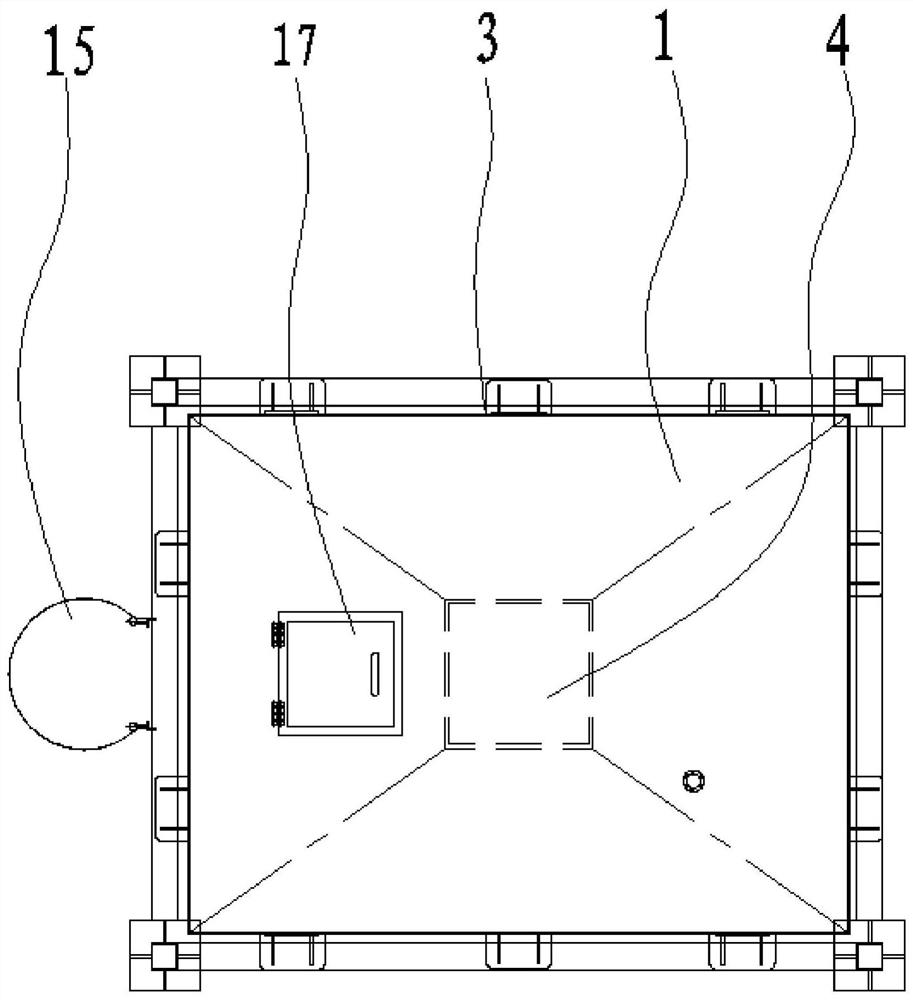

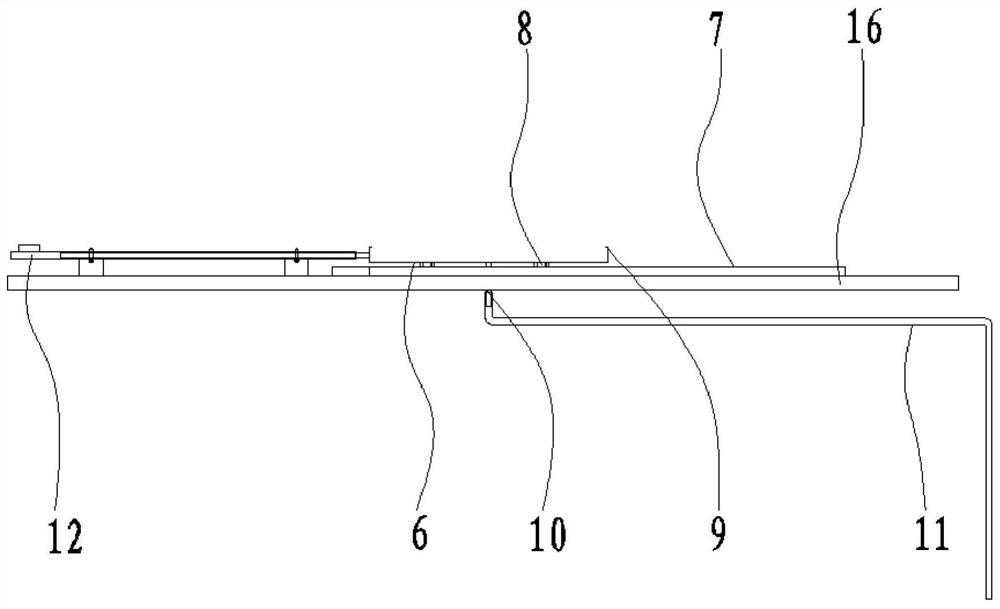

[0034] Such as Figure 1 to Figure 3 As shown, this embodiment includes a silo body 1 and a support frame 2 for supporting the silo body 1. In this embodiment, the silo body 1 is funnel-shaped, and the silo body 1 is set on the upper part of the support frame 2, the upper part of the silo body 1 is provided with a material inlet 3, the bottom of the silo body 1 is provided with a discharge port 4, and the discharge port 4 is provided with Discharge valve 5, the bottom of the discharge port 4 is provided with a water collection mechanism for collecting the leakage water of the discharge valve 5, and the water collection mechanism is connected to the leakage water collected by the water collection mechanism. The water is discharged from the drainage mechanism of the water collection mechanism, and the support frame 2 is provided with a device for driving the water collection mechanism to move to the vertical bottom of the discharge valve 5 and to leave the vertical bottom of the...

Embodiment 2

[0040] This embodiment includes a silo body 1 and a support frame 2 for supporting the silo body 1. In this embodiment, the silo body 1 is funnel-shaped, and the silo body 1 is located at The upper part of the support frame 2, the upper part of the silo body 1 is provided with a feed port 3, the bottom of the silo body 1 is provided with a discharge port 4, and the discharge port 4 is provided with a discharge valve 5. A water collection mechanism for collecting the leakage water of the discharge valve 5 is provided below the discharge port 4, and the water collection mechanism is connected to discharge the leakage water collected by the water collection mechanism into the The drainage mechanism of the water collection mechanism, the support frame 2 is provided with a driving mechanism for driving the water collection mechanism to move to the vertical bottom of the discharge valve 5 and to break away from the vertical bottom of the discharge valve 5 It should be noted that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com