Loading system

A technology of conveying system and supporting system, applied in the direction of hoisting device, transportation and packaging, loading/unloading, etc., can solve the problems of uncontrollable direction, material interference, damage to the outer packaging of materials, etc., to reduce mutual extrusion, The effect of avoiding breakage and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

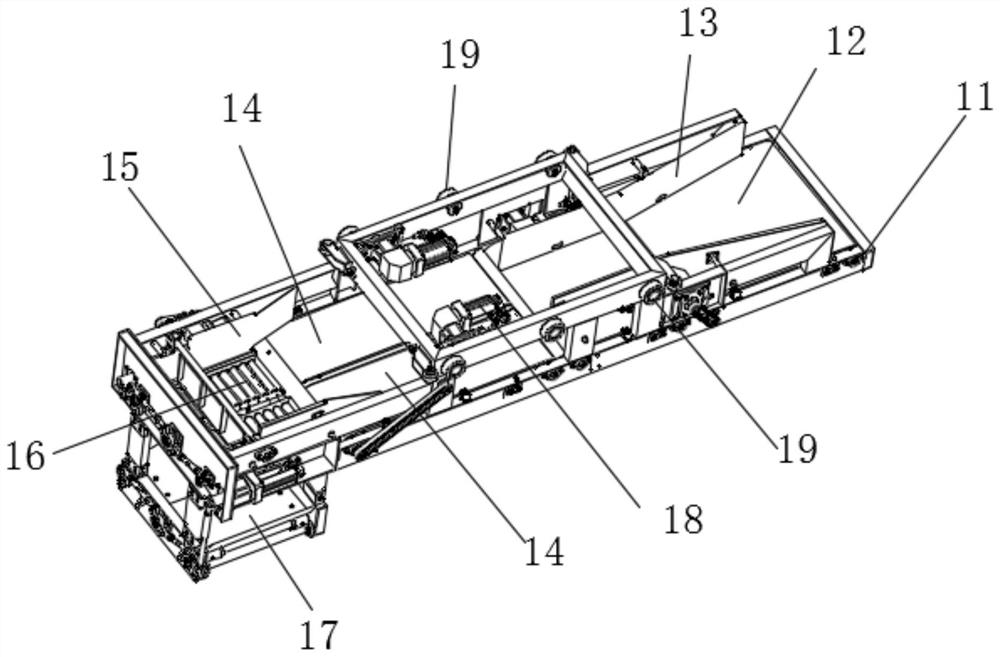

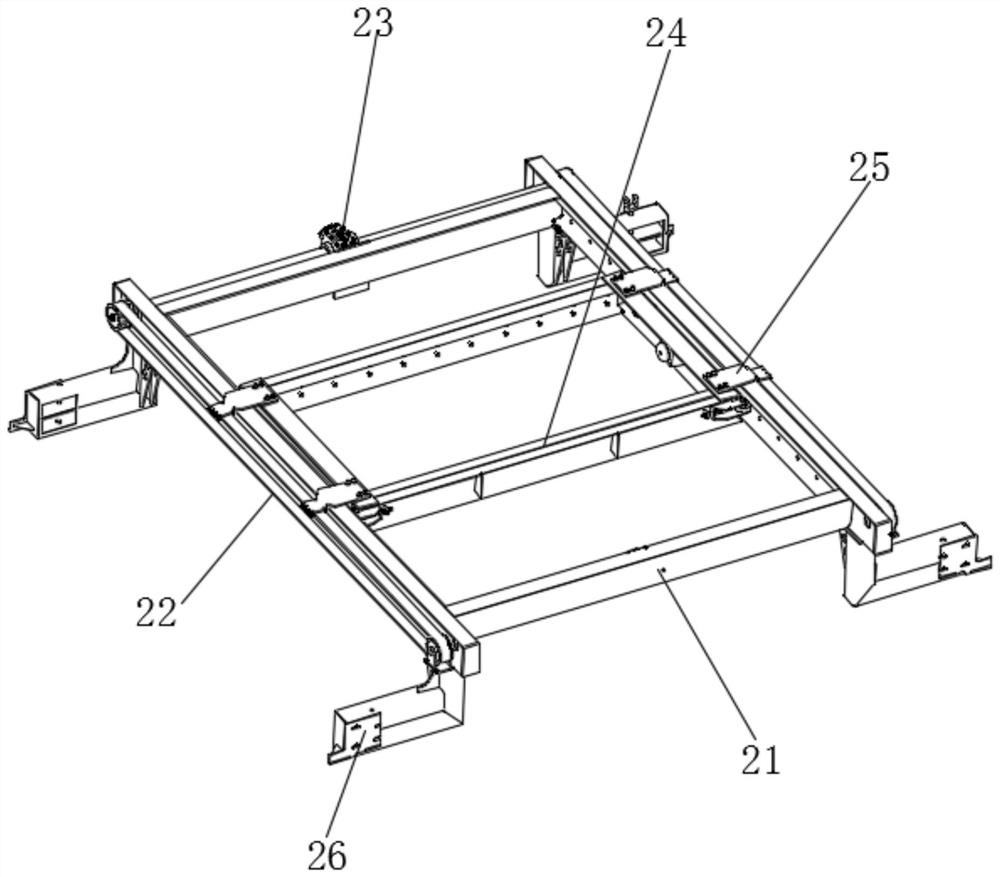

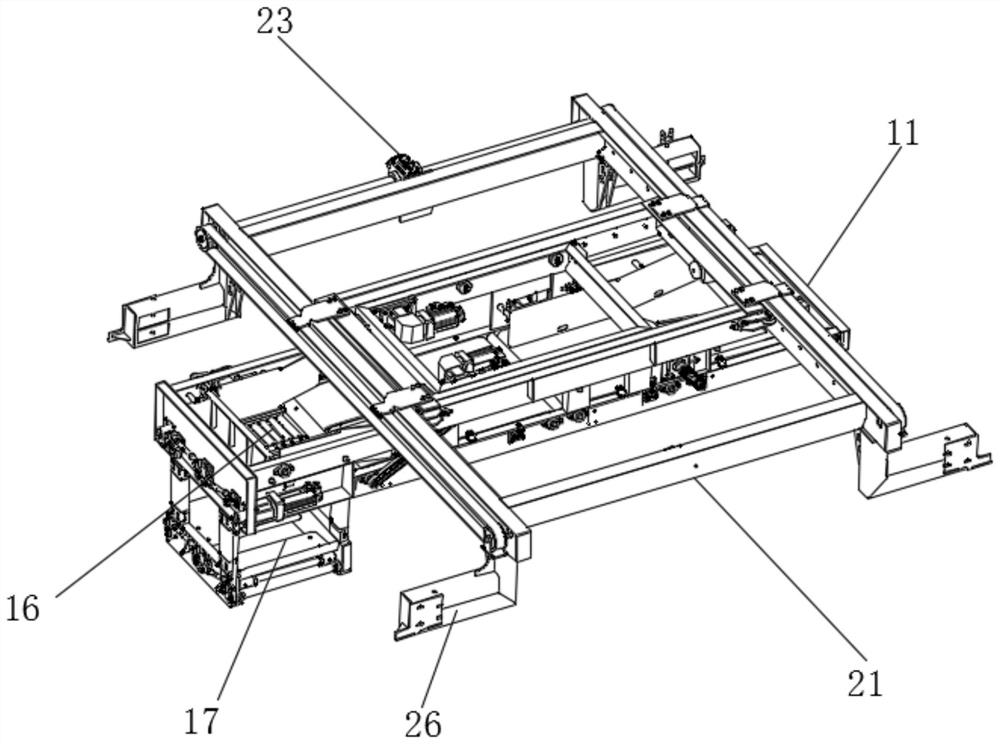

[0026] In this embodiment, a vehicle loading system includes a conveying system, a stacking system 1 and a support system 2 for supporting the conveying system and the stacking system 1, and the stacking system 1 is provided with an adjustment mechanism for adjusting the direction of materials.

[0027] In this embodiment, the conveying system is used to continuously transport the materials into the stacking system 1, and the adjustment mechanism in the stacking system 1 is used to adjust the direction of the materials so that the same batch of materials enters the vehicle in the same direction, so as to achieve The function of making materials neatly stacked. The adjusted materials fall directly from the stacking system 1 into the vehicle below the support system 2. The straight-line distance from the stacking system 1 to the vehicle is short. Setting the adjustment mechanism in the stacking system 1 can shorten the adjustment path and simplify the adjustment structure. , whi...

Embodiment 2

[0029] Such as figure 1 As shown, on the basis of the above embodiments, in this embodiment, the stacking system 1 includes an adjustment bracket 11, and the adjustment mechanism includes two adjustable Adjusting the conveyor belt 14 at a high speed, the two adjusting conveyor belts 14 are parallel to each other and the two ends are aligned with each other, and the moving direction of the regulating conveyor belt 14 is parallel to the moving direction of the material.

[0030] After the material enters the stacking system 1 through the conveying system, it enters the area where the adjustment conveyor belt 14 is located. There are two parallel adjustment conveyor belts 14 to drive the material to move forward. By controlling the differential speed of the two adjustment conveyor belts 14, the adjustment conveyor belt 14 can be adjusted. The material on the roller rotates to change the angle of the material, so as to play the role of adjustment. This solution can adjust the ang...

Embodiment 3

[0033] Such as figure 1 As shown, on the basis of the above embodiments, in this embodiment, the stacking system 1 further includes a guiding mechanism arranged on the adjusting bracket 11 and located at the entrance of the adjusting conveyor belt 14, and the described guiding mechanism includes a guiding mechanism The straightening conveyor belt 12 and the guiding baffles 13 arranged on both sides of the guiding conveyor belt 12 , the distance between the two guiding baffles 13 gradually decreases along the moving direction of the guiding conveyor belt 12 .

[0034] The material enters the conveying system in the way of placing vertical bags. When the conveying system conveys the material to the adjusting bracket 11, the material first enters the top of the guiding conveyor belt 12, and the guiding conveyor belt 12 drives the material to continue to move forward. Using the guiding baffle 13 The restriction on the material can make the material be fine-tuned before entering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com