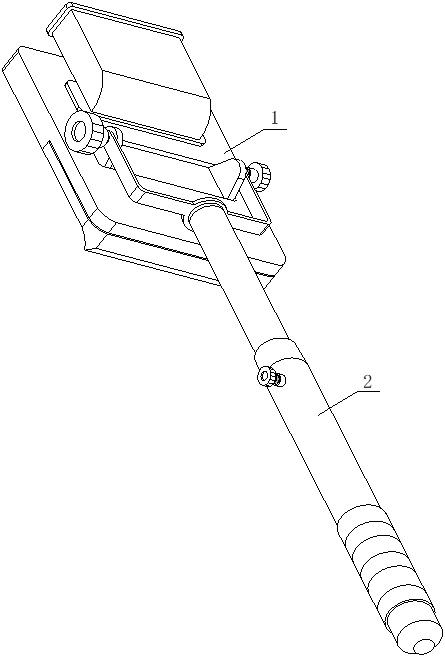

An integrated scraper for applying and smoothing wall putty and its operation method

An integrated, putty technology, applied in the direction of construction, building construction, etc., can solve problems such as low work efficiency, increased procedures, and unsafety, and achieve the effects of improving work efficiency, reducing procedures, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

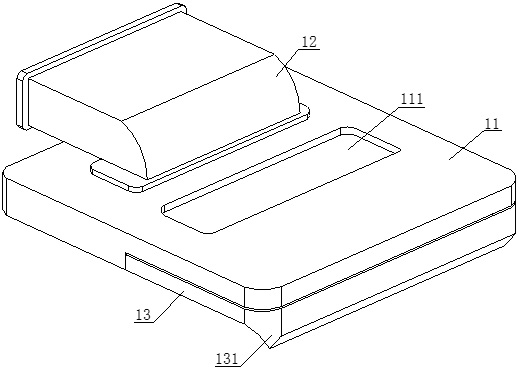

[0040] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, an operation method for applying and smoothing an integrated scraper with wall putty, comprising the following steps:

[0041] S01: Unscrew and lock the internal thread pipe head 233, adjust the angle between the U-shaped connecting frame bar 22 and the thickened fixed plate body 11, then tighten the loose lock internal thread pipe head 233, and adjust the length of the telescopic rod 21 make adjustments;

[0042] S02: Put the putty into the putty storage hopper 12;

[0043] S03: lift the blanking and smoothing mechanism 1 through the telescopic rod 21, and attach the thickened fixed plate body 11 to the wall;

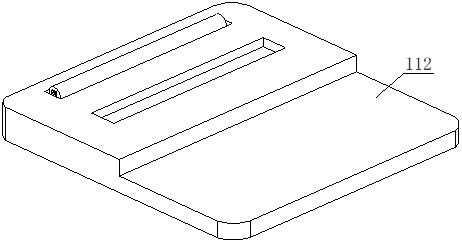

[0044] S04: The roller shaft 142 presses the connecting rod 141 into the installation groove 103, and the discharge baffle 145 that blocks the putty discharge port 101 in a vertical state tilts in the baffle moving cavity 102, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com