Novel phase-change material filling device for electric heat storage building radiant floor heating

A phase change material and filling device technology, applied in electric heating systems, heating methods, heating systems, etc., can solve the problems of affecting filling efficiency, residual accumulation, affecting the service life of device transportation, etc., to improve filling efficiency, avoid accumulation, The effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

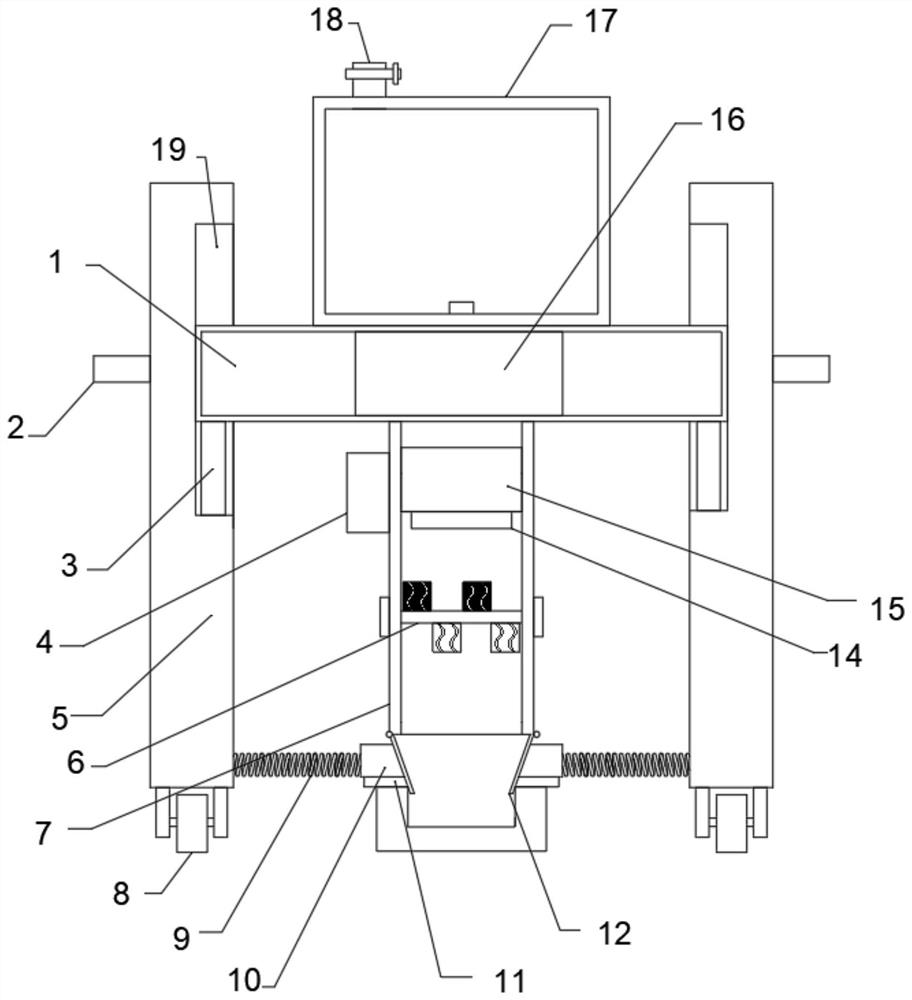

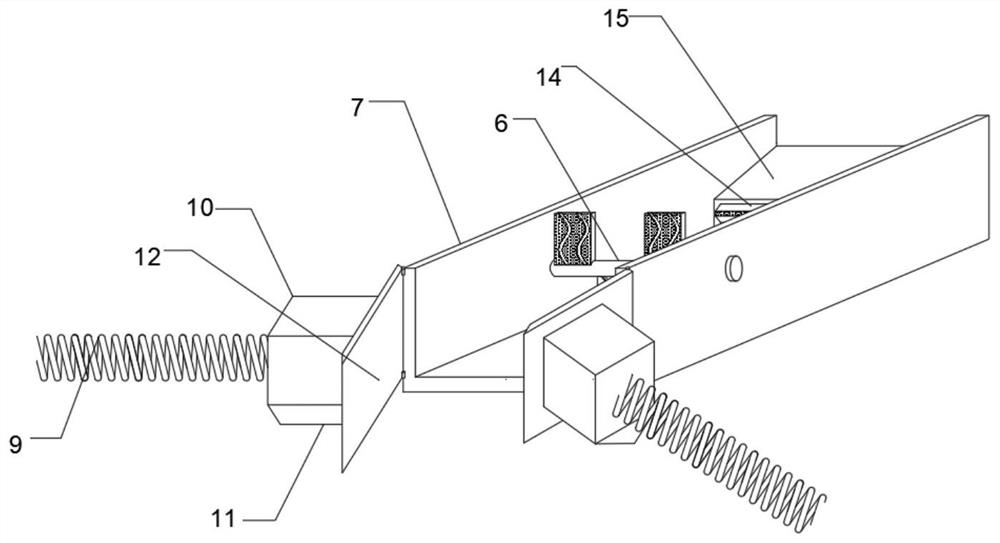

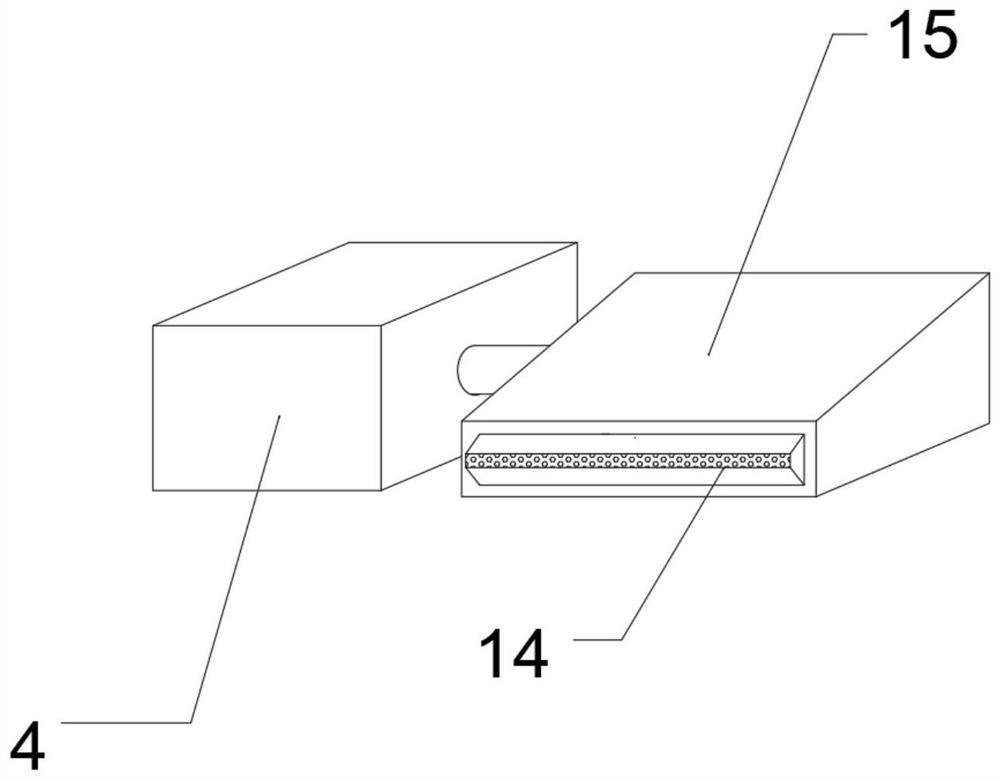

[0027] refer to Figure 1-4 , a new type of phase change material filling device for electric heat storage building floor heating, comprising a box body 1, a feeding mechanism is arranged on the top of the box body 1, a delivery pipeline 7 is fixedly connected to the outer wall of the bottom of the box body 1, and the outer wall of one end of the delivery pipeline 7 is fixedly connected There is an air pump 4, and the inner wall of the conveying pipeline 7 is fixedly connected with an air guide box 15, and the air guide box 15 is fixedly connected with the air pump 4. The air outlet pipe 14, the bottom of the air outlet pipe 14 is provided with a rotating mechanism, the rotating mechanism includes a first stopper 21 and a second stopper 22, the bottom of the air outlet pipe 14 is provided with a first rotating shaft 13, the first rotating shaft 13 and the conveying The pipeline 7 is connected in rotation, the top outer wall of the first rotating shaft 13 is fixedly connected w...

Embodiment 2

[0034] refer to Figure 2-6 , a new type of phase change material filling device for electric heat storage building floor heating, the outer wall of one end of the collecting box 17 is fixedly connected with a motor 25, the inner wall of the collecting box 17 is rotatably connected with a second rotating shaft 24, the second rotating shaft 24 and the motor 25 Fixedly connected, the outer wall of the second rotating shaft 24 is fixedly connected with a plurality of connecting rods 26, the other end of the connecting rod 26 is fixedly connected with a rotating plate 27, the rotating plate 27 is set to an S shape, and the outer wall of the rotating plate 27 is provided with a large amount of leakage holes.

[0035] During use, by setting the motor 25 to rotate the second rotating shaft 24, thereby driving the rotating plate 27 connected by the connecting rod 26 on the outer wall of the second rotating shaft 24 to rotate, the purpose of stirring the material inside the collecting b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap