Temperature control and condensation prevention system for high-voltage electrical cabinet

A high-voltage electrical and anti-condensation technology, which is applied in air-conditioning systems, household heating, space heating and ventilation details, etc., can solve the problems of reducing moisture content, condensation, and the inability to control the temperature of cable trenches, etc. Dew, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

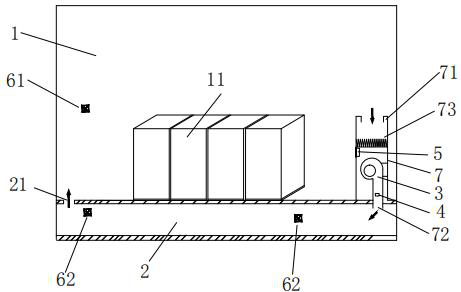

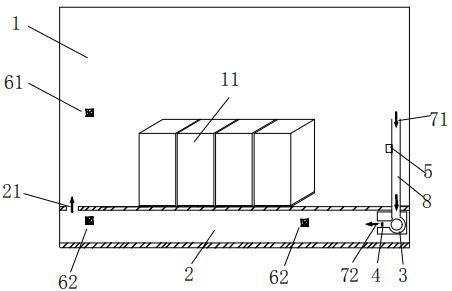

[0018] figure 2 It is the second embodiment diagram of the present invention;

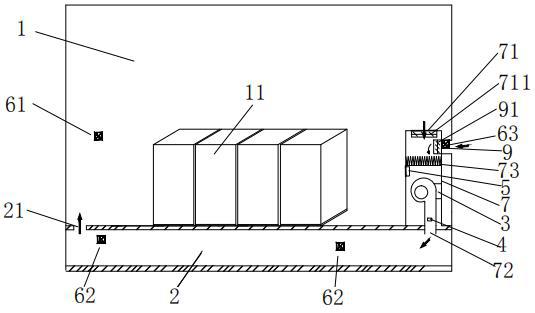

[0019] image 3 is the third embodiment diagram of the present invention;

[0020] The illustration marks are explained as follows: 1. Electrical room; 11. Electrical cabinet; 2. Cable trench; 21. Vent; 3. Fan; 4. Heating device; 5. Intelligent control system; 61. Temperature and humidity sensor in electrical room; 62. Cable trench temperature and humidity sensor; 63. Outdoor temperature and humidity sensor; 7. Cabinet; 71. Air inlet; 711. Air inlet valve; 72. Air outlet; 73. Filter device; 8. Air duct; 9. Air inlet ; 91, induced air valve. Detailed ways

specific Embodiment approach

[0021] In order to describe the technical content of the present invention more clearly, the following combines Figure 1 to Figure 3 for further description.

[0022] figure 1 It is an embodiment of the present invention, a high-voltage electrical cabinet temperature control and anti-condensation system, installed in an air-conditioned electrical room 1, the electrical room 1 has a cable trench 2, and the fan is located in the overall In the airtight box 7, the box 7 is placed in the electrical room 1, the intelligent control system 5 is located in the box 7, an air inlet 71 is opened above the box 7, and a connecting cable ditch 2 is opened below the box 7 The air outlet 72 of the box body 7 has a display screen connected to the intelligent control system 5 on the surface. Under this structure, the box body 7 itself constitutes the air duct 8 connecting the electrical room 1 and the cable trench 2, the air inlet side of the fan 3 is equipped with a filtering device 73, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com