Automatic feeding device for livestock breeding

An automatic feeding and livestock technology, applied in the field of livestock breeding, can solve the problems of unfavorable addition and supplementation of other nutrients, lack of scientific and advanced management technology, etc., to avoid manual addition, avoid untimely filling, and improve automation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

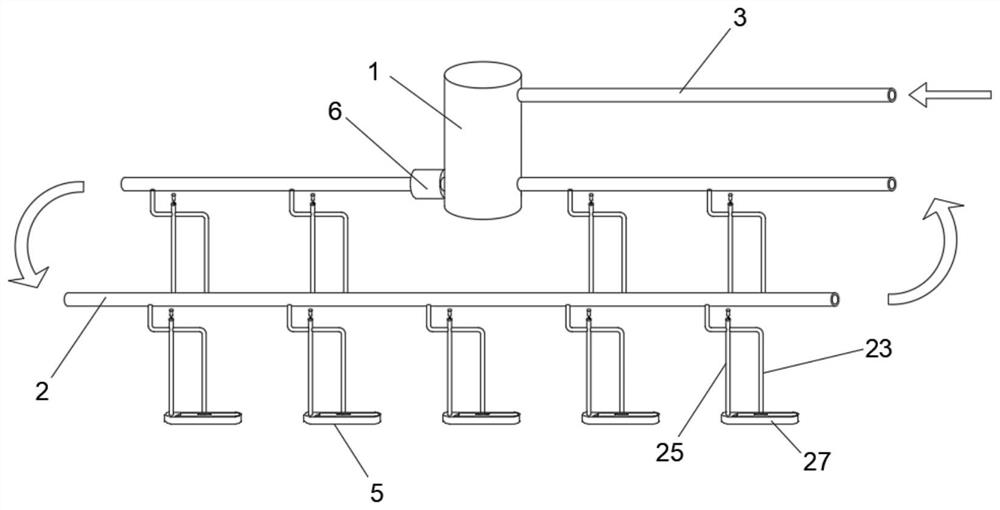

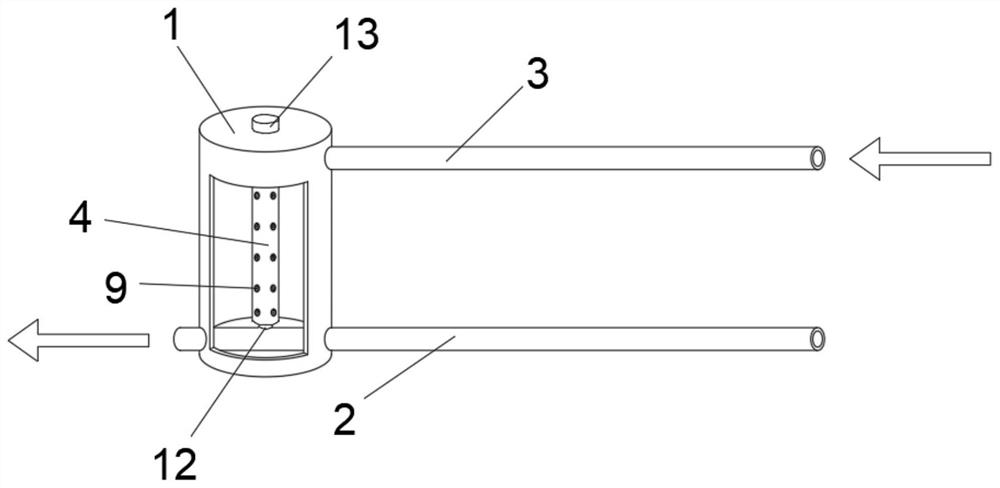

[0032] Such as Figure 1-7 As shown, an automatic feeding equipment for livestock breeding, including a water injection cylinder 1 and a diversion tube 2, the water injection cylinder 1 is provided with a cavity and is a closed cylinder, the diversion tube 2 is a closed loop, and the diversion tube 2 and the The water injection cylinder 1 is fixedly connected and arranged in communication. One end of the water injection cylinder 1 is fixedly connected with a water inlet pipe 3 on the side wall, and one end of the water inlet pipe 3 is connected to an external water supply device. A water filtering mechanism 4 is arranged in the water injection cylinder 1 .

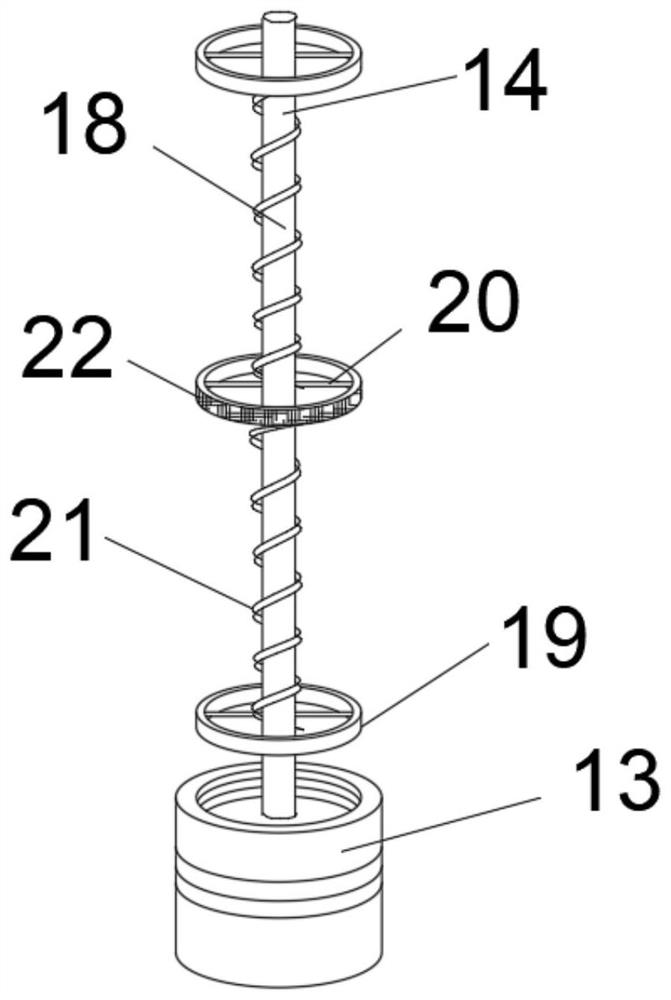

[0033] One end of the water filter mechanism 4 is fixedly connected with the guide pipe 2, and the other end of the water filter mechanism 4 penetrates the top surface of the water injection cylinder 1 and extends to the outside thereof. The water filter mechanism 4 includes a filter cartridge arranged in the water injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com