Ultrasonic atomizer

A technology of ultrasonic atomizer and ultrasonic atomizing sheet, which is applied in the direction of injection device, liquid injection device, fluid using vibration, etc. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

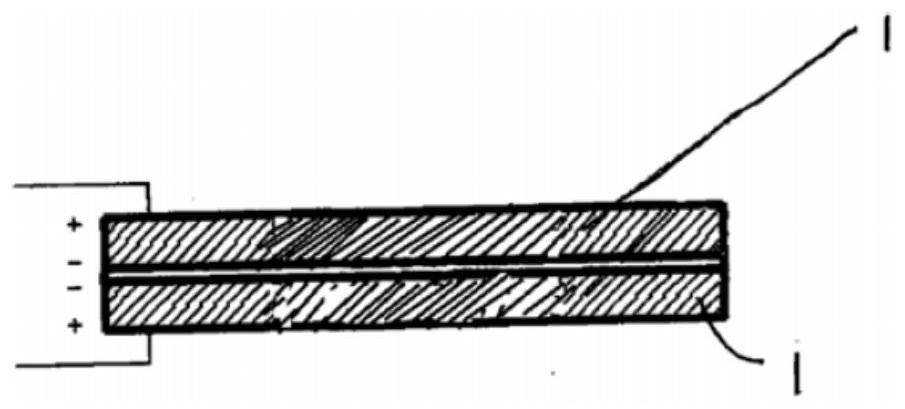

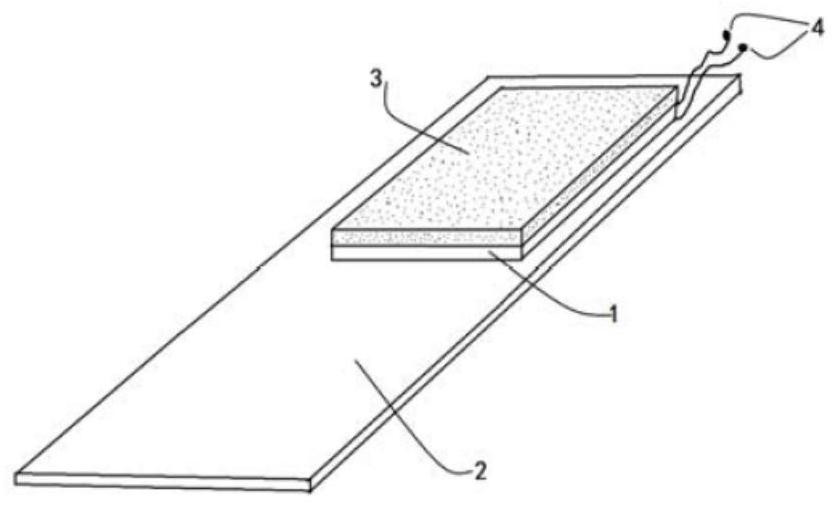

Method used

Image

Examples

specific example

[0080] Other specific examples are: single-component systems such as BaTiO3, PbTiO3, KxWO3, PbNb2O6, etc.; two-component systems such as PbTiO3-PbZrO3, PbTiO3-Pb(Mg1 / 3Nb2 / 3)O3, etc.; and three-component systems such as PbTiO3-PbZrO3 -Pb(Mg1 / 3Nb2 / 3)O3, PbTiO3-PbZrO3-Pb(Col / 3Nb2 / 3)O3, K1-x-zNaxLizNO3 (such as {LiX(K1-YNaY)1-X)(Nb1-Z-WTaZSbW) O3 etc.) etc. For specific examples of composite oxides and compounds that can be used in the present invention, see CN1206700A. Derivatives of the substances shown in Table 1 obtained by partially replacing Pb with any of Ba, Sr, Ca, etc., or partially replacing Ti with Sn, Hf, etc., can also be used.

[0081] The aforementioned piezoelectric ceramic plate material can also be mixed with a polymer material to form a piezoelectric sheet. Examples of the above-mentioned polymer materials are fluoroplastics (such as polyvinylidene fluoride, polytetrafluoroethylene), polylactic acid, and silica gel.

[0082] The piezoelectric ceramic preferably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com