Mechanical feeding device

A technology for mechanical and installation columns, which is applied in the field of mechanical loading devices, and can solve problems such as delays in parcel transportation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

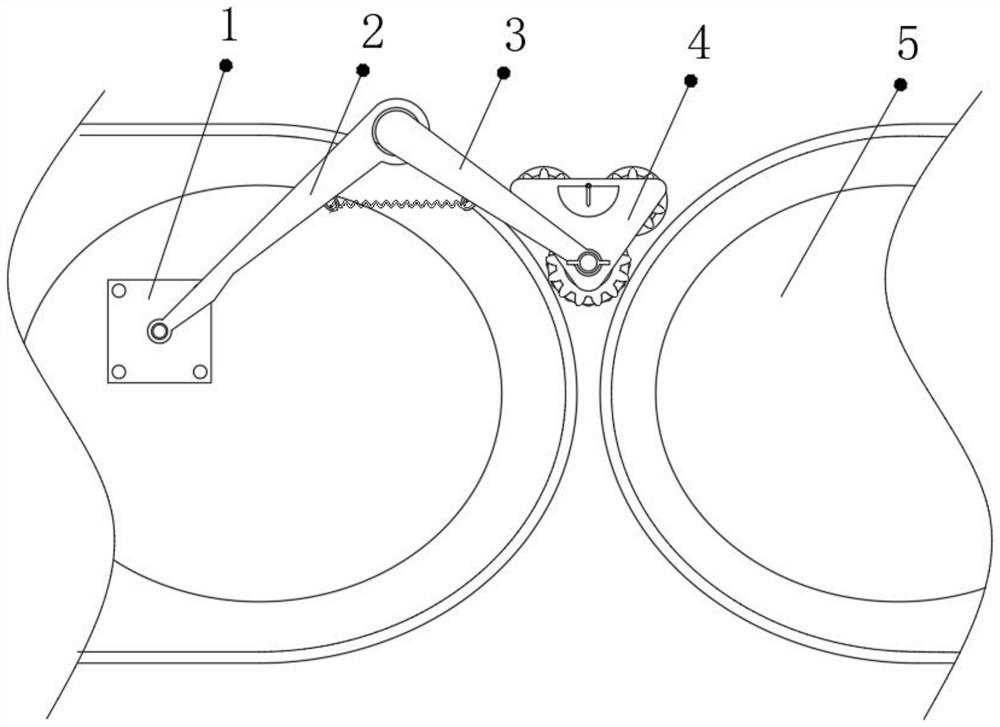

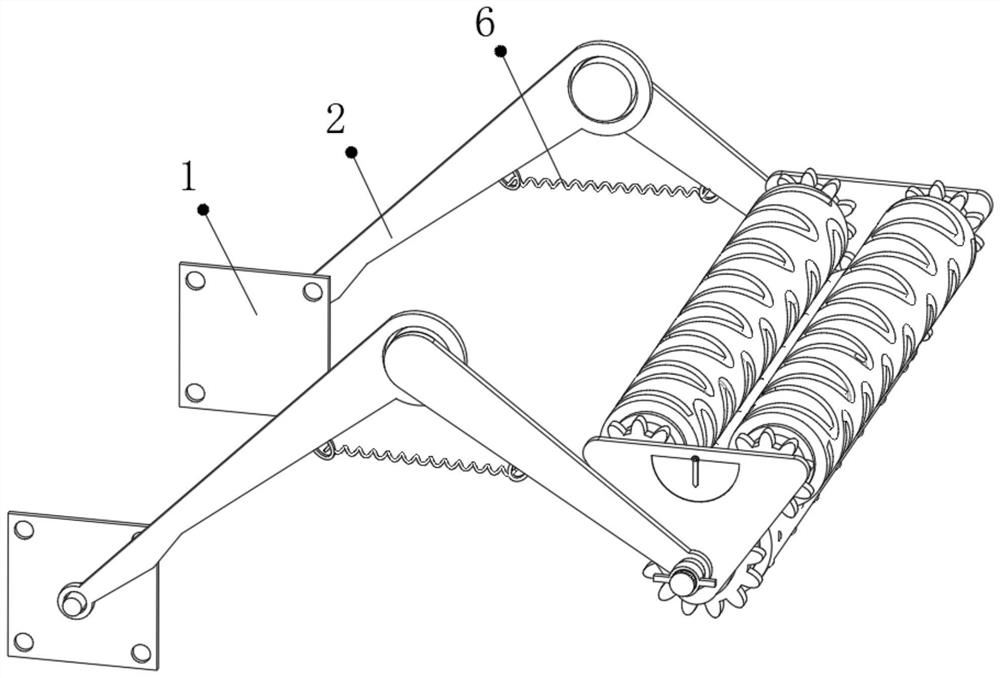

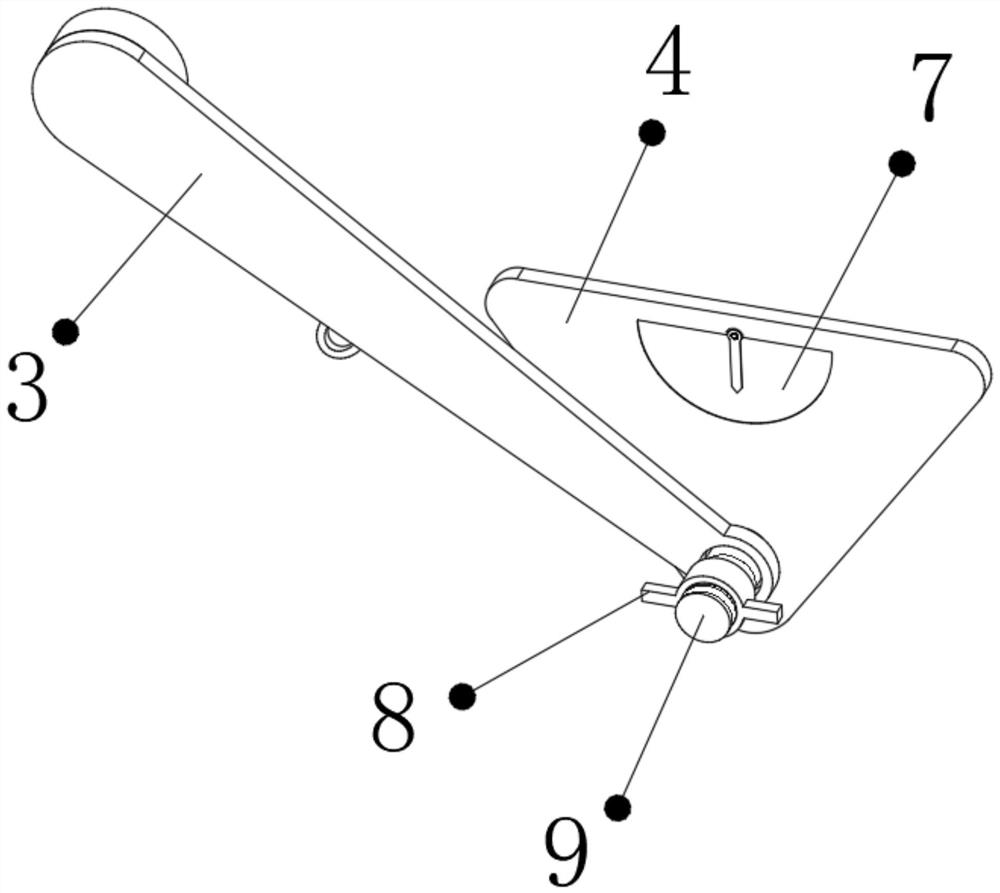

[0033] refer to Figure 1-6 , a mechanical feeding device, comprising a balance plate 4, a transmission mechanism is arranged on one side of the balance plate 4, and the transmission mechanism outer wall is connected with a transmission disc 13, and the outer wall of the transmission disc 13 is welded with a plurality of limit columns 14, The outer wall of the transmission plate 13 is clamped with the connecting plate 11, and the outer wall of the connecting plate 11 is provided with a plurality of limit holes 12, and the limit holes 12 are adapted to the limit posts 14, and the outer walls of one side of the connecting plate 11 are respectively welded. There are a fixed frame 18 and a transmission roller shaft 22, the outer wall of the fixed frame 18 is welded with a conveying roller shaft 17, and the conveying roller shaft 17 is set in a tubular shape, and the outer wall of the conveying roller shaft 17 is provided with a plurality of slag discharge holes 16, and the conveyin...

Embodiment 2

[0037] refer to Figure 7 , a mechanical feeding device. Compared with Embodiment 1, the outer wall of the balance plate 4 is connected with a waste residue box 25 by bolts, and the inner wall of the waste residue box 25 is connected with a cleaning plate by bolts, and the outer wall of the cleaning plate is provided with There is a hair brush 26, and the hair brush 26 is in contact with the drive roller shaft 22.

[0038]Working principle: When in use, the device is installed on the conveyor 5, and due to the elastic force of the tension spring 6, the driving roller shaft 22 will be pressed tightly on the conveyor belt of the conveyor 5, and the balance is adjusted with the assistance of the vertical measuring instrument 7 plate 4, so that its center of gravity is vertically downward, so as to ensure the balance of the device during operation. The volume of the device is small, and the height of the upper surface of the conveying roller shaft 17 is lower than that of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com