Cell preserving fluid filling production line

A technology for preserving liquids and production lines, applied in liquid bottling, packaging, bottling machines, etc., can solve problems such as increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

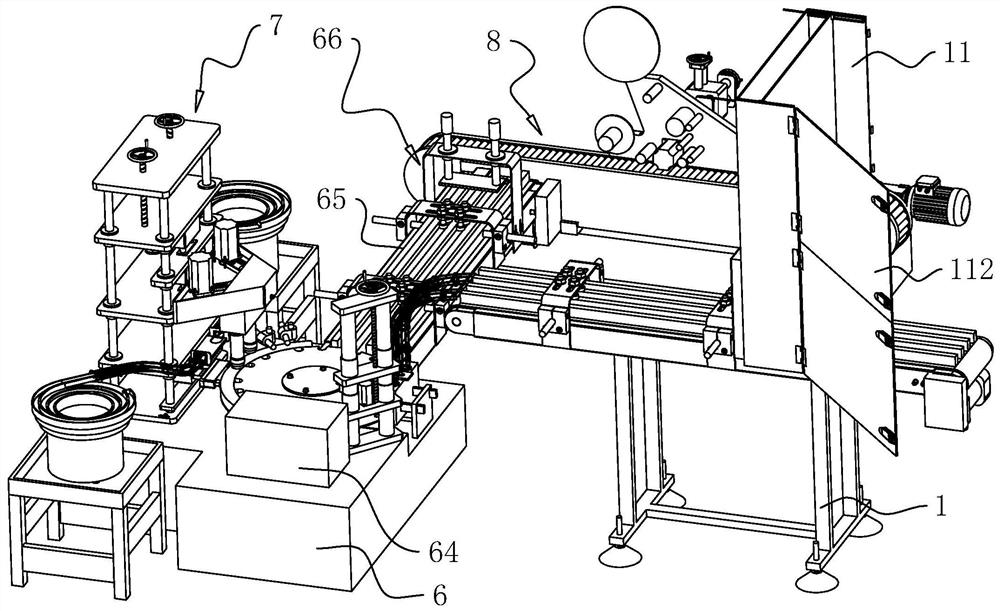

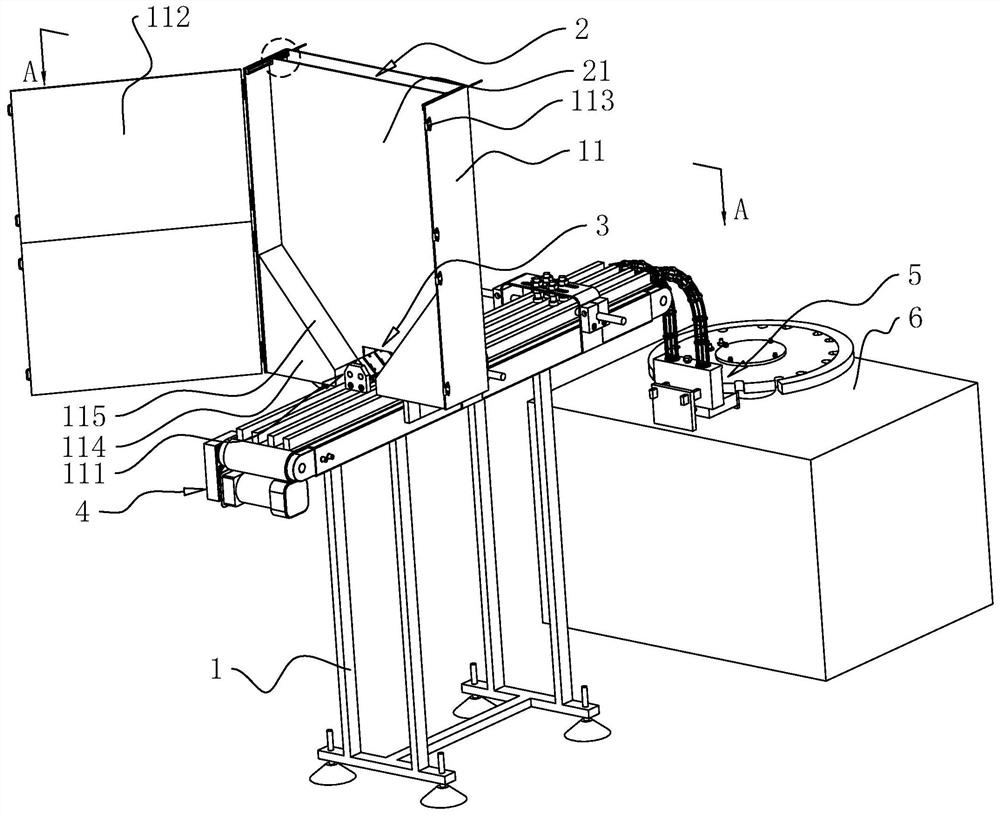

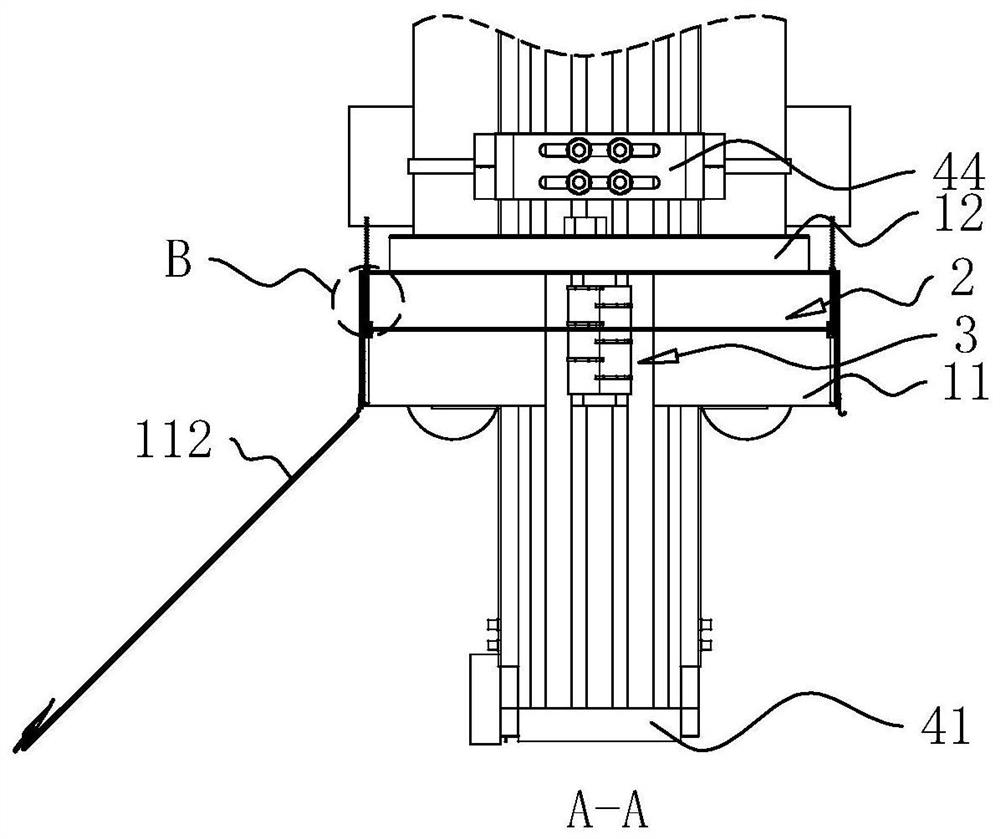

[0053] refer to figure 1 , the cell preservation solution filling production line includes a loading rack 1 arranged outside the filling rack 6, a capping device 7 arranged on the filling rack 6 and used for capping the bottle body, and a capping device 7 arranged outside the filling rack 6 And the labeling device 8 that is used to label the bottle, the top wall of the filling rack 6 is fixedly connected with a filling machine 64, the capping device 7 is arranged opposite to the feeding rack 1, and the filling machine 64 is located in the capping device. 7 and the loading rack 1, the filling machine 64 is set opposite to the labeling device 8, the side of the filling rack 6 close to the labeling device 8 is provided with a labeling conveyor belt 65, and the labeling conveyor belt 65 is provided with a The clamping part 66 for clamping the bottle body, the clamping part 66 can be a manipulator, and can also be a suction cup driven by an air cylinder.

[0054] refer to figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com