Steel structure housing assembly connection assembly

A technology for connecting components and steel structures, which is applied in the direction of building construction and construction, and can solve problems such as unstable connection of steel pipes and easy shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

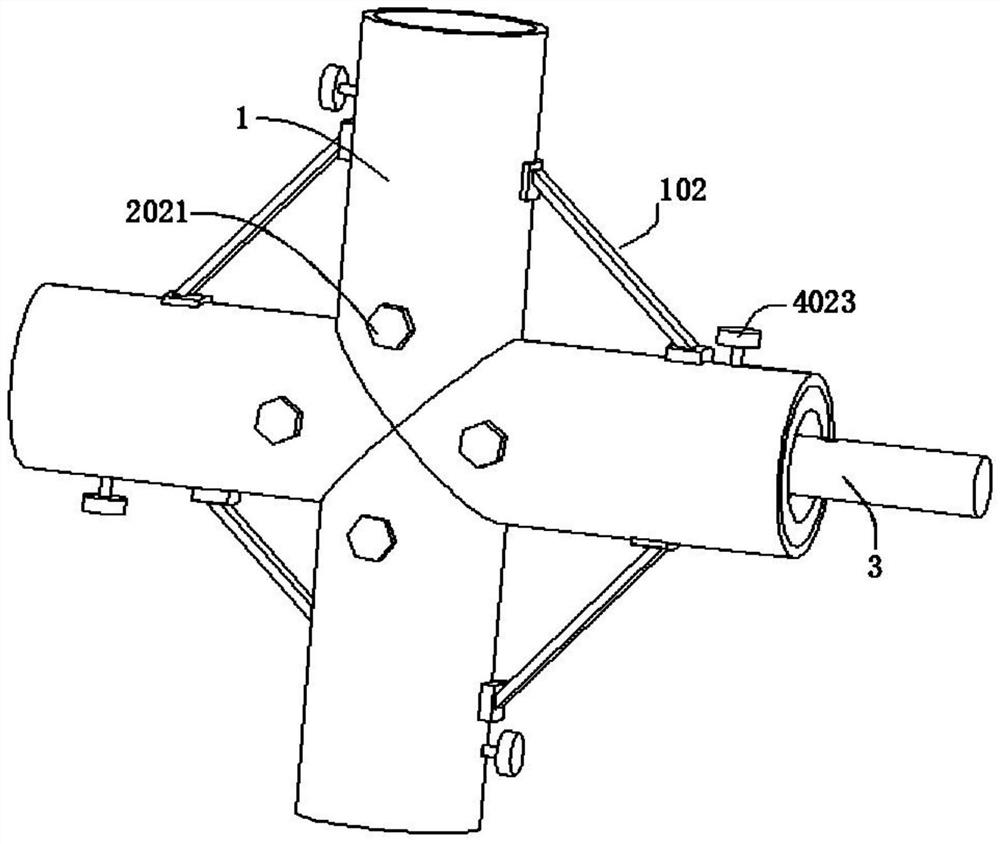

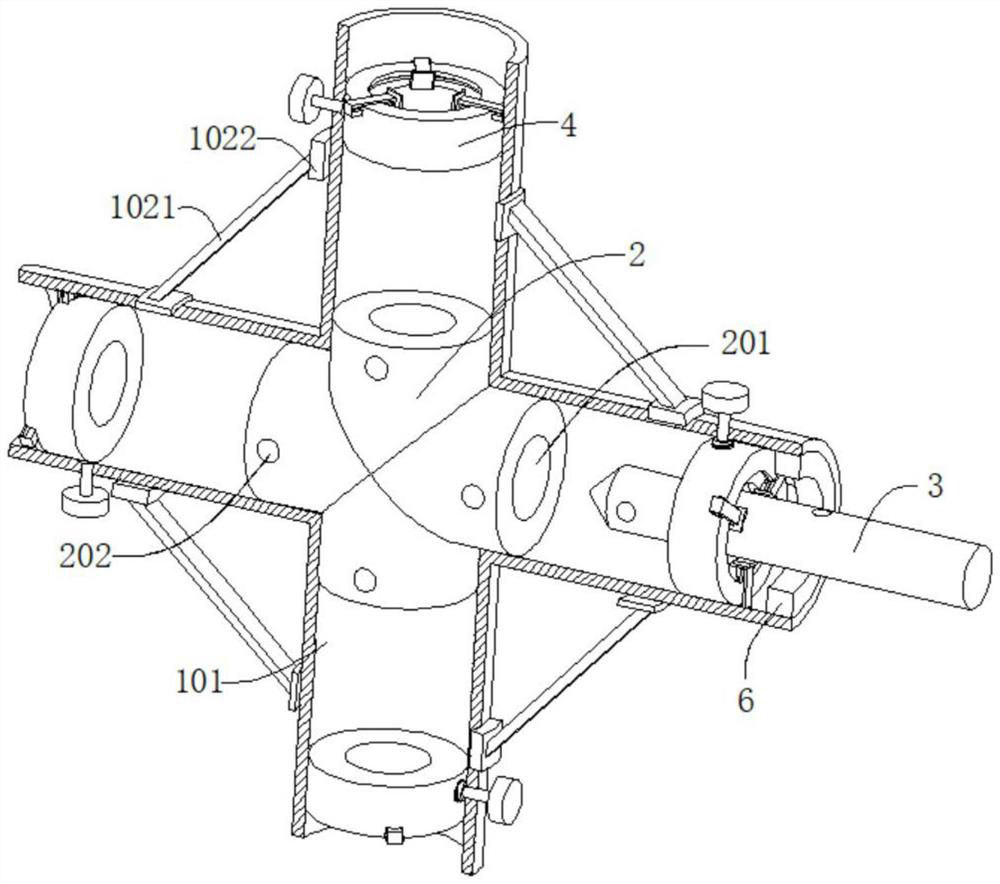

[0036] refer to Figure 1-2 , an assembled connection assembly for a steel structure house, comprising a connecting shell 1, the inner wall of the connecting shell 1 is connected with a steel pipe 3, the inner wall of the connecting shell 1 is connected with a cross column 2, the outer wall of the cross column 2 is dug with a blind hole 201, and the steel pipe 3 slides Connected in the blind hole 201, the connecting shell 1 and the cross column 2 are drilled with the outer wall of the steel pipe 3 to have a first threaded hole 202 that matches, and the inner wall of the first threaded hole 202 is movably connected with the first bolt 2021, connecting the inner wall of the shell 1 Also connected to the fixed disk 4, the fixed disk 4 is slidably connected with a moving block 404, and the outer wall of the moving block 404 is connected with an arc-shaped plate 4042, and the arc-shaped plate 4042 is movable against the steel pipe 3.

[0037] During construction, first insert the s...

Embodiment 2

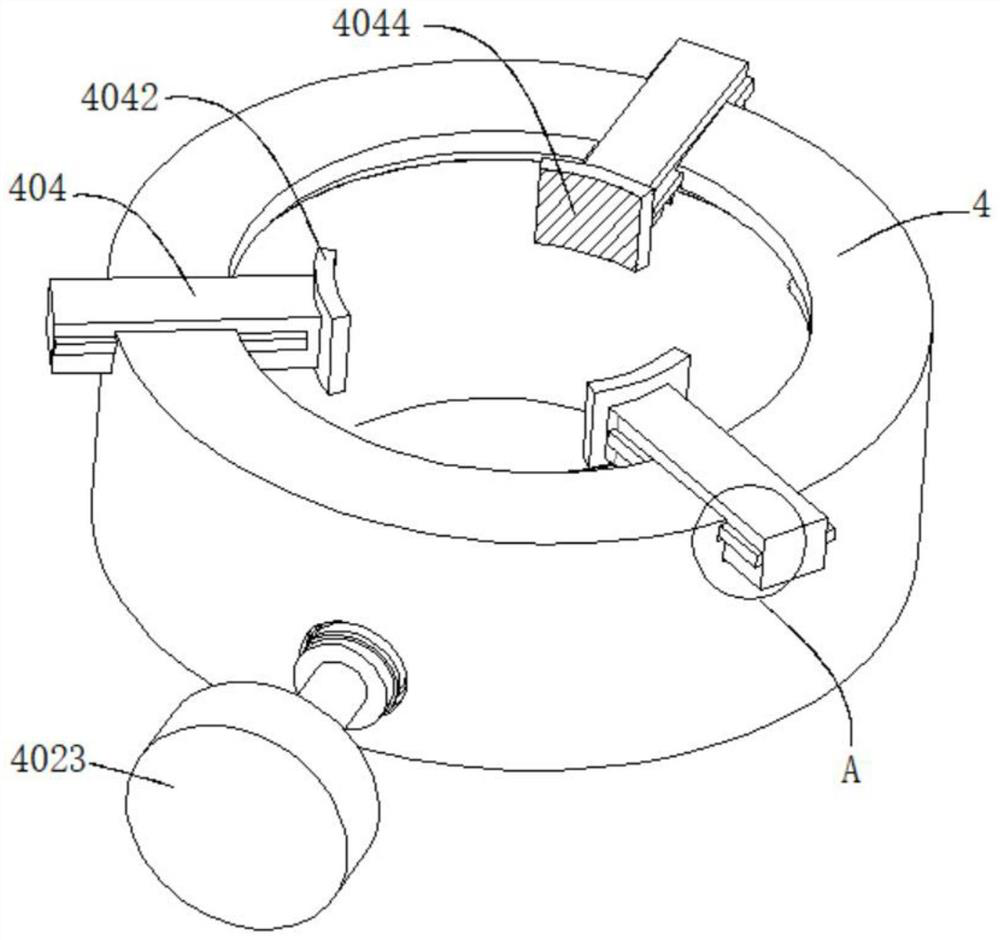

[0039]refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 , an assembled connection assembly for a steel structure house, comprising a connection housing 1, a steel pipe 3 connected to the inner wall of the connection housing 1, a cross column 2 connected to the inner wall of the connection housing 1, a blind hole 201 dug on the outer wall of the cross column 2, and the steel pipe 3 sliding Connected in the blind hole 201, the connecting shell 1 and the cross column 2 are dug with the outer wall of the steel pipe 3 to have a first threaded hole 202 that matches, the inner wall of the first threaded hole 202 is movably connected with the first bolt 2021, and the inner wall of the connecting shell 1 Also connected to the fixed disk 4, the fixed disk 4 is slidingly connected with a moving block 404, the outer wall of the moving block 404 is connected with an arc-shaped plate 4042, and the arc-shaped plate 4042 is offset against the steel pipe 3, and the inner wa...

Embodiment 3

[0042] refer to Figure 2-6 , an assembled connection assembly for a steel structure house, which is basically the same as that in Embodiment 1, furthermore, the inner wall of the rotating shaft 402 is dug with a concave hole 5, and the inner wall of the concave hole 5 is slidingly connected with a moving rod 501, and the outer walls on both sides of the moving rod 501 are Connected with the second slide block 5011, the inner wall of the recessed hole 5 is dug with the second chute 502 matched with the second slide block 5011, and the end of the moving rod 501 away from the inner wall of the recessed hole 5 is connected with a threaded rod 503, and the threaded rod 503 is connected with the fixed The inner wall of the disc 4 is threaded, and the outer wall of the steel pipe 3 is drilled with a second threaded hole 301 matched with the threaded rod 503 .

[0043] In the process of turning the handle 4023, the handle 4023 drives the rotating shaft 402 to rotate through the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com