Anti-floating honeycomb core

A technology of honeycomb core and core body, which is applied in the direction of formwork/formwork/working frame, building components, and on-site preparation of building components, which can solve the problems of large influence, trouble, and floating of honeycomb cores in decoration projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

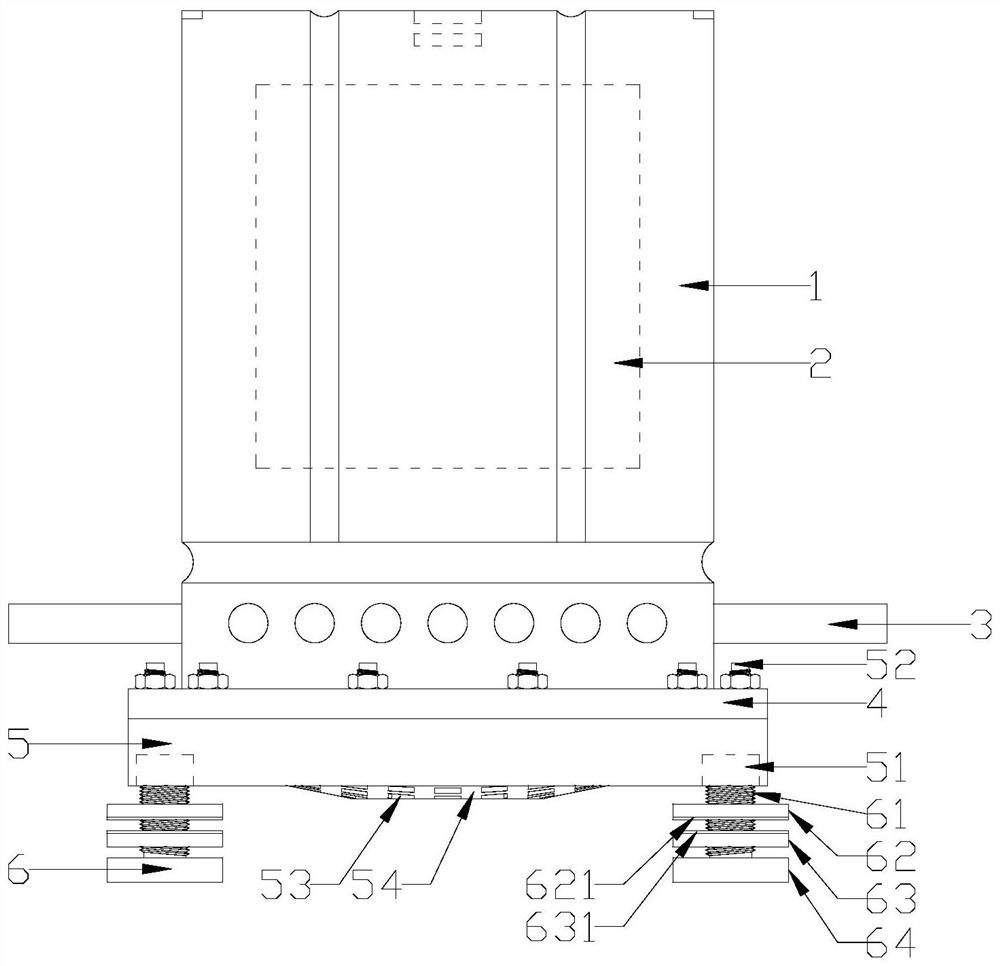

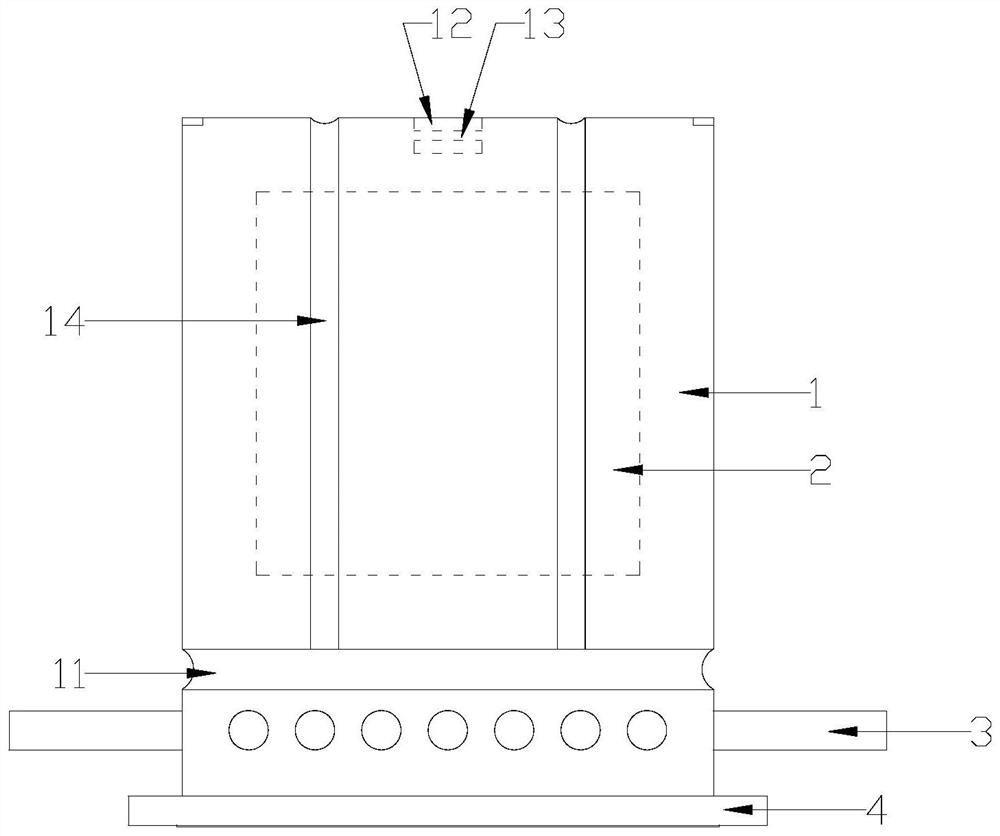

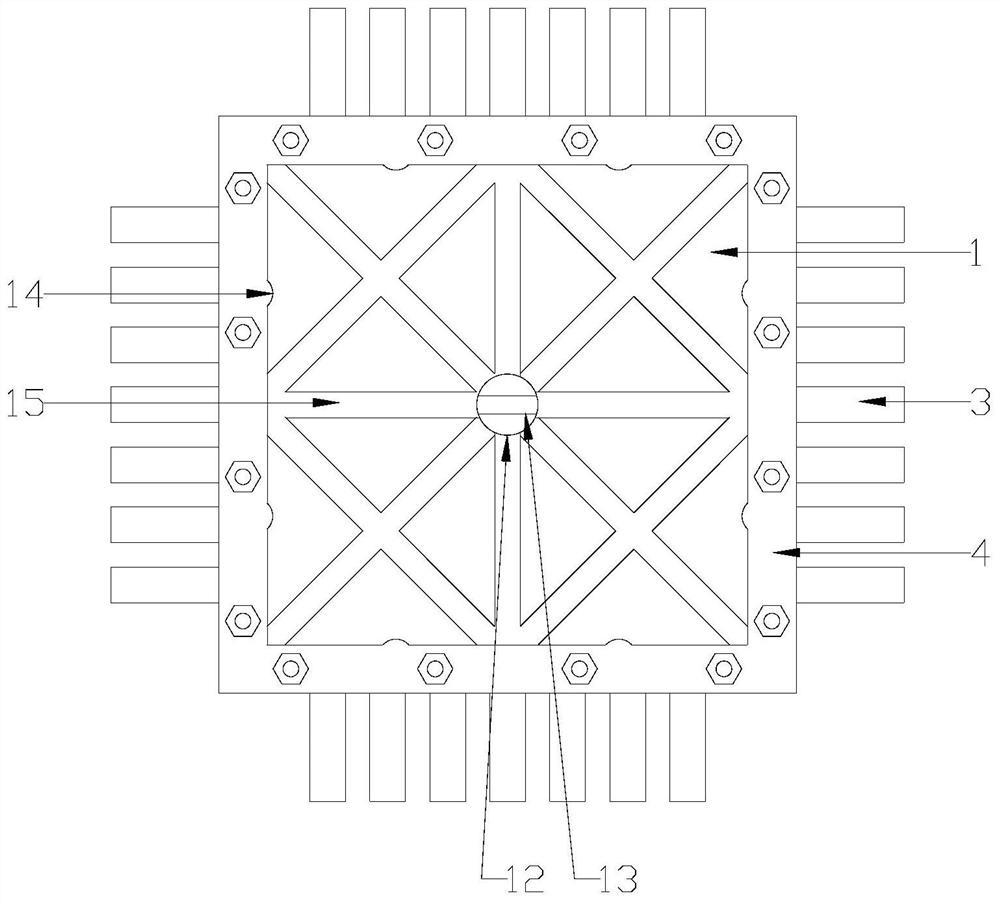

[0022] refer to Figure 1 to Figure 5 , an anti-floating honeycomb core of the present invention, comprising a honeycomb core body, a steel bar 3, a steel sheet 4, a bottom plate 5 and raising feet 6, the honeycomb core body includes a box body 1 and a core body 2, and the body of the box body 1 The outer wall is provided with a first annular groove 11 near the bottom end so as to separate the box body 1 into an upper box section and a lower box section, the core body 2 is located in the upper box section, and several steel bars 3 are evenly fixed on the lower box section in turn. On the outer wall of the box section, the steel sheet 4 is fixed on the bottom surface of the lower box section, and the bottom surface of the steel sheet 4 is provided with several circles of second annular grooves 42 from inside to outside, and the second annular groove 42 is embedded There is a rubber ring 43, the bottom surface of the steel sheet 4 is provided with several through holes 41 around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com