Anti-explosion fan capable of effectively reducing noise

An explosion-proof fan, noise technology, used in mechanical equipment, non-variable displacement pumps, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

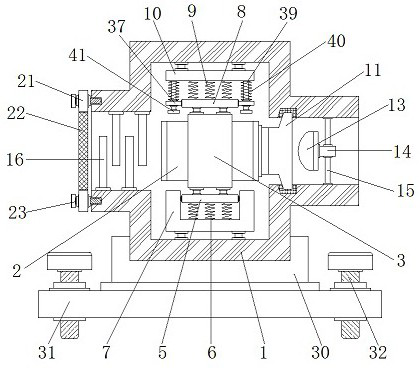

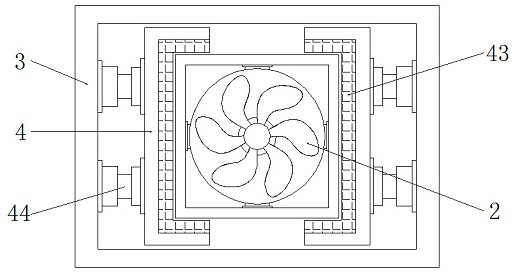

[0033] Embodiment one, such as Figure 1-8As shown, an explosion-proof fan that can effectively reduce noise according to an embodiment of the present invention includes a housing 1, an explosion-proof fan body 2 is installed inside the housing 1, and an explosion-proof fan body 2 is installed on the outer side of the explosion-proof fan body 2 Frame 3, the interior of the frame 3 is symmetrically equipped with a fixed frame 4, and the explosion-proof fan body 2 is located between the fixed frames 4, and the bottom of the frame 3 is equipped with a movable plate-5, the The bottom of the movable plate-5 is evenly equipped with some springs-6, the bottom of the spring-6 is equipped with a support base 7, and the bottom of the support base 7 is fixedly connected with the inner bottom end of the housing 1, the The top of frame body 3 is equipped with movable plate two 8, and the top of described movable plate two 8 is evenly equipped with some springs two 9, and the top of describ...

Embodiment 2

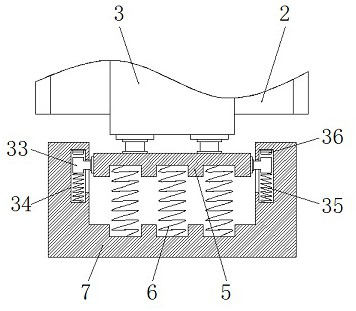

[0034] Embodiment two, such as figure 1 , 3 As shown, the support seat 7 is a U-shaped structure, and the movable plate-5 is located at the inner top of the support seat 7, and movable blocks 33 are installed on both sides of the movable plate-5, and the The positions corresponding to the movable clamping blocks 33 on both sides of the inside of the support base 7 are provided with movable clamping slots 34 compatible with the movable clamping blocks 33, and the bottoms of the movable clamping blocks 33 are equipped with Spring three 35, and the bottom of described spring three 35 is all fixedly connected with the bottom of described movable card groove 34, and the top of described movable card groove 34 is all equipped with buffer block 36; Through described movable card block 33 and described The interaction between the movable card slot 34, the spring three 35 and the buffer block 36 can further improve the shock resistance of the movable plate one 5, thereby enabling the ...

Embodiment 3

[0035] Embodiment three, such as figure 1 , 4 As shown, the two sides of the movable plate 8 are equipped with movable blocks 37, and the middle part of the movable block 37 is equipped with a positioning sleeve 38, and the inside of the positioning sleeve 38 is equipped with a positioning rod 39. , and the top of the positioning rod 39 is fixedly connected with the bottom of the fixed plate 10, the top of the movable block 37 and the outside of the positioning rod 39 are all sleeved with a spring four 40, the positioning rod 39 Limit stoppers 41 are installed at the bottom of the bottom; through the interaction between the movable block 37 and the positioning sleeve 38 and the positioning rod 39 and the spring four 40, the shock resistance of the movable plate two 8 can be further improved , so that the explosion-proof fan body 2 can achieve a better shockproof effect, and can further reduce the generation of noise, thereby facilitating to better meet people's use needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com