An in-furnace conveying device with good anti-black mark effect for round steel heating furnace

A technology of conveying device and heating furnace, applied in the field of heating furnace, can solve the problem of uneven heating of steel billets, and achieve the effects of preventing uneven heating, novel structure, and easy maintenance and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

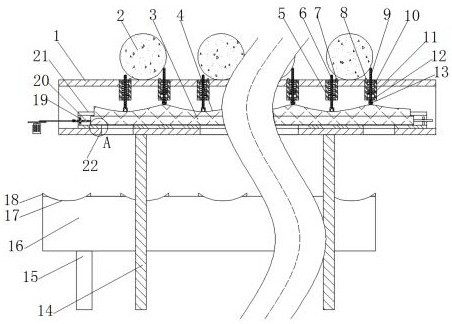

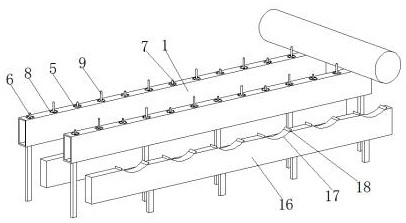

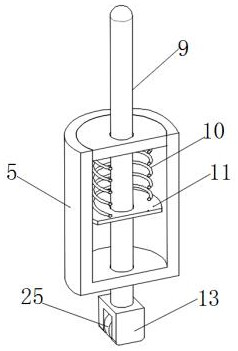

[0029] refer to Figure 1-5 An in-furnace conveying device with good anti-black mark effect for a round steel heating furnace, comprising a moving beam 16 and a fixed beam 1 in a square tubular structure, the bottom of the fixed beam 1 is fixed with a C-shaped steel slide rail 21 with an upward opening, and Slider 3 is slidably connected in the chute of C-shaped steel slide rail 21, and the both sides of slide bar 3 are all provided with the limit part 26 that matches with C-shaped steel slide rail 21 both sides, and the upper surface of slide bar 3 is fixed with The wave bar 24, the upper surface of the wave bar 24 has undulating wave grooves 4, and the middle part of the upper surface of the fixed beam 1 has installation holes distributed equidistantly, and the installation holes are equipped with built-in cavities in a cylindrical structure. The limit barrel 5, the top and the bottom of two adjacent limit barrels 5 are respectively slidably connected with the first push rod...

Embodiment 2

[0040] refer to Figure 1-2 , an in-furnace conveying device with a good anti-black mark effect for a round steel heating furnace. Compared with Embodiment 1, this embodiment also includes the side of the first top block 7 and the second top block 8 close to the billet body 2 An arc-shaped cut surface is provided, and the arc-shaped cut surface matches the outer wall structure of the billet body 2 .

[0041] It can ensure that the steel billet body 2 will not exceed the range between the first jack block 7 and the second jack block 8 due to rolling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com