Evaporation sensor

A sensor and evaporating dish technology, applied in the field of sensors, can solve the problem that the measurement results are also greatly affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

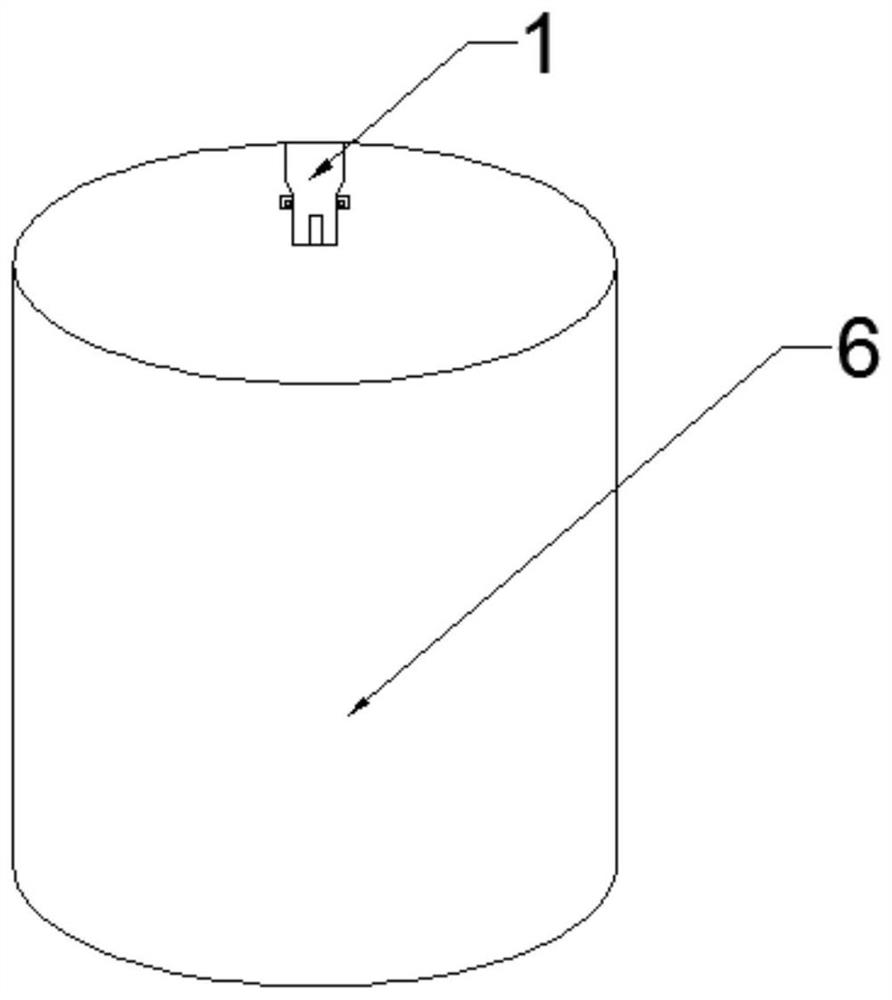

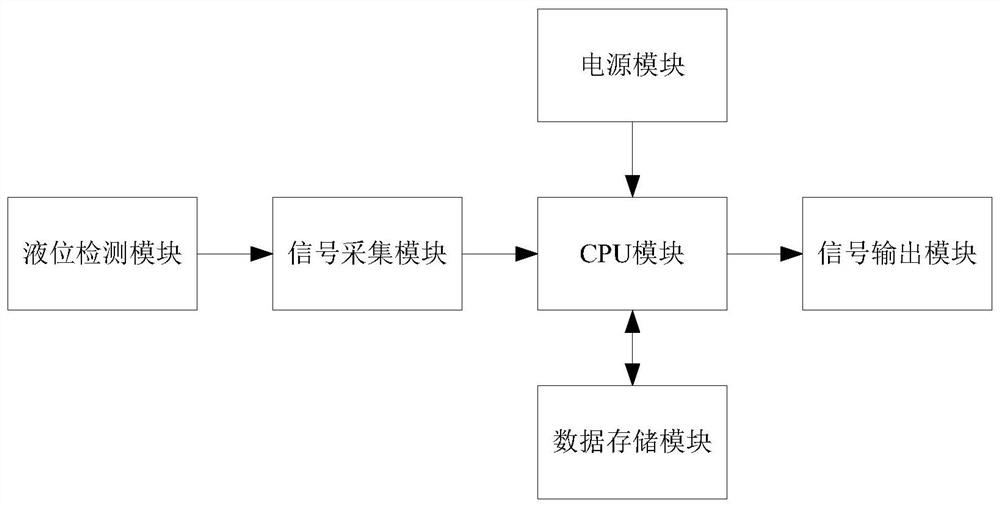

[0022] refer to Figure 1-3 , an evaporation sensor, including an evaporation sensor housing 2 and an evaporation sensor 1, the evaporation sensor 1 is fixedly installed in the evaporation sensor housing 2, and the evaporation sensor 1 includes a liquid level detection module, a signal acquisition module, a CPU module, a signal output module, and a power supply module And the data storage module, the signal acquisition module, the signal output module and the data storage module are respectively connected with the CPU module. The top is provided with a signal output plug 5. The signal output module adopts a standard RS-485 communication interface, which has strong anti-interference ability and fast data transmission rate. The CPU module uses a single-chip microcomputer as the main controller. Strong, flexible expansion, miniaturization and eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com