Liquid sample analysis method, liquid sample analysis device and liquid feeding method

An analysis method and specimen technology, applied in the direction of sampling devices, analysis materials, measuring devices, etc., can solve the problem of not being able to fully observe the formed components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

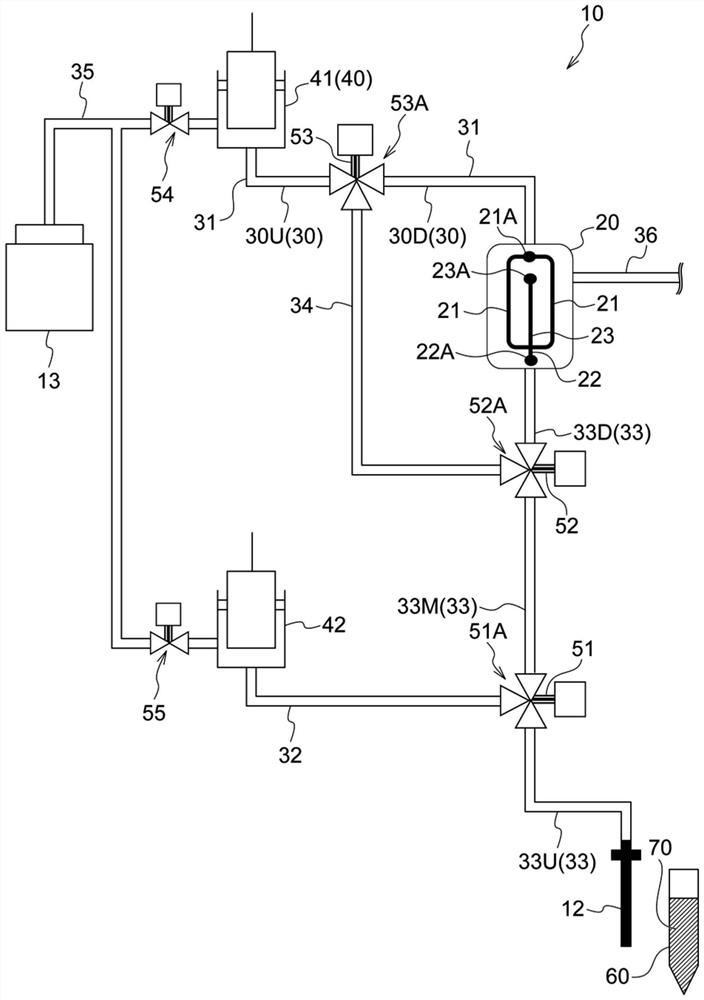

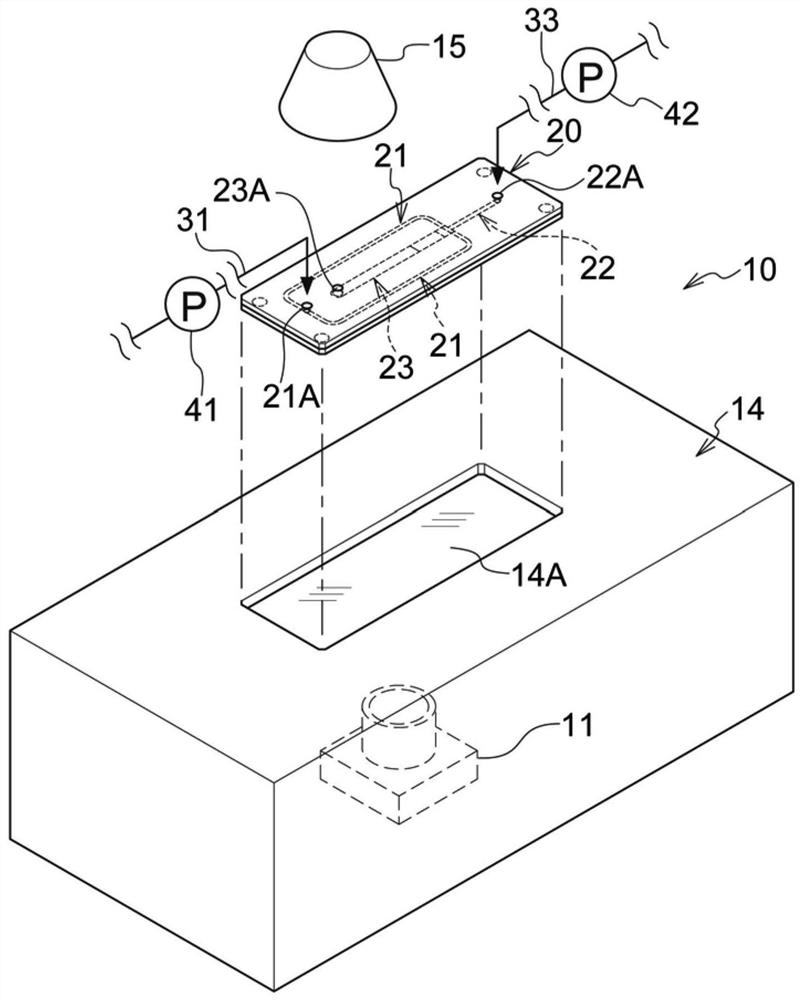

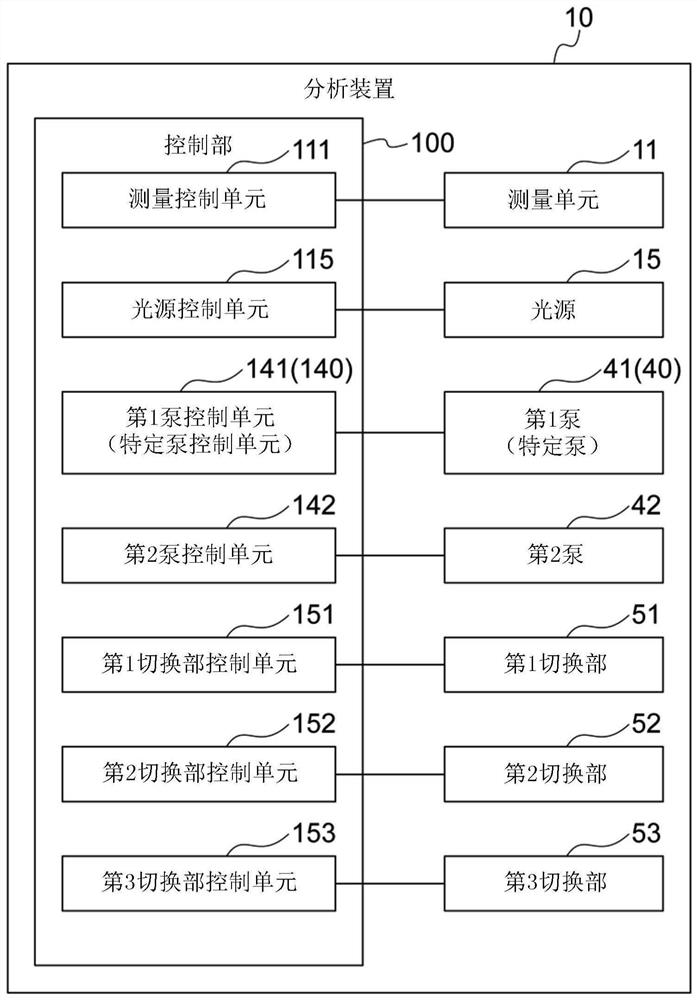

[0079] figure 1 A first embodiment of the analysis device 10 that uses urine as the sample 70 and analyzes the formed components in the urine is schematically shown. In the present embodiment, a sheath fluid supply channel 31 and a sample supply channel 33 are connected as a channel flowing into the flow cell 20 . In addition, a waste liquid path 36 is also connected as a flow path from the flow cell 20 . In addition, for the sake of convenience, in the description of the first embodiment, the analyzer 10 that analyzes the formed components in urine is used, but the sample 70 in the first embodiment is not limited to urine.

[0080] [Structure of Analysis Device 10]

[0081] The flow cell 20 is preferably made of a light-transmitting material (such as synthetic resins such as polymethyl methacrylate resin, cycloolefin polymer resin, polydimethylsiloxane resin, and polypropylene resin, or glass with visible light permeability of More than 90% of the material) is formed. The...

no. 2 Embodiment approach

[0119] Figure 13 A second embodiment of an analysis device 10 that analyzes formed components in urine using urine as a sample 70 is schematically shown. The second embodiment differs from the first embodiment in that a third switching unit 53 is provided on the sample extruding channel 32 , and the branch channel 34 connects the sample supply channel 33 and the sample extruding channel 32 . connect them. In this embodiment, as in the first embodiment, a sheath fluid supply channel 31 and a sample supply channel 33 are connected as channels for flowing into the flow cell 20 . In addition, a waste liquid path 36 is also connected as a flow path from the flow cell 20 . In addition, for the sake of convenience, in the description of the second embodiment, the analyzer 10 that analyzes the formed components in urine is used, but the sample 70 in the second embodiment is not limited to urine.

[0120] [Structure of Analysis Device 10]

[0121] The structure of the flow cell 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com