Special grease used for hard candies, and preparation method and application of special grease

A special oil and grease technology, which is applied in the field of hard candy special oil and its preparation and application, can solve the problems of candy sugar content, high calorie, limit the range of candy consumption, affect sensory quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

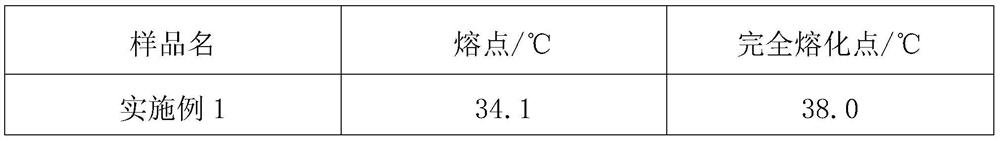

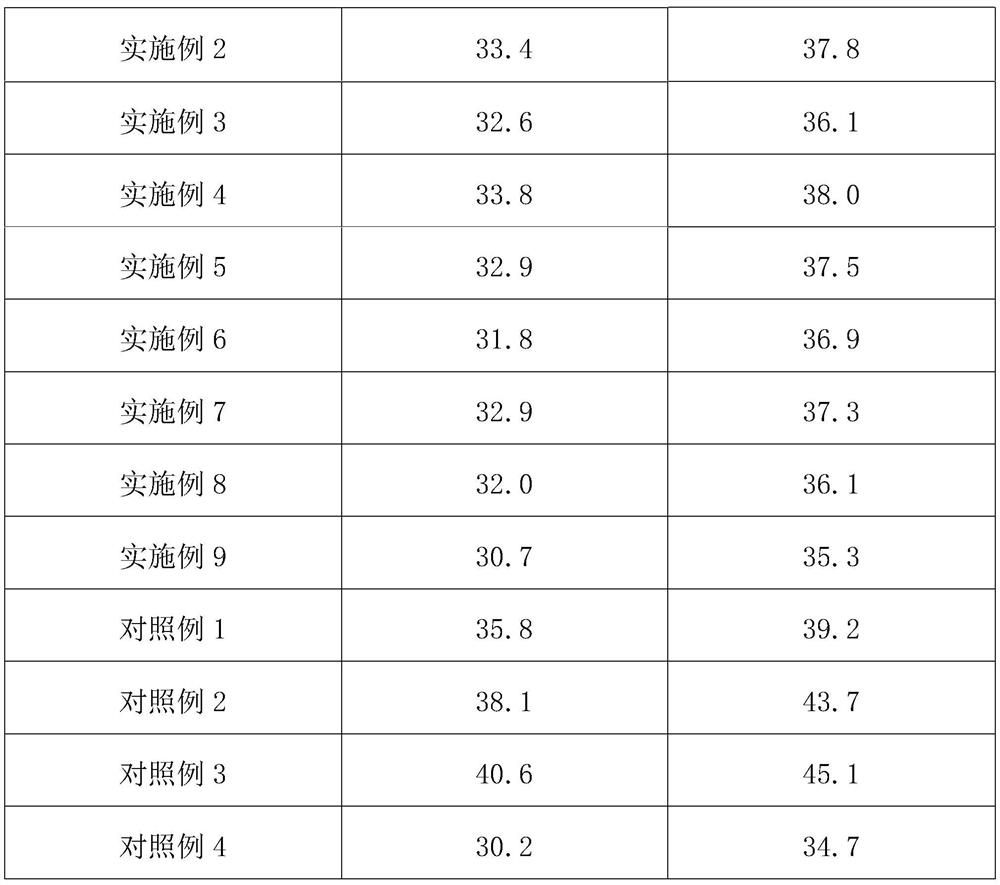

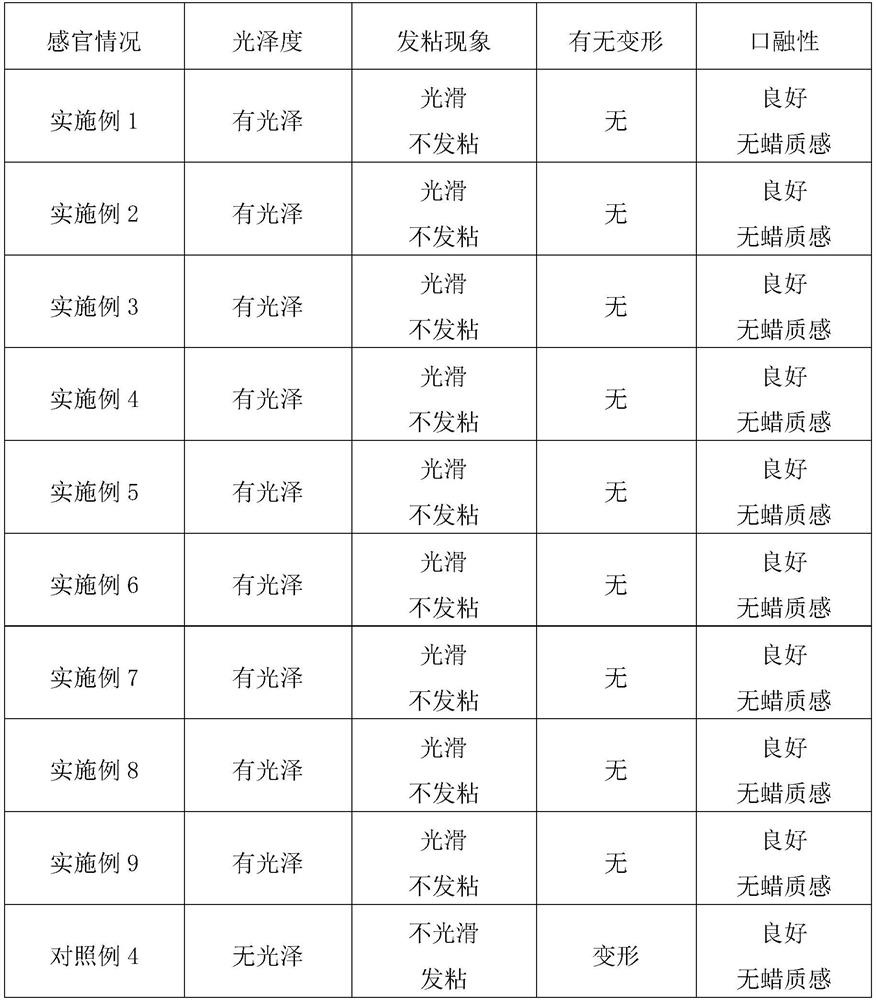

Embodiment 1

[0032] Heat the palm kernel oleyl diglyceride at 75°C to completely melt the raw material oil; cool the raw material oil to 40°C for 10 minutes, then cool down to 15°C to generate crystal nuclei and keep it for 8 minutes; place it in a quenching kneader Stir at a speed of 100r / min for 10 minutes to obtain kneaded oil; place the kneaded oil in a refrigerator at 3°C for 10 minutes, and then place it at 25°C for 48 hours to obtain special oil for candy. The melting point and complete melting point of the sample were determined by the open capillary method GB5536-85.

Embodiment 2

[0034] Heat coconut oil-based diglyceride at 75°C to completely melt the raw material oil; cool the raw material oil to 40°C for 10 minutes, then cool down to 15°C to generate crystal nuclei and keep it for 8 minutes; place it in a quenching kneader Stir at a speed of 100r / min for 10 minutes to obtain kneaded oil; place the kneaded oil in a refrigerator at 3°C for 10 minutes, and then place it at 25°C for aging for 48 hours to obtain special oil for candy. The melting point and complete melting point of the sample were determined by the open capillary method GB5536-85.

Embodiment 3

[0036] Heat palm oleyl diglyceride at 75°C to completely melt the raw material oil; cool the raw material oil to 40°C for 10 minutes, then cool down to 15°C to generate crystal nuclei and keep it for 8 minutes; put it in a quenching kneader Stir at a speed of 100r / min for 10 minutes to obtain kneaded oil; place the kneaded oil in a refrigerator at 3°C for 10 minutes, and then place it at 25°C for 48 hours to obtain special oil for candy. The melting point and complete melting point of the sample were determined by the open capillary method GB5536-85.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com