Building construction paint blending device with good mixing effect

A technology for building construction and mixing effects, which is applied to mixers, mixers with rotating stirring devices, transportation and packaging, etc. It can solve the problems of poor paint mixing effect, long time, and affecting the user's experience of using the mixing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

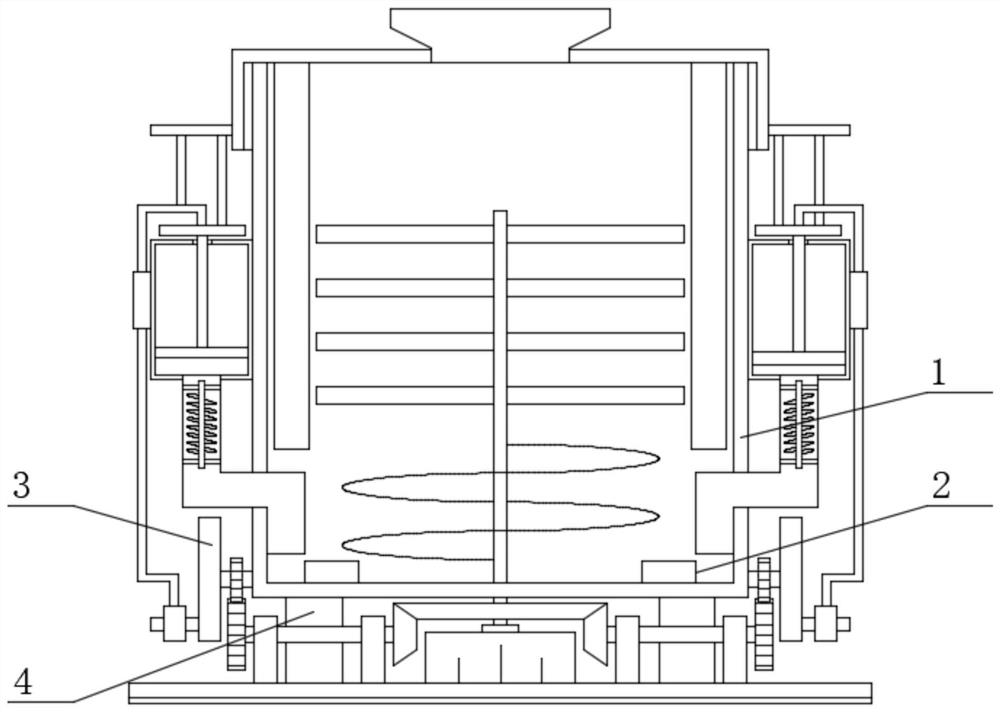

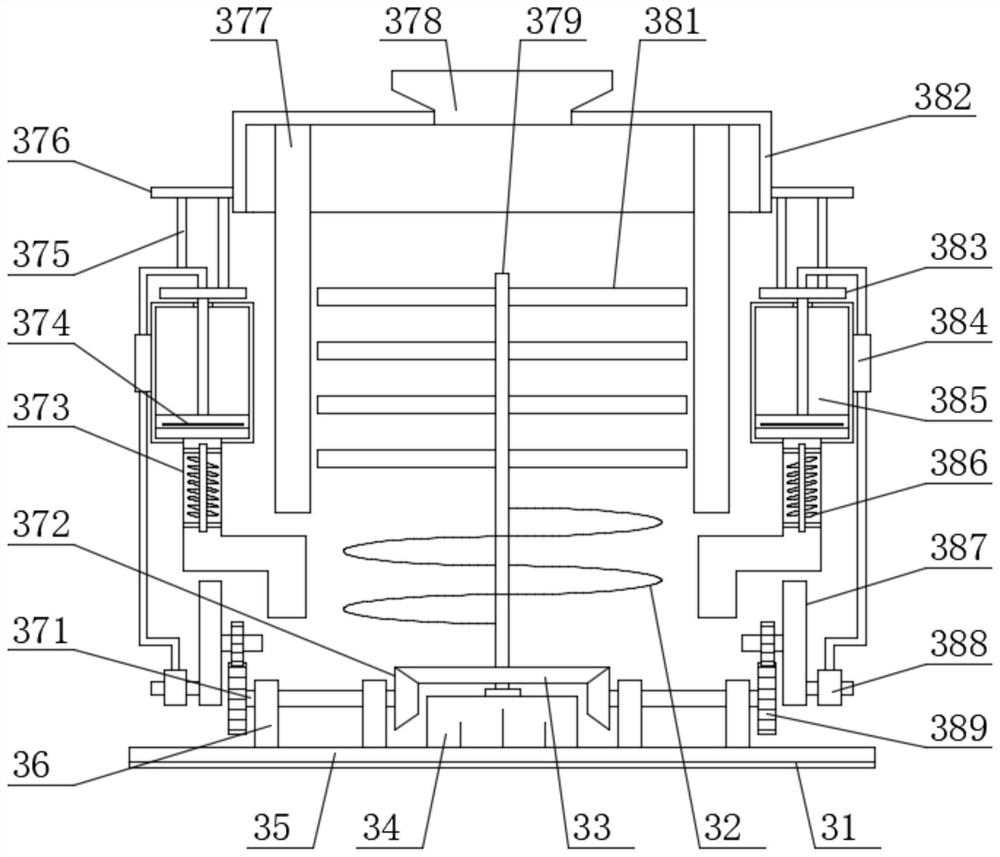

[0023] see Figure 1-Figure 3 , the present invention provides a technical solution: a paint blending device with good mixing effect for building construction, comprising a material storage box 1, the bottom of the material storage box 1 is welded with a discharge pipe 2, and the lower surface of the material storage box 1 is two The end is provided with a support foot 4, the bottom of the storage box 1 is provided with a stirring mechanism 3, the stirring mechanism 3 includes a support base plate 35, a drive motor 34 is provided in the middle of the upper surface of the support base plate 35, and the output end of the drive motor 34 is provided with a second Transmission shaft 379, the top of the second transmission shaft 379 is provided with a stirring rod 381, and the bottom end of the second transmission shaft 379 is provided with a helical blade 32;

[0024] Both sides of the second transmission shaft 379 are provided with a piston cylinder 385, the piston cylinder 385 is...

Embodiment 2

[0031] On the basis of Embodiment 1, in order to make the limiting effect of the limiting sleeve 384 better, in this embodiment, preferably, the limiting sleeve 384 is slidably connected with the transmission member 388, and the limiting sleeve 384 is connected to the piston cylinder 385 is fixedly connected by welding;

[0032] In order to make the use of the support member 36 more reliable, in this embodiment, preferably, the bottom end of the support member 36 is fixedly connected to the support bottom plate 35 by welding, and the top end of the support member 36 is provided with a shaft corresponding to the first transmission shaft 371. bearing;

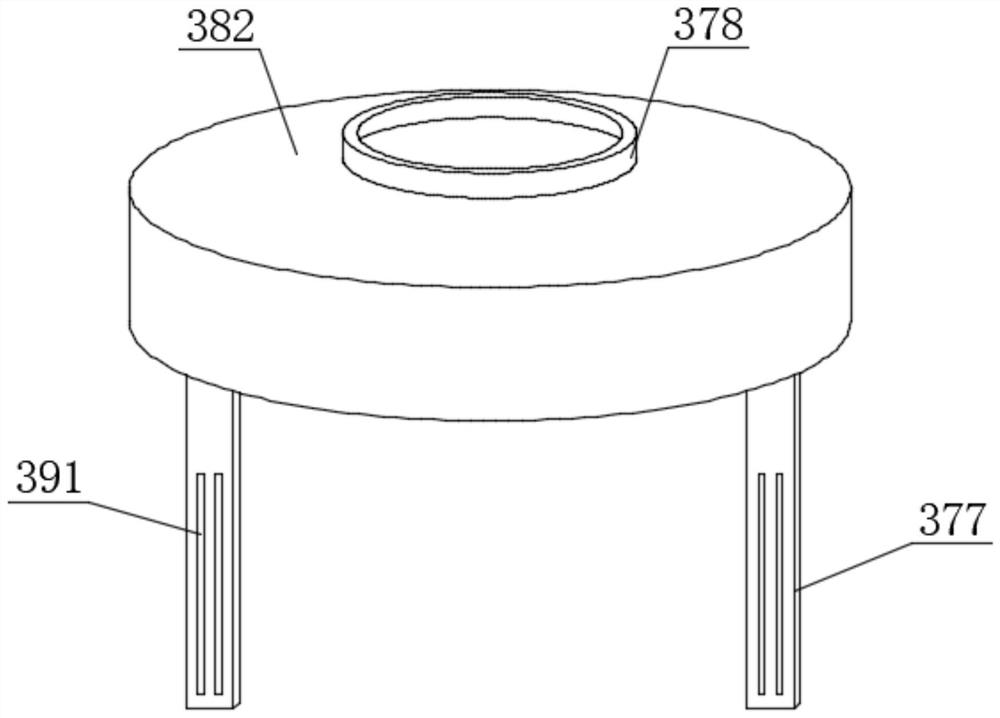

[0033] In order to make the structural strength of the feed hopper 378 better, in the present embodiment, preferably, the material of the feed hopper 378 is stainless steel, in order to make the use of the feed hopper 378 more firm, the bottom of the feed hopper 378 and the top cover 382 is fixedly connected by welding;

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com