High-efficiency spray structure of environment-friendly spray tower

A spray tower, an environmentally friendly technology, applied in the field of high-efficiency spray structures, can solve problems such as leakage, reduced purification efficiency, and shaking of connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

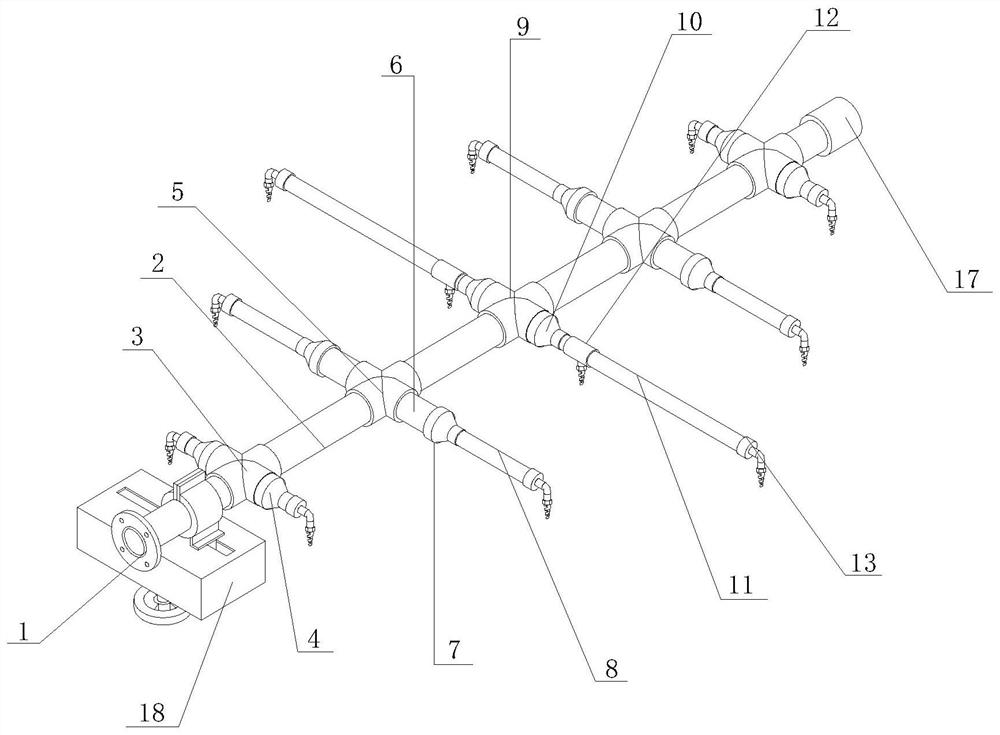

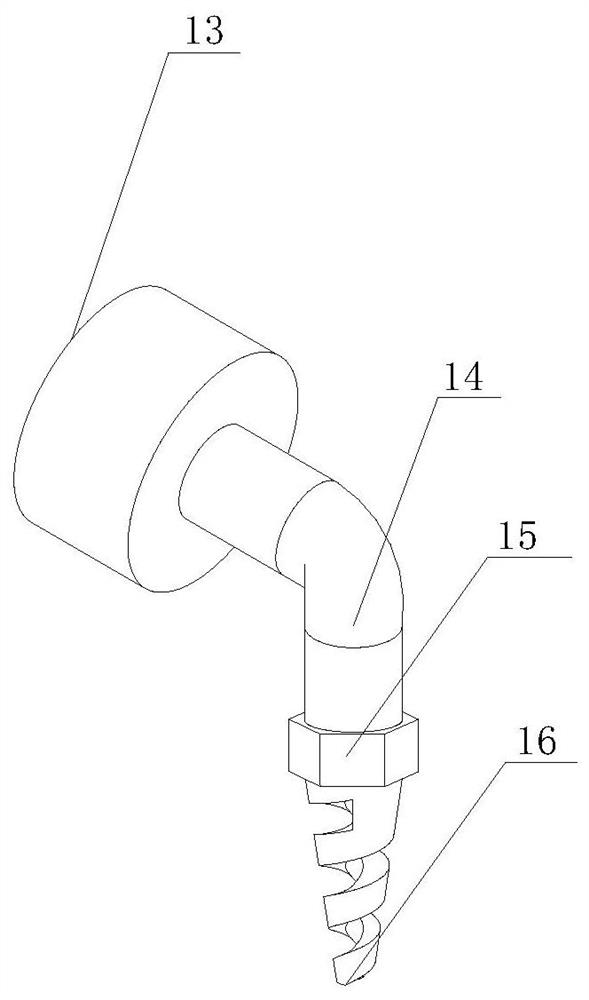

[0029] see Figure 1-2 , the present invention provides an efficient spraying structure of an environment-friendly spray tower through improvement, including a flange 1 and a reinforcement device 18, the right end of the flange 1 is attached to the left end of the water pipe 2, and the water pipe 2 is connected to the first connector 3 The middle part is plugged in, and the water pipe 2 is plugged in the middle part of the second connector 5, the front end of the first connector 3 is plugged into the rear end of the first connecting cover 4, and the front end of the second connector 5 is plugged into the rear end of the first connecting pipe 6 , the front end of the first connection pipe 6 is connected to the rear end of the second connection cover 7, the front end of the second connection cover 7 is connected to the rear end of the second connection pipe 8, the middle part of the water pipe 2 is provided with a third connector 9, and the third connector 9 The front end is con...

Embodiment 2

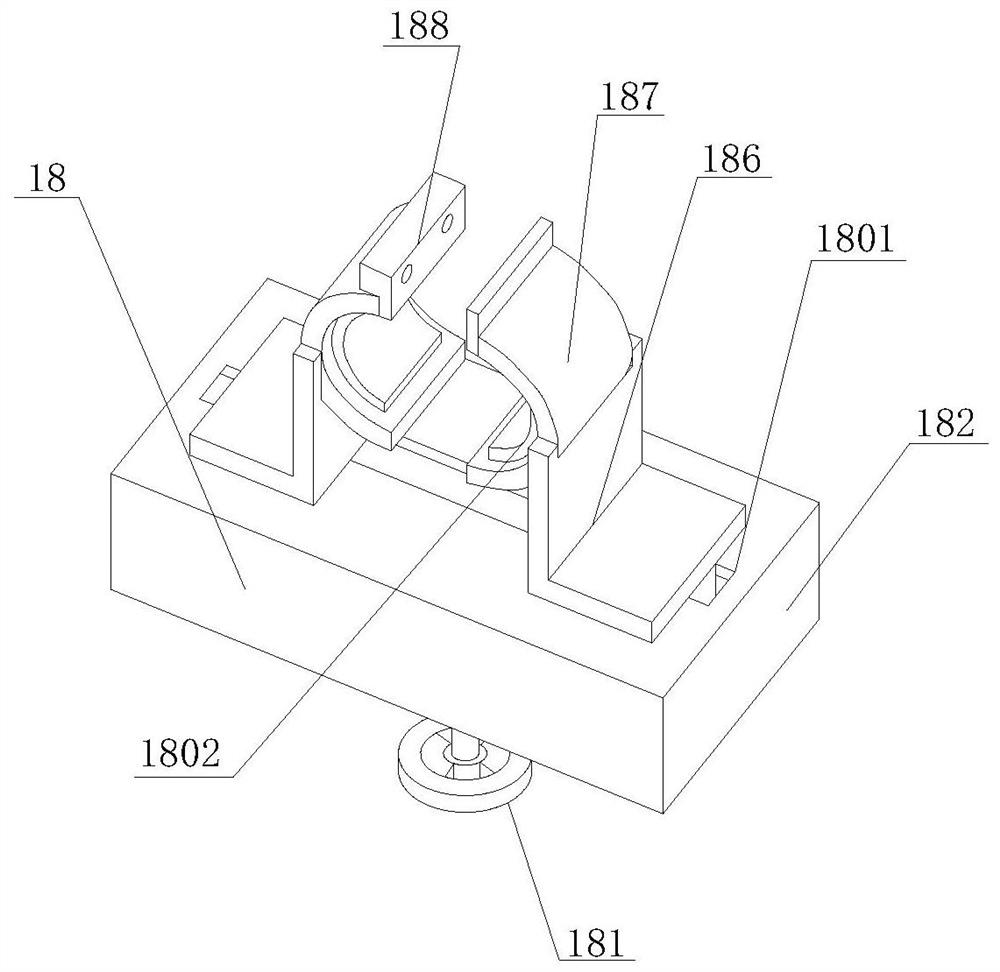

[0034] The present invention provides a high-efficiency spraying structure of an environment-friendly spraying tower through improvement. The lower end of the L-shaped plate 186 is offset against the upper end of the housing 182, which is conducive to sliding installation with the chute 1801 and the stability of the lifting device. The lower end of the slide rail 1853 Fastened to the inner front end of the housing 182, it is beneficial to realize the fixing effect, and the upper end of the sliding plate 1856 is slidably installed with the upper end of the housing 182, which is beneficial to improving the stability of the sliding plate 1856 when moving.

[0035] The present invention provides a high-efficiency spray structure of an environment-friendly spray tower through improvement, and its working principle is as follows;

[0036] First, before use, the first connector 3, the second connector 5 and the third connector 9 are connected to the water pipe 2 in sequence, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com