Multi-station stamping device with automatic positioning function and using method thereof

A stamping device and automatic positioning technology, applied in positioning devices, cleaning methods using gas flow, feeding devices, etc., can solve the problems of automatic positioning of stamping parts, offset of stamping parts, crushing of stamping parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

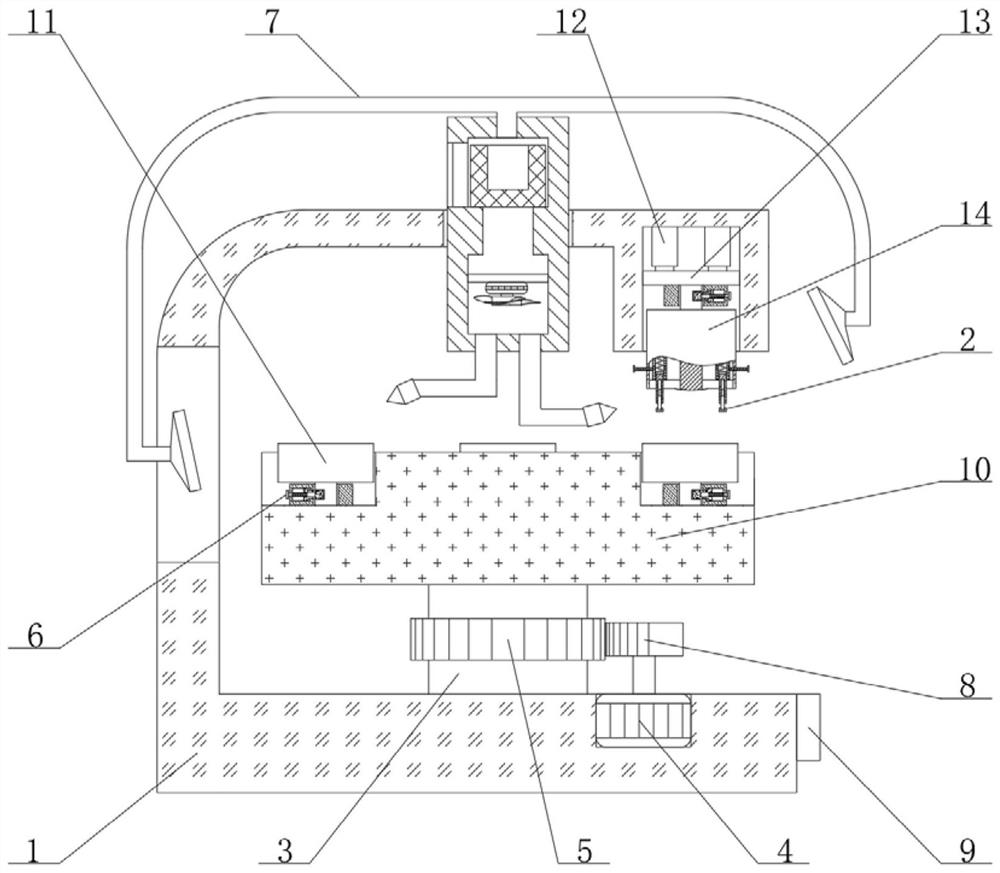

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , the present invention provides a technical solution:

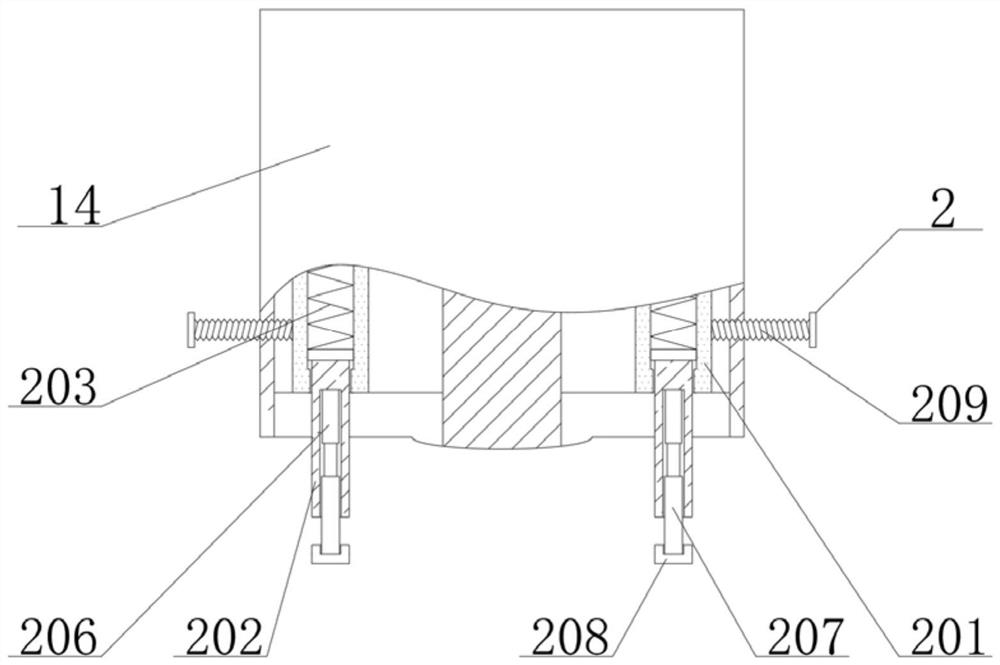

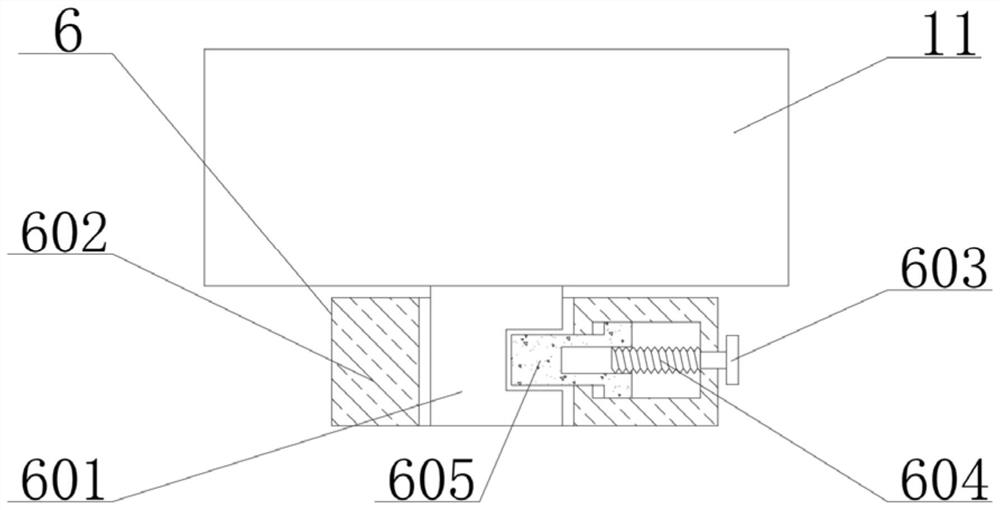

[0031]A multi-station stamping device with automatic positioning function and its use method, comprising a fixed frame 1, a positioning device 2, a connecting device 6 and a cleaning device 7, the inner side of the bottom end surface of the fixed frame 1 is rotatably connected with a rotating shaft 3, and the inner side of the fixed frame 1 The motor 4 is socketed on the right side of the bottom end, the end of the main shaft of the motor 4 is fixedly connected with the driving gear 8, the outside of the driving gear 8 is meshed with the driven gear 5, and the driven gear 5 is fixedly connected with the rotating shaft 3, and the driving gear 8 is disposable The angle of rotation is 360°, and the angle of one-time rotation of the driven gear 5 is 90°. This setting realizes the multi-station precision stamping of the device. There is a d...

Embodiment 2

[0040] The same parts as those in Embodiment 1 will not be repeated in Example 2. The difference is that when stamping a stamped part with an irregular and uneven top, after adjusting its positioning position according to the size of the stamped part, The controller 9 controls the punch 14 to drop to the lowest point. At this time, the four springs 203 are compressed to different degrees at the same time, and the pressure plate 204 will continuously press the pressure sensor 205. At this time, the pressure values sensed by the four pressure sensors 205 will be different. , when the pressure value sensed by a pressure sensor 205 is greater than the set value, the electric telescopic rod 206 at the corresponding position will continue to shrink, thereby continuously reducing the pressure value sensed by the pressure sensor 205 until it is the same as the set value. When the pressure value sensed by the pressure sensor 205 is less than the set value, the electric telescopic rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com