Welding ball valve test fixture and use method thereof

A technology for testing fixtures and ball valves, which can be used in mechanical valve testing, manufacturing tools, workpiece clamping devices, etc., and can solve problems such as time-consuming, laborious, cracking, and poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

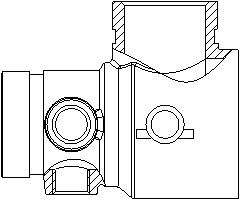

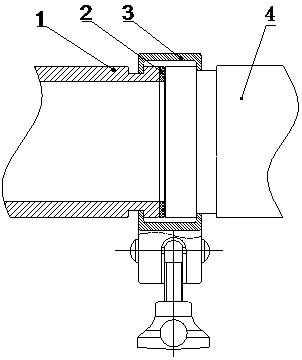

[0036] like Figure 1-2 As shown, at present, the welding joint 4 is connected to the test line. Generally, the welding joint 4 is docked with the chuck 1, and an O-ring 2 is arranged between the welding joint 4 and the chuck 1, and then the clamp is clamped by the clamp 3. The head 1 and the welding joint 4 are locked, considering the problems in the background technology, such as Figure 3-4 As shown, this embodiment proposes a welded ball valve test fixture, including a chuck 1, a stepped hole is opened inside the chuck 1, a welded joint 4 is inserted in the stepped hole, and a welded joint 4 is provided on the inner wall of the stepped hole to cooperate with the welded joint 4. The O-ring 2 plays a sealing role; the outer wall of the welding joint 4 is provided with a card slot 41, and the chuck 1 is provided with a slide hole communicating with the stepped hole, and a lock tongue 8 is slidably connected to the slide hole, and the lock tongue 8 cooperates with the card Co...

Embodiment 2

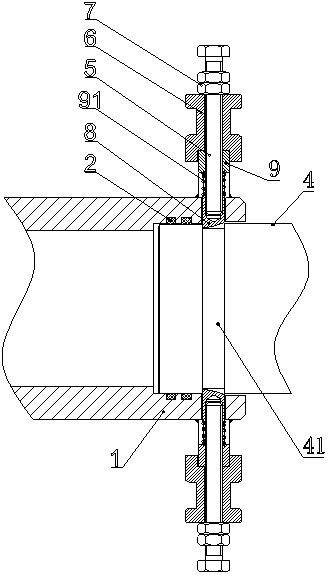

[0047] like Figure 5-6 As shown, on the basis of Embodiment 1, this embodiment proposes a welded ball valve test fixture, wherein the connector 5 is a bolt; the spring 91 seat 9 is also connected to the buckle 6, and the buckle 6 is provided with a through cavity. The bolt extends to the outside through the cavity; the bottom of the buckle 6 is provided with a groove 61, and the end of the seat 9 of the spring 91 is clamped in the groove 61.

[0048] The bolt is also threaded with a nut 7, the nut 7 is in contact with the end face of the seat 9 of the spring 91, and the height of the dead bolt 8 can be adjusted through the nut 7.

[0049] The present invention is designed with two different deadbolt 8 driving devices, which are ingenious in design and reasonable in structure. The designed wrench adopts the principle of leverage to save labor; the designed lifting buckle 6 is more stable when the limit is fixed; no matter what kind of driving It is very convenient to use, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com