Concrete stirring device for construction

A technology of mixing device and concrete, applied in cement mixing device, clay preparation device, unloading device, etc., can solve the problems of affecting construction progress, long mixing time and slowness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

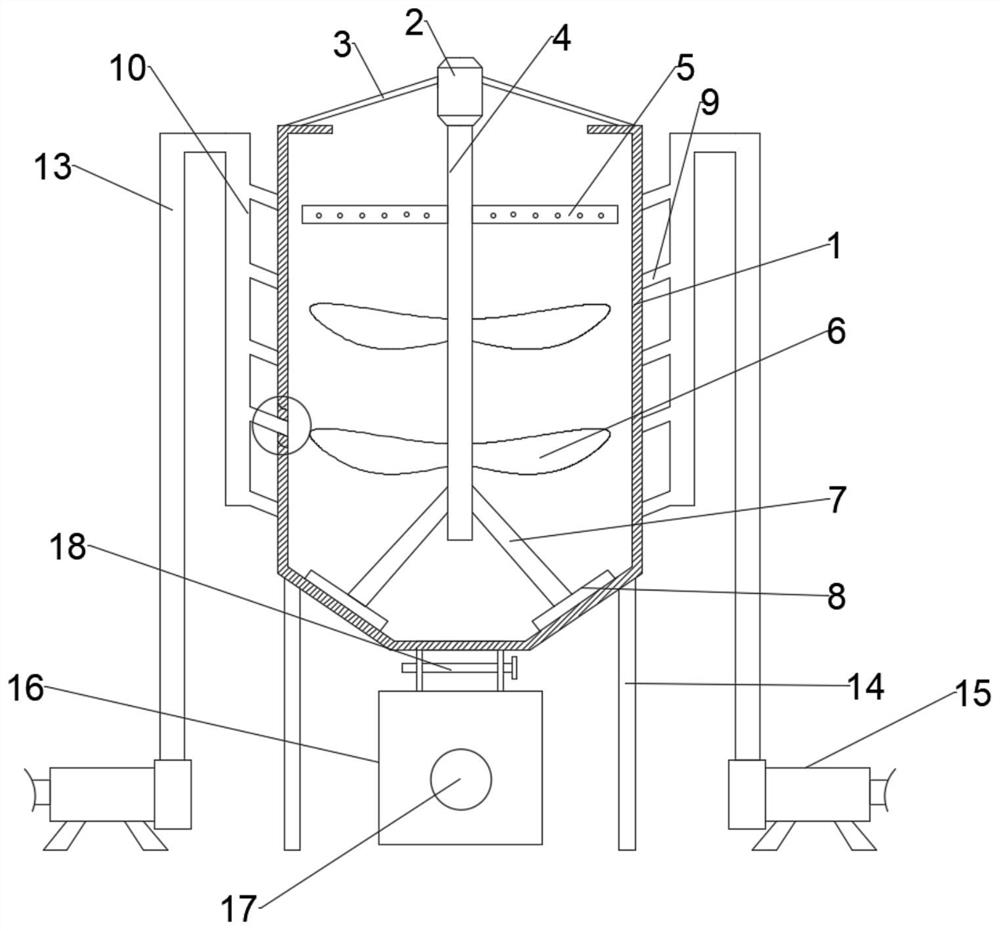

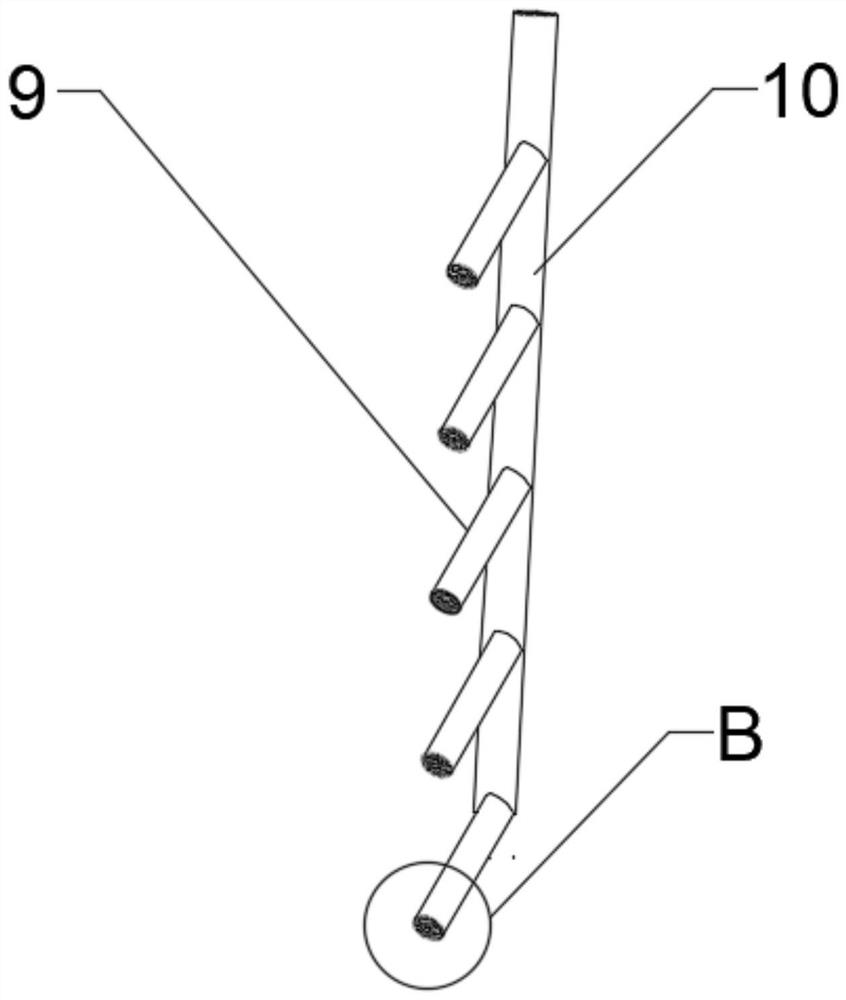

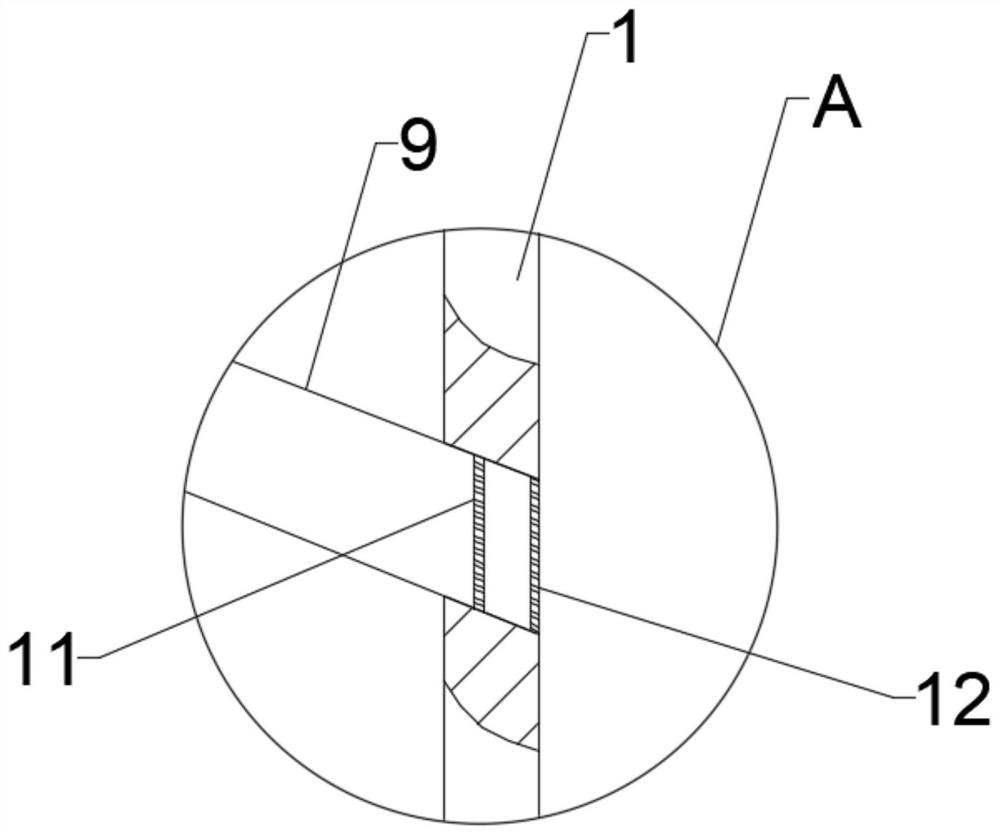

[0021] Combine Figure 1-4 , A concrete mixing device for construction, comprising a mixing tank 1 and a pillar 14, wherein the pillar 14 is fixed at the lower end of the mixing tank 1, and the pillar 14 is provided to support the mixing tank 1 to improve the stability of the mixing process. A plurality of first water pipes 9 are provided on both sides of the mixing tank 1, and one end of the plurality of first water pipes 9 on both sides penetrates the side wall of the mixing tank 1 and is connected to the inner wall of the mixing tank 1, and the other ends are connected To the second water pipe 10, a plurality of the first water pipes 9 are evenly distributed on both sides of the mixing tank 1 from top to bottom. The second water pipe 10 is connected to the booster water pump 15 through the third water pipe 13, and is The water pump 15, the third water pipe 13, the second water pipe 10, and the first water pipe 9 cooperate to inject water into the upper, middle and lower part...

Embodiment 2

[0028] Combine figure 1 , A concrete mixing device for construction, this embodiment further defines the device on the basis of the embodiment.

[0029] A delivery pump 16 is connected to the lower end of the discharge port, and a delivery pipe 17 is installed on the delivery pump 16.

[0030] Specifically, after the mixing is completed, the partition 18 is opened, and the concrete material flows into the delivery pump 16 from the discharge port, and is delivered to the construction site through the delivery pipeline 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com