Concrete powder storing device

A technology for concrete powder and storage, which is used in packaging, transportation and packaging, containers, etc., can solve the problems of multiple internal spaces, affecting the storage capacity of the storage device, and occupying the storage device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

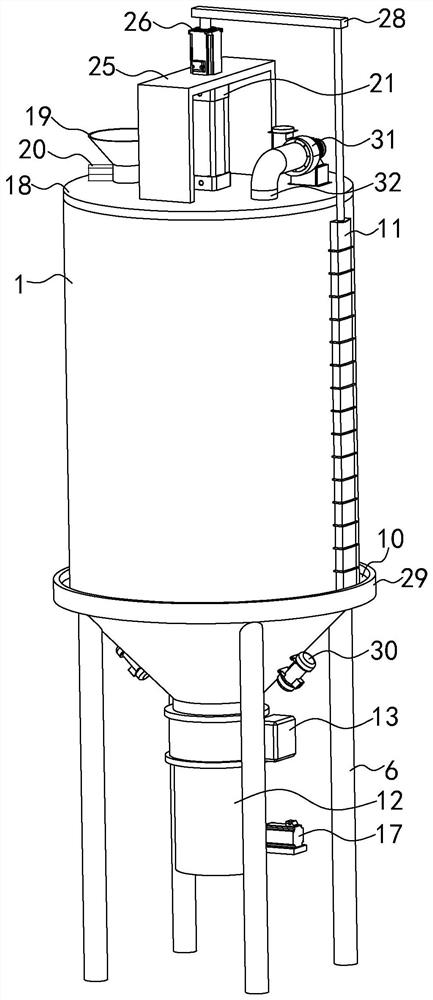

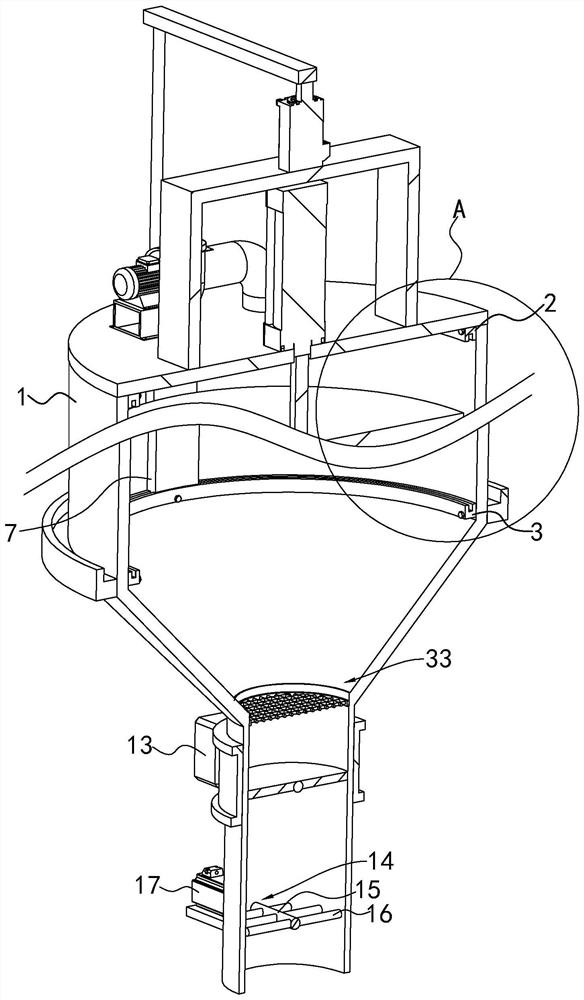

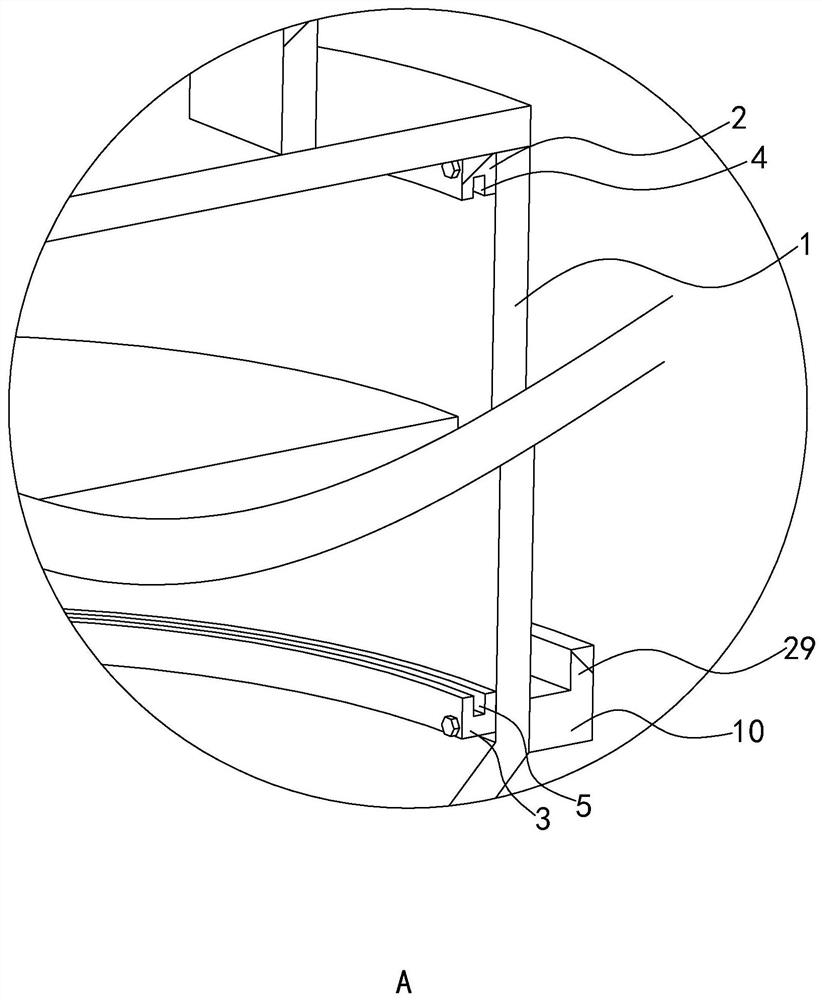

[0039] refer to figure 1 , a concrete powder storage device disclosed in the present invention includes a storage tank 1, and the upper end of the storage tank 1 is sealed with a cylinder cover 18 to ensure the sealing of the storage tank 1 and prevent the powder in the storage tank 1 The material is damp and agglomerated. The cylinder cover 18 is provided with a feeding funnel 19, which facilitates feeding in the storage tank 1 through the feeding funnel 19. The lower end of the feeding funnel 19 is provided with a feeding valve 20. By closing the feeding valve 20, the sealing performance of the storage tank 1 can be improved. The powder in the storage tank 1 is protected. The bottom end of the storage tank 1 is connected with a bracket 6 to ensure the distance from the ground and avoid damp. The bottom end of the storage tank 1 is set in an inverted cone shape, so as to prevent the bottom end of the storage tank 1 from storing materials during the discharging process of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com