Method for improving purity of finished salt of evaporation-process salt and nitrate co-production process

A technology, salt nitrate technology, which is applied in the field of improving the purity of finished salt in the process of co-production of salt nitrate by evaporation method, and can solve the problems that the purity of finished salt cannot be further purified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

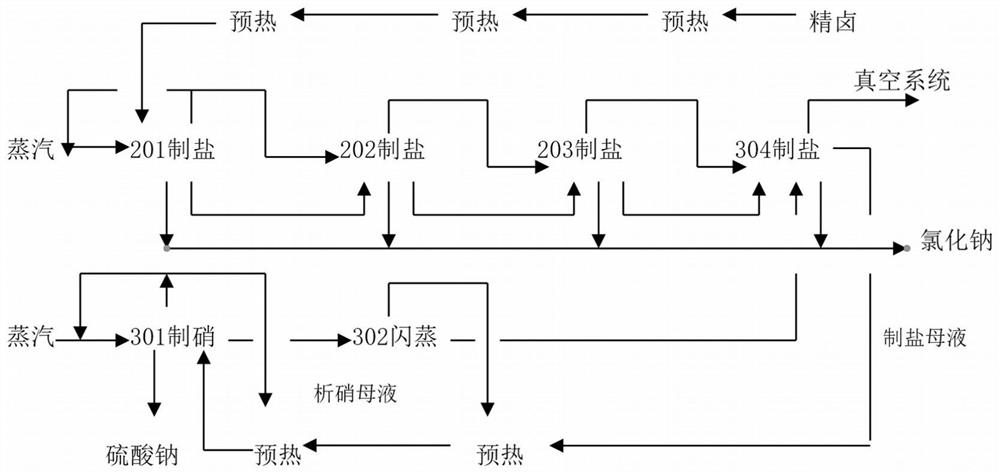

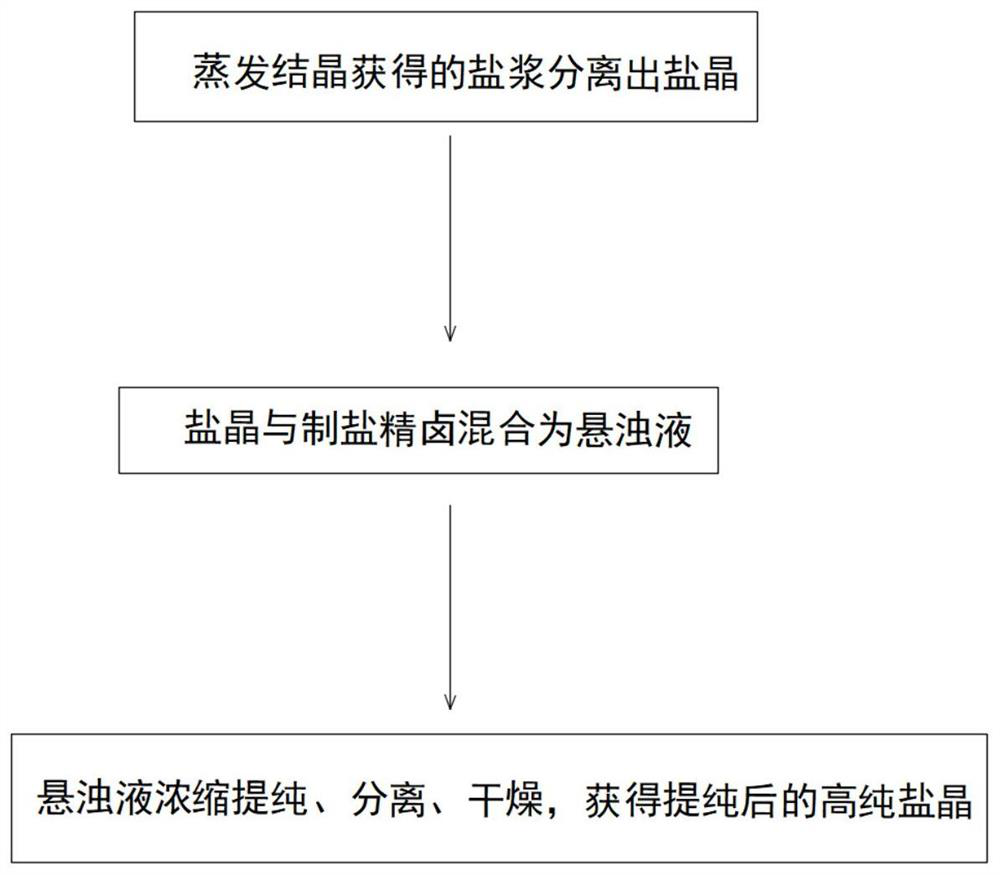

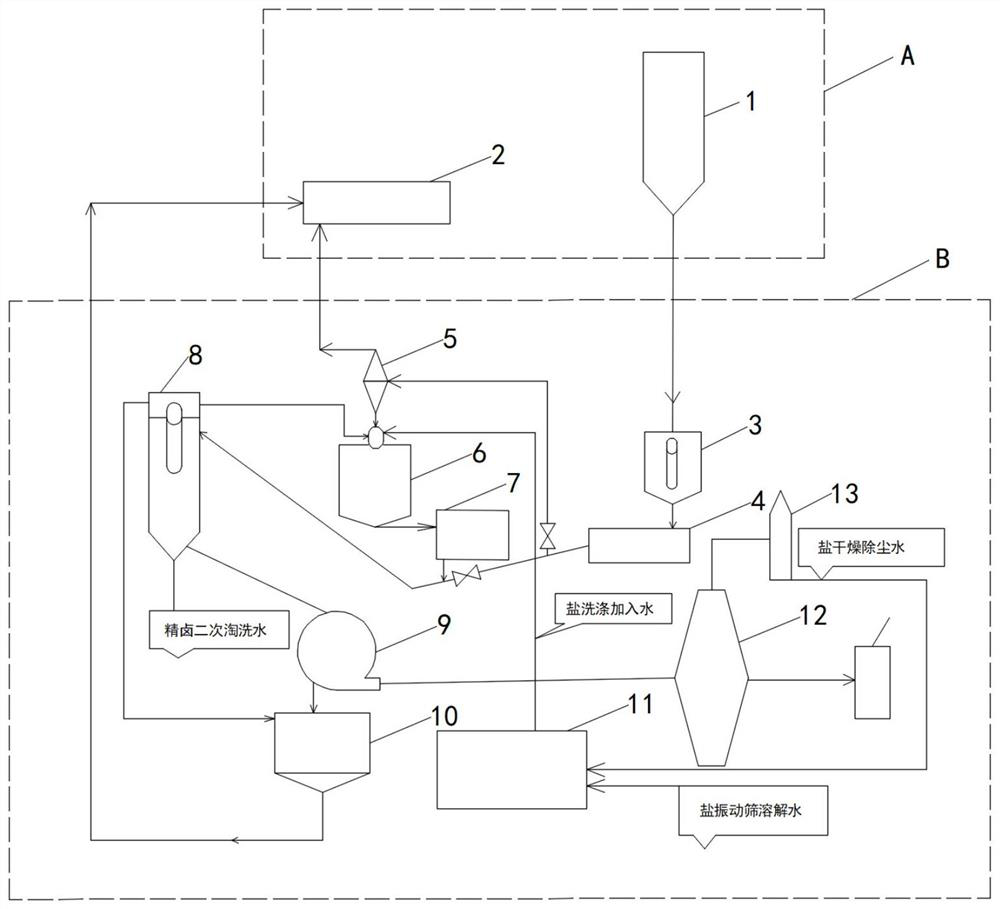

[0026] Such as figure 2 As shown, a method for improving the purity of finished salt in the evaporation co-production salt nitrate process is used in conjunction with the existing evaporation co-production salt nitrate process, and is arranged after the salt discharge leg of the evaporation crystallization tank in the existing process. Step 1: S1, separate the solid-liquid mixed phase high-concentration salt slurry obtained by evaporative crystallization in the evaporation crystallization tank to obtain solid-phase salt crystals and salt liquid; S2, combine the salt crystals obtained in step 1 with the salt-making refined brine required for evaporative crystallization Mixing to prepare a suspension containing a large amount of salt crystals; S3, concentrating, purifying, separating, and drying the suspension obtained in step 2 to obtain purified high-purity salt crystals, and mixing the resulting solution into the refined salt brine as salt nitration The original brine produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com