Integrated and safe yarn guide mechanism for twisting machine

A yarn guide mechanism and twisting machine technology, applied in textiles and papermaking, etc., can solve problems such as safety limitations, inability to change according to needs, and inability to monitor conduction status in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

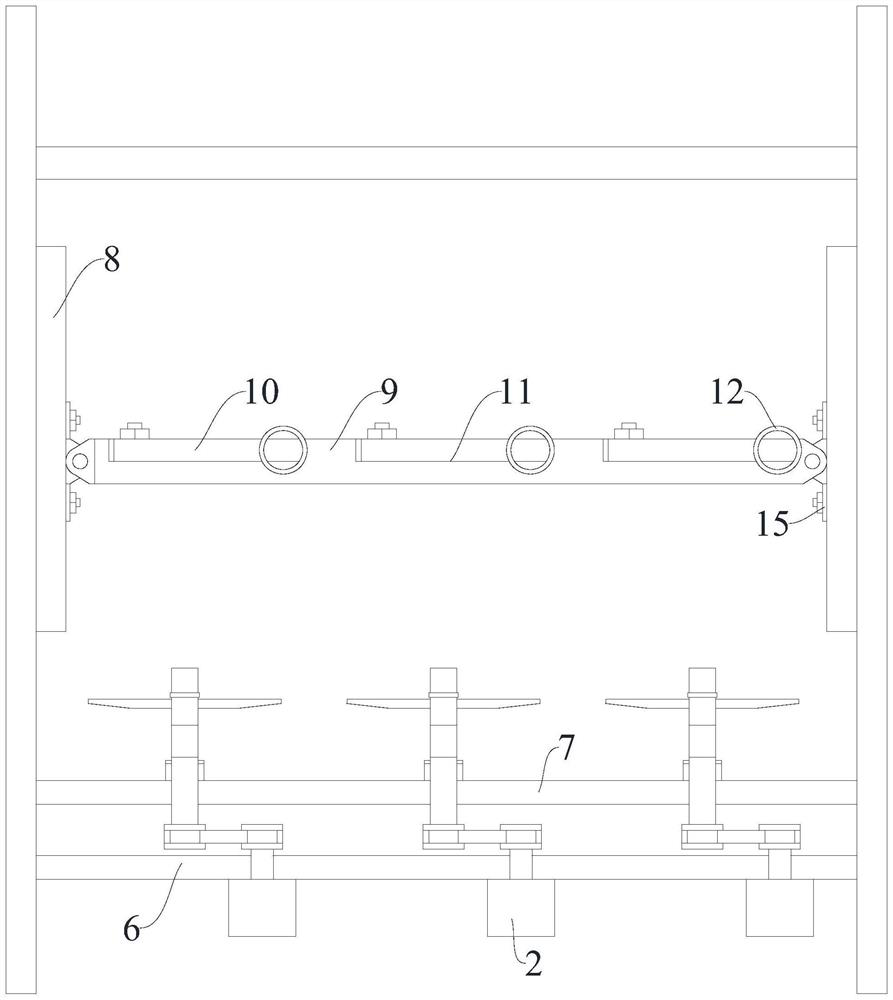

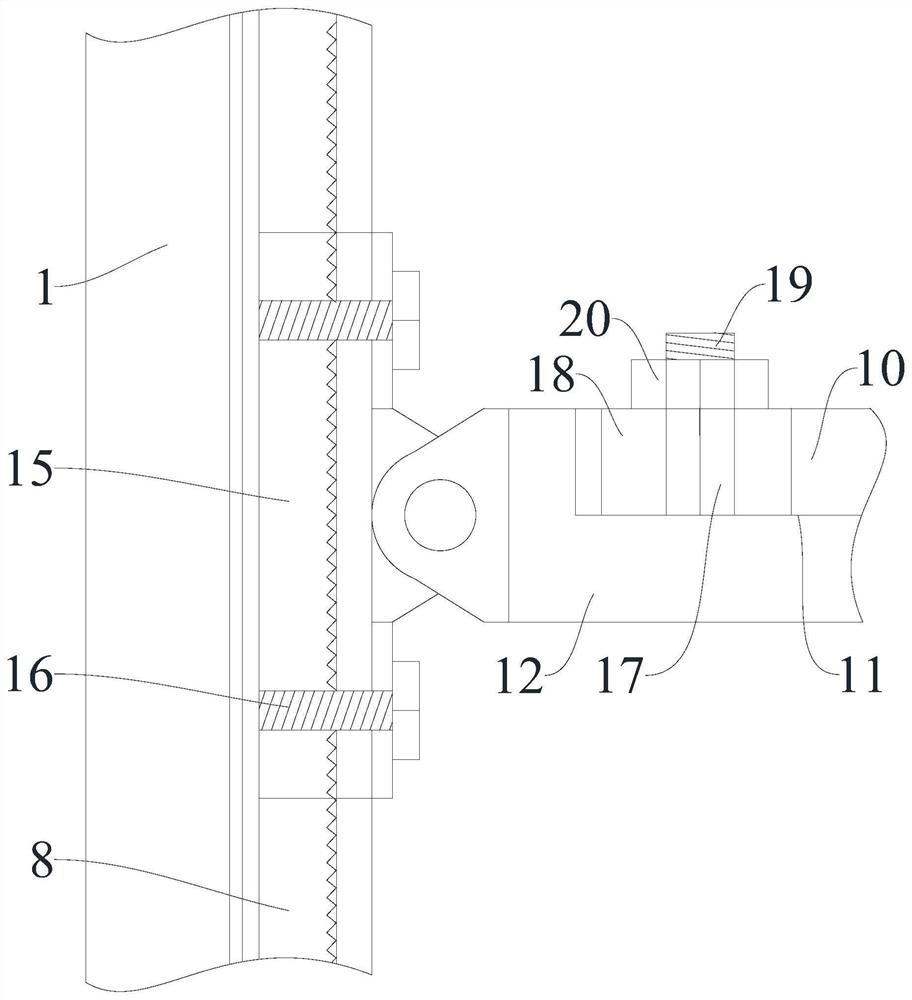

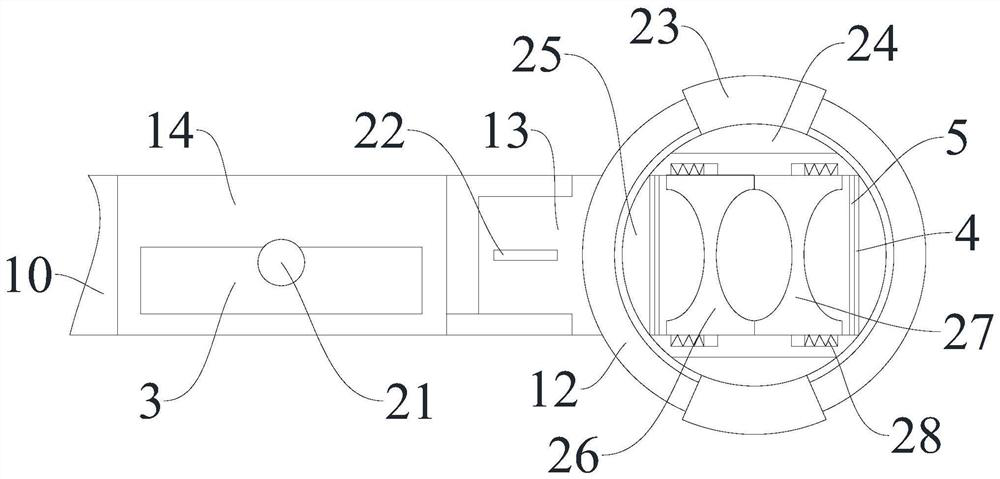

[0023] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0024] figure 1 , figure 2 with image 3 An integrated safety guide mechanism for twisting machine is shown as an integrated safety guide mechanism for twisting machine, including twisting frame 1, bottom drive motor 2, LED status indicator 3, used to control LED status The pressure sensor controller 4 and the temperature sensor controller 5 of the indicator lamp 3, the lower end of the inner side of the twisting frame 1 is welded and fixed with the bottom horizontal mounting plate 6 for installing the bottom driving motor 2, inside the twisting frame 1 The lower end of the side is located above the bottom transverse mounting plate 6 and a transverse support plate 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com