Fuel platform maintenance docking device and docking device control system

A technology of a docking device and a control system, which is applied to bridge parts, bridge forms, bridges, etc., can solve problems such as insufficient platform stability, damage to the moving platform and the docking maintenance device, and difficulty in maintaining the moving platform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

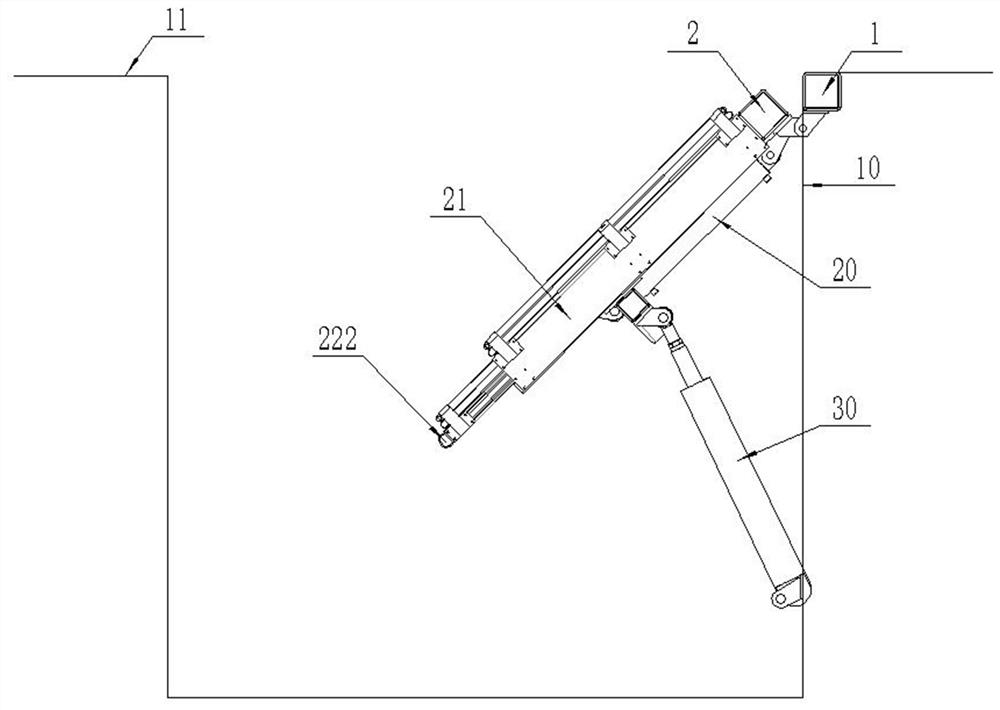

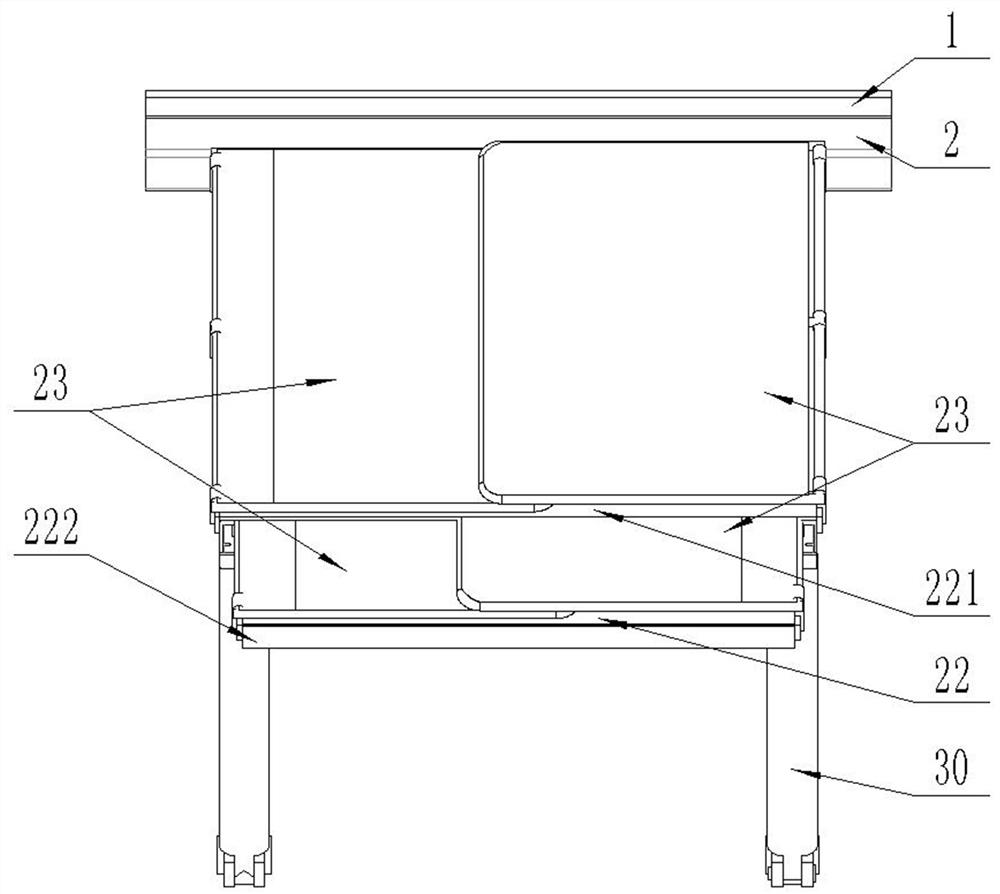

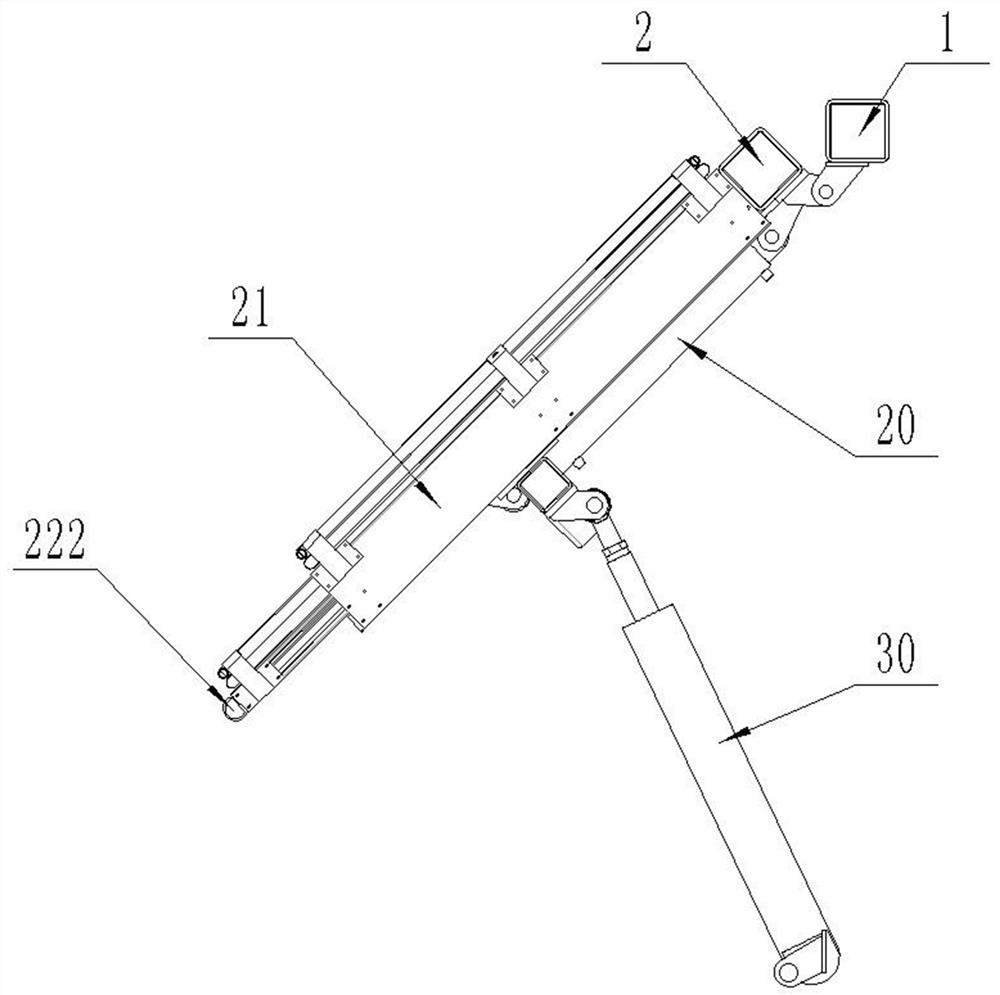

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a fuel oil station maintenance docking device, including:

[0025] The fixed beam 1 fixed in the pit wall 10 can play a good role in supporting and hanging the docking device.

[0026] The first movable beam 2, which is rotatably connected with the fixed beam 1, adopts the joint mode of the hinge seat and the pin shaft, and the rotation effect is better. The middle part of the first movable beam 2 is connected with a telescopic hydraulic cylinder 20, and the telescopic hydraulic cylinder 20 is connected to the telescopic slide plate 22. There is a certain gap to avoid jamming during the telescopic movement. Both sides of the first movable beam 2 are fixedly connected with sliding guide rails 21, and the two sliding guide rails 21 are slidingly connected with telescopic skateboards 22 through several pulleys. 22, to realize the telescopic movement of the telescopic slide plate 22, the other end of the te...

Embodiment 2

[0031] The working principle of the present invention: ①Rotary movement: the docking device is driven by double hydraulic cylinders, and is raised from the storage side hanging and the pit wall 10 around the rotation axis to a position flush with the workshop floor and the test platform 11. ②Telescopic movement: the telescopic slide plate 22 of the docking device is driven by the telescopic hydraulic cylinder 20, and stretches out at a certain speed to dock with the test platform 11. When it is about to approach the test platform 11, the speed slows down, approaches the platform and overlaps the test platform 11 by about 100mm After stop motion, the hydraulic station stops working, and the lifting hydraulic cylinder 30 and the telescopic hydraulic cylinder 20 are locked by the hydraulic balance valve simultaneously, even if the system bursts, there will be no danger. ③ After reaching the set position, unfold and lock the two-stage four-sided guardrail 23 . ④ Anti-collision str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com