A fine-tuning anchor and method capable of compensating for prestress loss in water-rich sand layers

A water-rich sand layer and prestressing technology, which is applied to the installation of bolts, earthwork drilling, drilling automatic control systems, etc., can solve problems such as subsidence and soil extrusion, and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

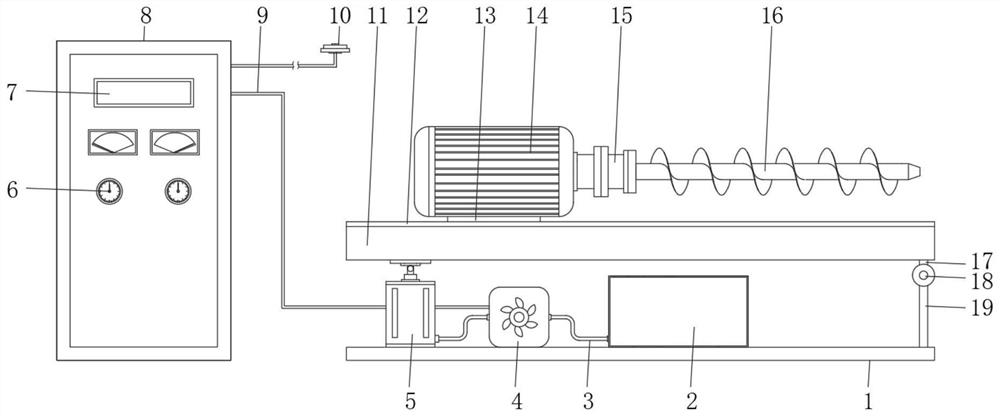

[0028] See figure 1 One embodiment of the present invention: a fine-tuning anchor capable of compensating the prestress loss of the rich sand layer, including the bottom plate 1, the control cabinet 8, the rack 11, the connecting plate 13 and the third connecting rod 24, the bottom plate 1 The upper surface is fixed with a tank 2, and the hydraulic oil is loaded in the tank 2. The upper surface of the bottom plate 1 on one side of the tank 2 is fixed, as is well known to those skilled in the art, and the hydraulic pump 4 power is present, and it is a conventional means or known common sense, and will not be described later in the art. Personnel can make any optional or convenient. The upper surface of the upper surface of the hydraulic pump 4 is fixed to the upper surface of the hydraulic cylinder 5, and the plurality of hydraulic rod 22 is attached to the top end of the hydraulic cylinder 5, and the top end of the multi-stage hydraulic rod 22 is rotated at one end of the third co...

Embodiment 2

[0030] See figure 1 , Figure 4 and Figure 5One embodiment of the present invention is: a fine-tuning anchor capable of compensating for the prestress loss of the rich sand layer, the liquid pressure pump 4 is in communication with the tank 3, and the hydraulic pump 4 is passed through the tubing 3 Connect with the hydraulic cylinder 5, the hydraulic pump 4 transmits the hydraulic oil in the tank 2 through the tubing 3 to the hydraulic cylinder 5, and the hydraulic cylinder 5 pushes the multi-stage hydraulic rod 22 by the hydraulic oil. The hydraulic pump 4 causes the hydraulic oil in the hydraulic cylinder 5 in the hydraulic cylinder 5 to drive the multi-stage hydraulic rod 22 downward by the oil pipe 3. The front and rear ends of the other side of the rack 11 are fixed, and the first connecting rod 17 is fixed, and the bottom end of the two first connecting rods 17 is rotated by the first axis 18, and two seconds. The connecting rod 19 is fixed to the front and rear ends of the b...

Embodiment 3

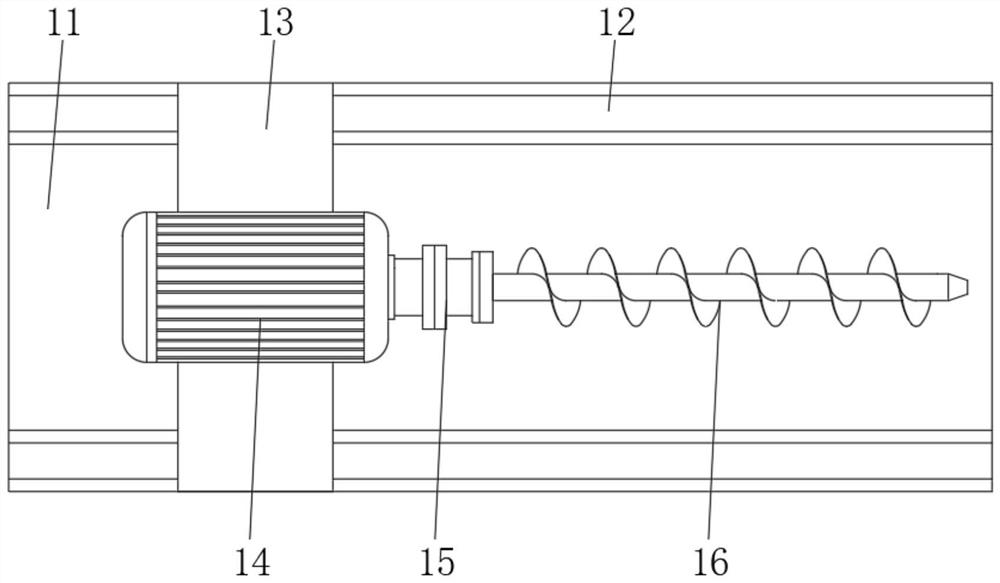

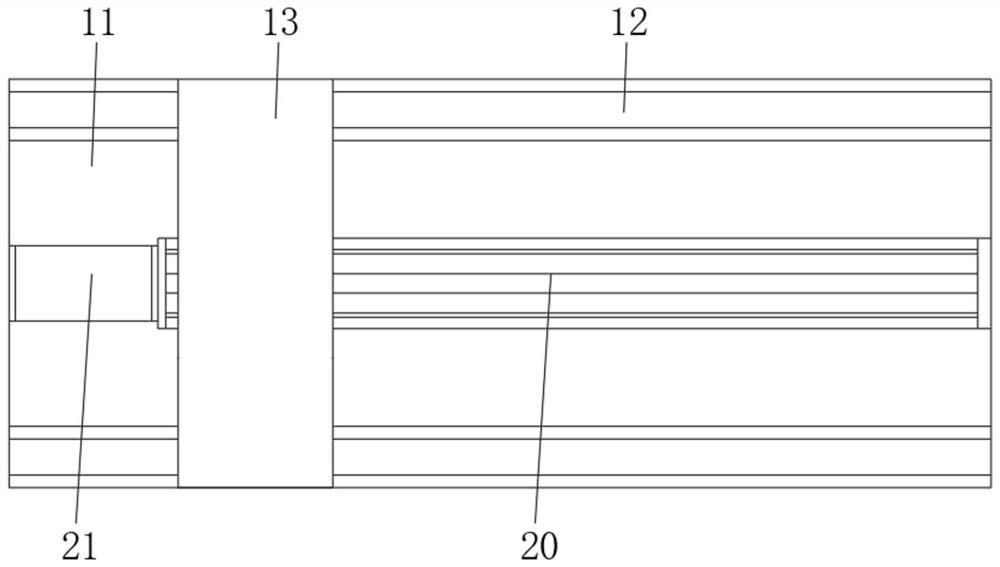

[0032] See figure 2 and image 3 One embodiment of the present invention is provided that a thin-tuning anchor capable of compensating for the prestress loss of the rich sand layer, and a screw 20 is fixed in the middle of the groove on the upper surface of the frame 11, and the rack 11 of the lead screw 20 The surface is fixed having a stepper motor 21, and the step motor 21 is rotatable with the screw 20, and the intermediate of the lower surface of the connecting plate 13 is attached to the lead screw 20, and the upper surface of the connecting plate 13 is fixed to the motor 14, the motor 14 One end is rotated by the drive shaft 15 with an anchor 16. The stepper motor 21 is powered on, and the motor 14 on the connecting plate 13 is moved by the screw 20, and the anchor 16 of the motor 14 is moved to the soil layer. The lead screw 20 can drive the connecting plate 13 to reciprocate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com