Hydraulic support frame

A technology of hydraulic supports and hydraulic cylinders, which is applied in mine roof supports, safety devices, mining equipment, etc., can solve problems such as low scope of application, danger, and large amounts of dust, so as to improve dust suppression efficiency, increase contact area, and protect surrounding areas. The effect of area increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

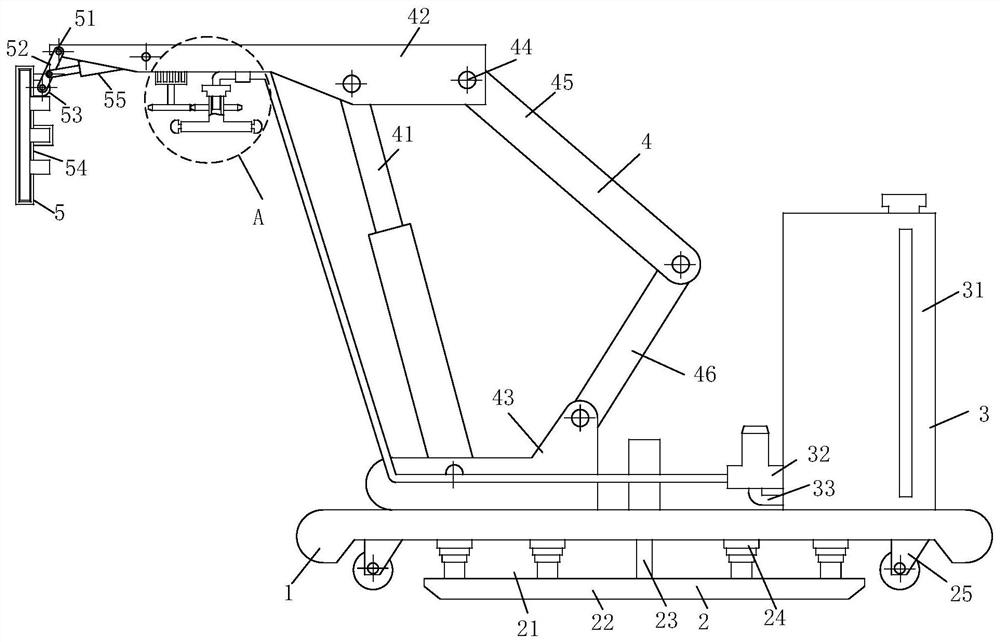

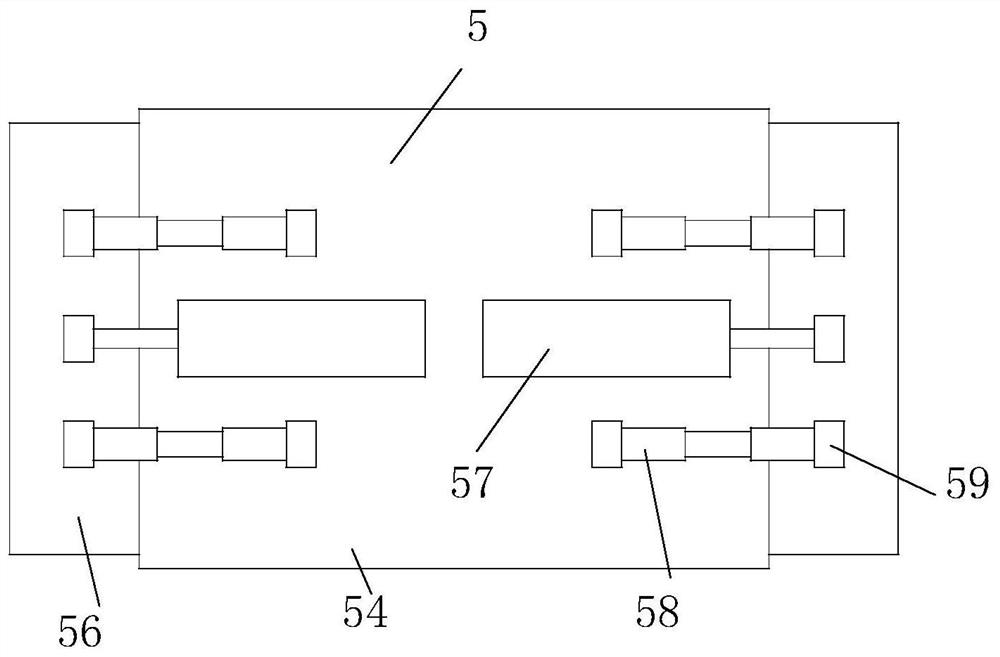

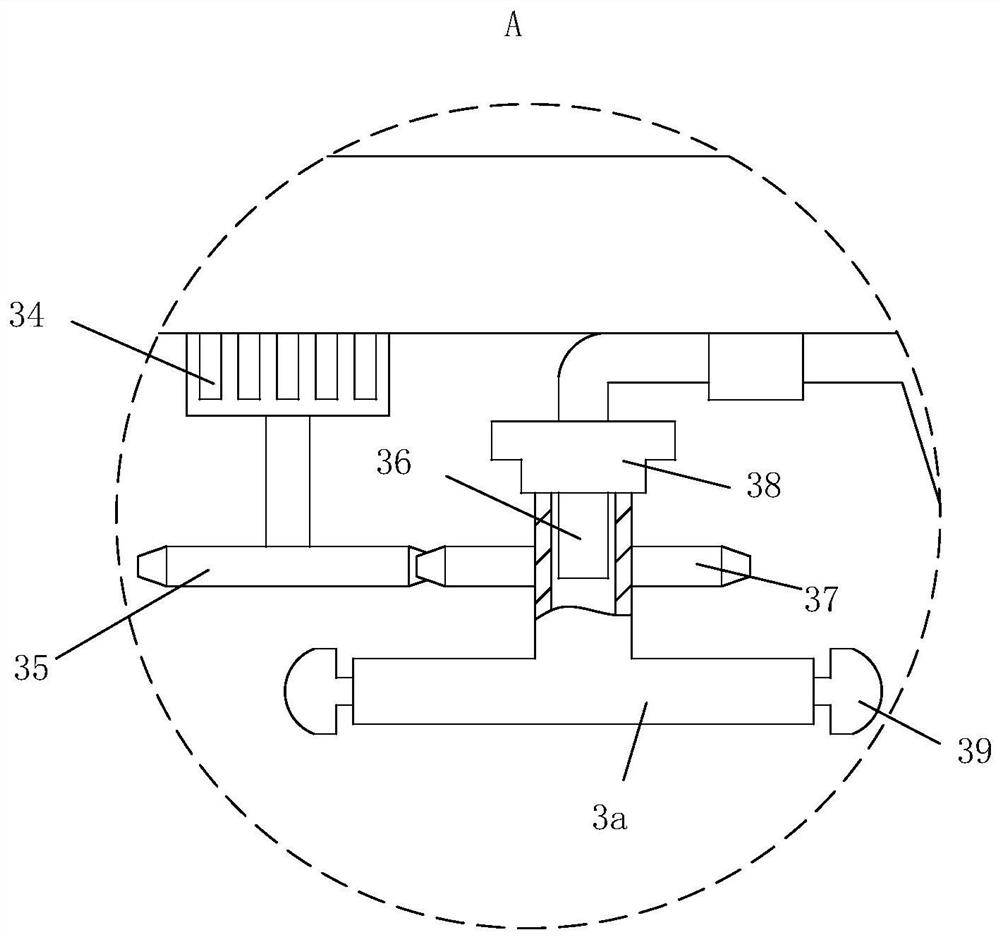

[0020] Please refer to Figure 1-4 As shown, a hydraulic support includes a base 1, a supporting mobile structure 2, a rotating spraying dust suppression structure 3, a lifting support structure 4 and an adjusting support structure 5; the adjusting support mechanism 5 is connected to the rotating spraying dust suppression structure 3, and The adjustment support structure 5 is connected to the lifting support structure 4, and the adjustment support structure 5 includes a second pin shaft 51, a swing rod 52, a support plate 53, a front beam frame 54, a third hydraulic cylinder 55, an extension plate 56, and a fourth hydraulic pressure cylinder. Cylinder 57, spacer 58 and second telescopic sleeve 59, front beam frame 54 are installed on lifting support structure 4 top, front beam frame 54 top rear side is connected with support plate 53, and support plate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap