Coiled tube type loop heat pipe

A loop heat pipe and coil type technology, applied in the field of heat pipes, can solve problems such as failure to save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

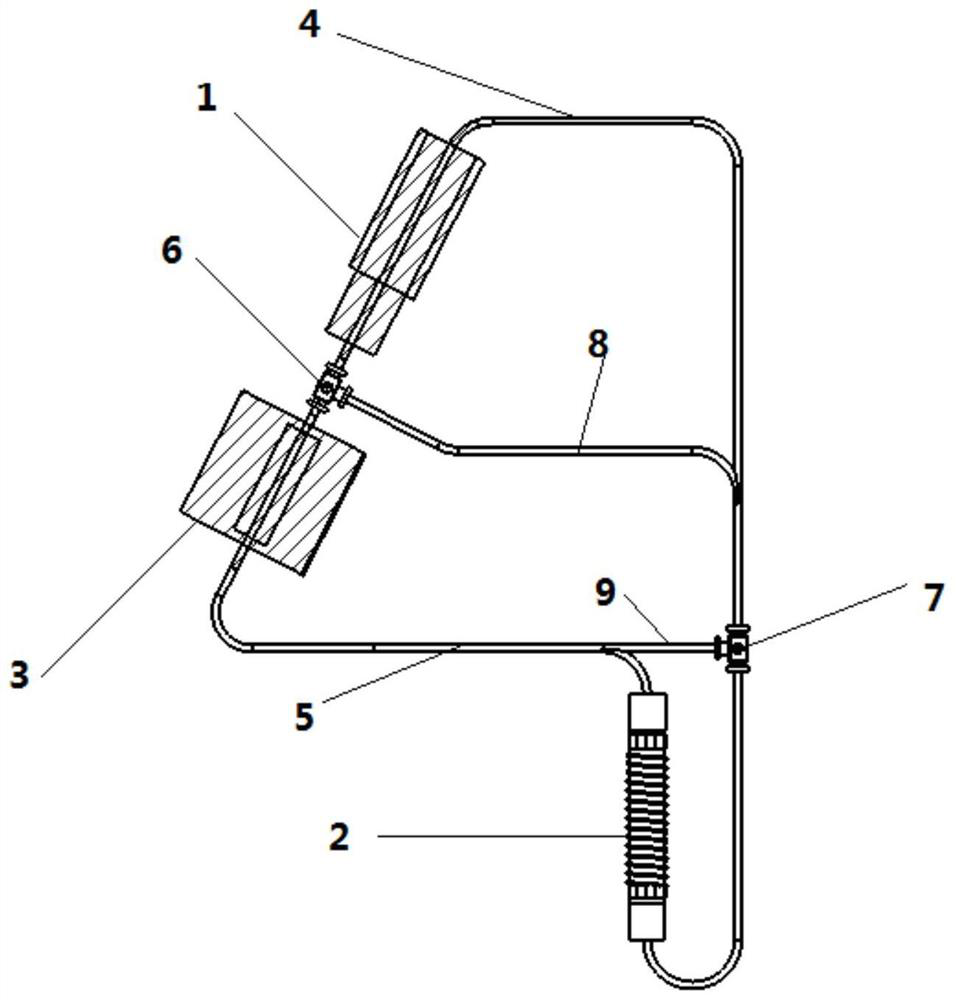

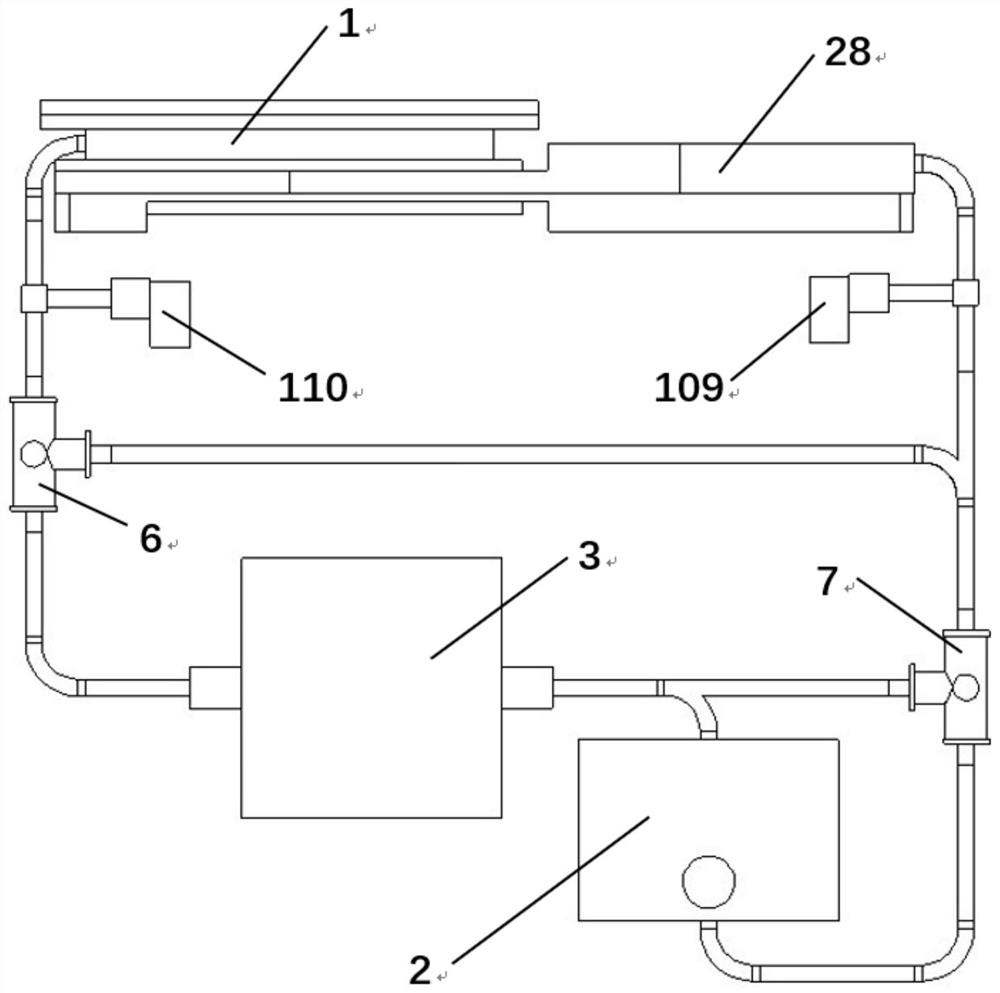

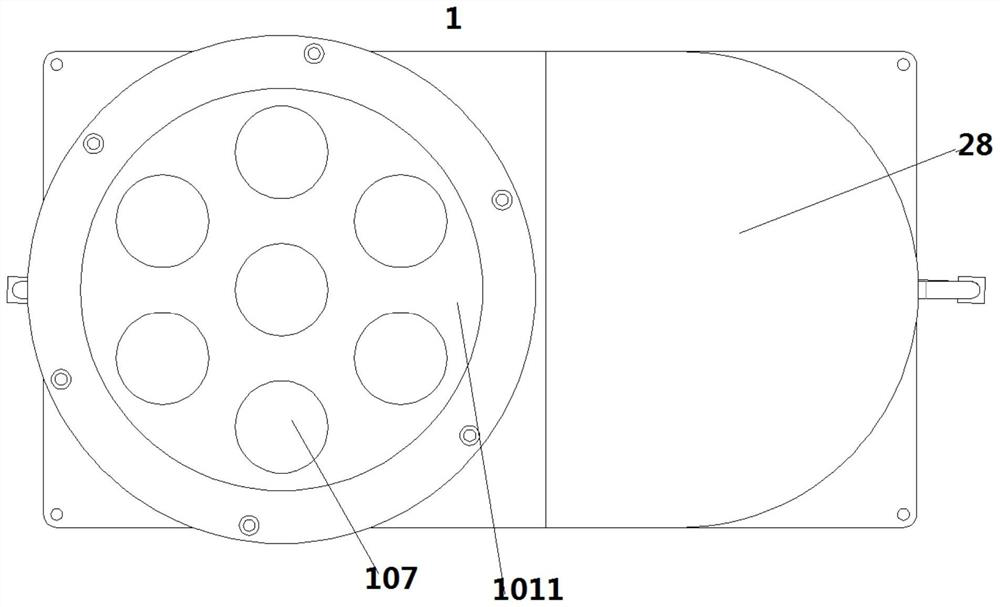

[0046] like figure 1 As shown, a loop heat pipe includes an evaporator 1, a condenser 2 and a heat accumulator 3, and the evaporator 1 and the condenser 2 form a circulation pipeline through a first pipeline 4 and a second pipeline 5, so The fluid absorbs heat and evaporates in the evaporator, then enters the condenser 2 to release heat through the first pipeline 5, and then circulates the fluid from the condenser 2 back to the evaporator 1 through the second pipeline 5, and the heat accumulator 3 Set in the second line. By setting the heat accumulator, excess heat can be stored in the heat accumulator, so as to better realize the utilization of heat.

[0047] Preferably, the heat pipe further includes a first three-way valve 7 and a second three-way valve 6, the first three-way valve 7 is set on the first pipeline 4, and the second three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com