A light interference linear oil film thickness detection method for thrust ball bearings

A thrust ball bearing, oil film thickness technology, applied in the field of testing, can solve the problem of inability to accurately reflect the oil film thickness state, etc., to achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings.

[0035] A thickness detection method of a thrust ball bearing optical interference linear oil film, as follows:

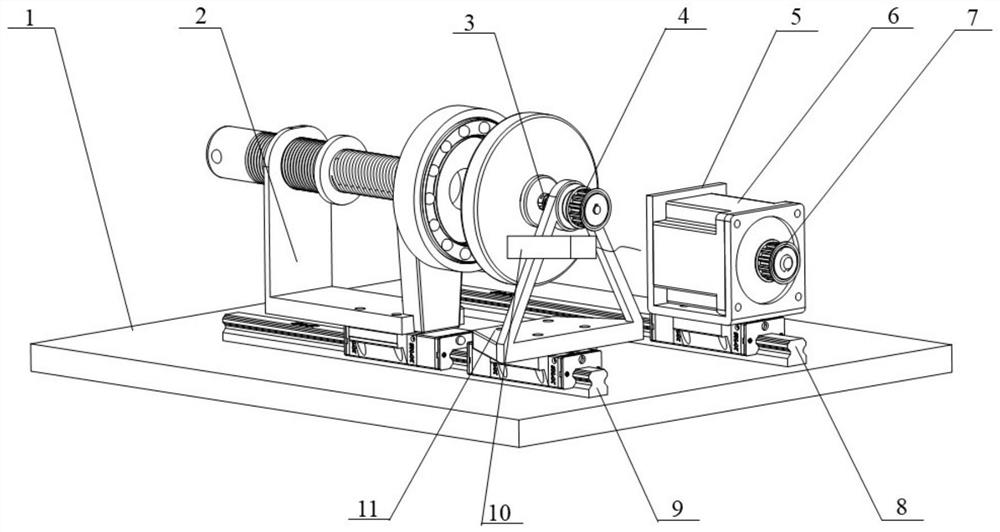

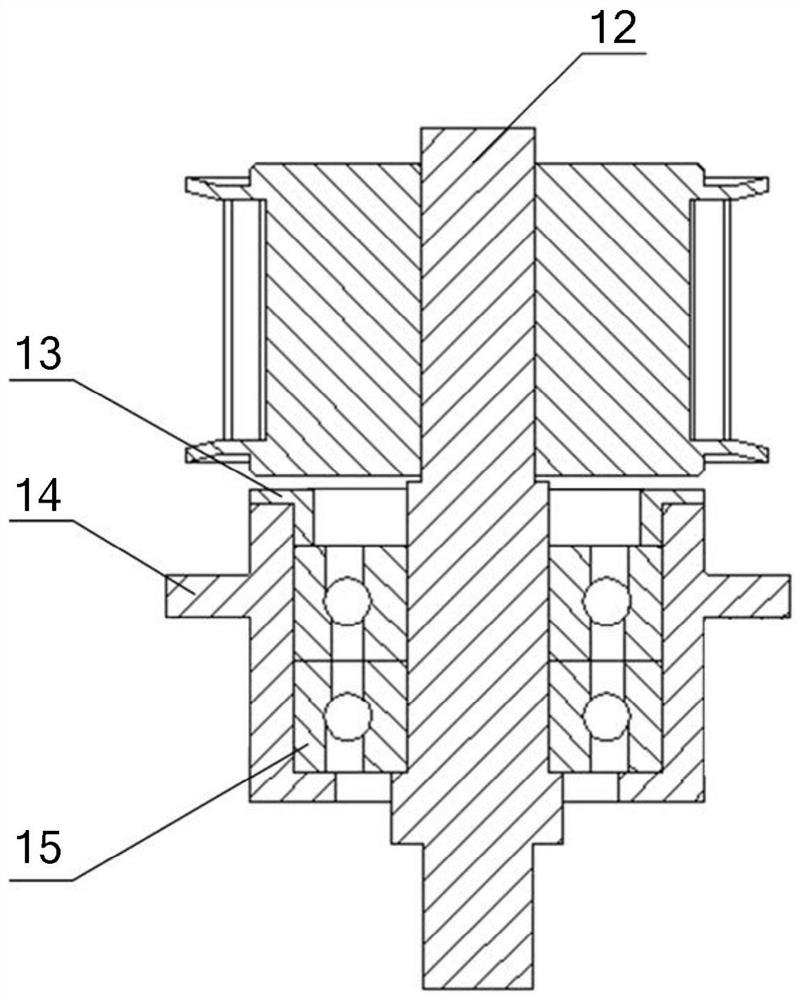

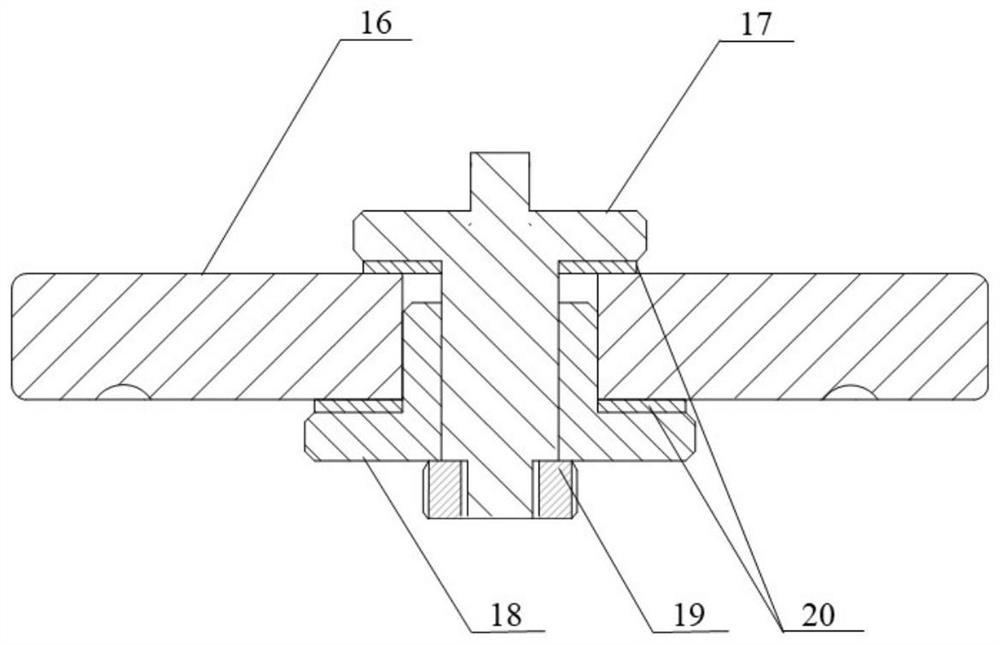

[0036] Step 1, such as figure 1 and 2 As shown, the transmission module support rail 9 provided horizontally disposed is fixed to the test stage base 1, and the transmission module bracket 11 is constituting the sliding deputy; then, the fastening bolt is opened through the drive module holder. The through hole and the transmission module support the adjustment slot of the slide, together with the nut, and realize the transmission module holder to support the drive module support slide rail; then, the drive shaft 12 is supported from the bearing angle contact ball bearing 15 14 Inside 14; the bearing gasket 13 and the bearing jacket are fixed by screws, and the double-row angle contact ball bearing is axial limit; finally, the bearing outer casing 14 and the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com