Vibration type magnetic field detection device

A detection device and vibration technology, which is applied in the direction of the magnitude/direction of the magnetic field, can solve complex and high-cost problems, and achieve the effect of simple device, low cost and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

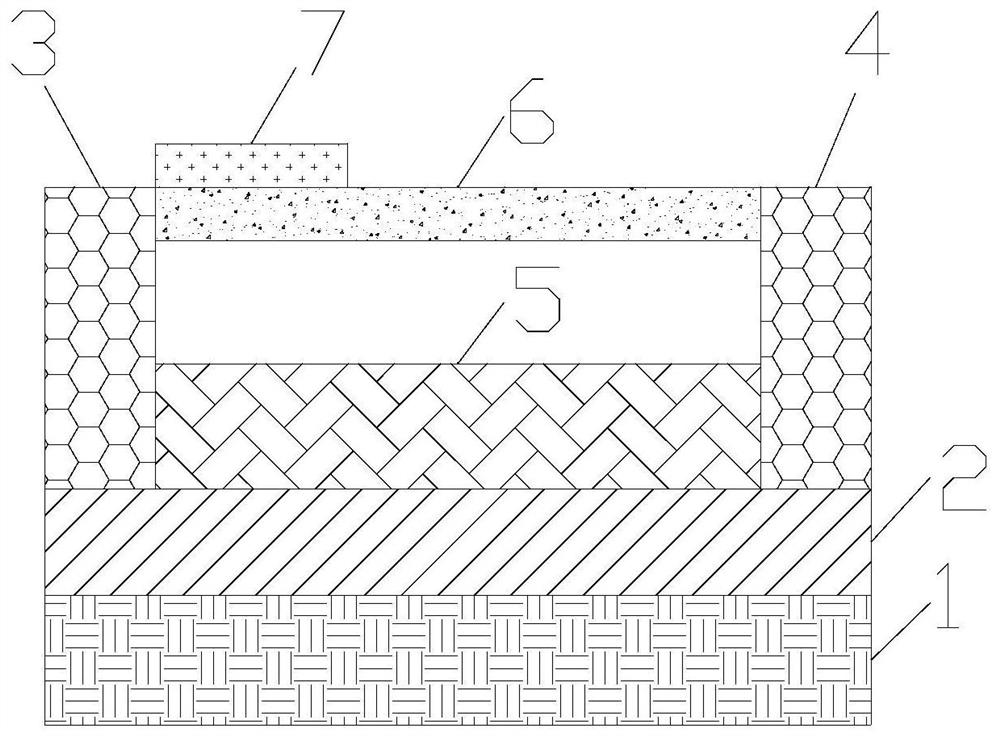

[0020] The invention provides a vibration type magnetic field detection device. Such as figure 1 As shown, the magnetic field detection device includes a vibration source 1 , an elastic layer 2 , a first fixing part 3 , a second fixing part 4 , a magnetostrictive part 5 , a vibration structure part 6 , and a piezoelectric material block 7 . The elastic layer 2 is placed on the vibration source 1 . The material of the elastic layer 2 is rubber, polyester material or acrylic material. Vibration source 1 is broadband. The magnetostrictive part 5 , the first fixing part 3 and the second fixing part 4 are placed on the elastic layer 2 . In practical applications, the first fixed part 3 and the second fixed part 4 can also go deep into the elastic layer 2, but the first fixed part 3 and the second fixed part 4 are not connected to the vibration source 1, so that the first fixed part 3 and the second fixed part 4 are not connected to the vibration source 1. The connection between...

Embodiment 2

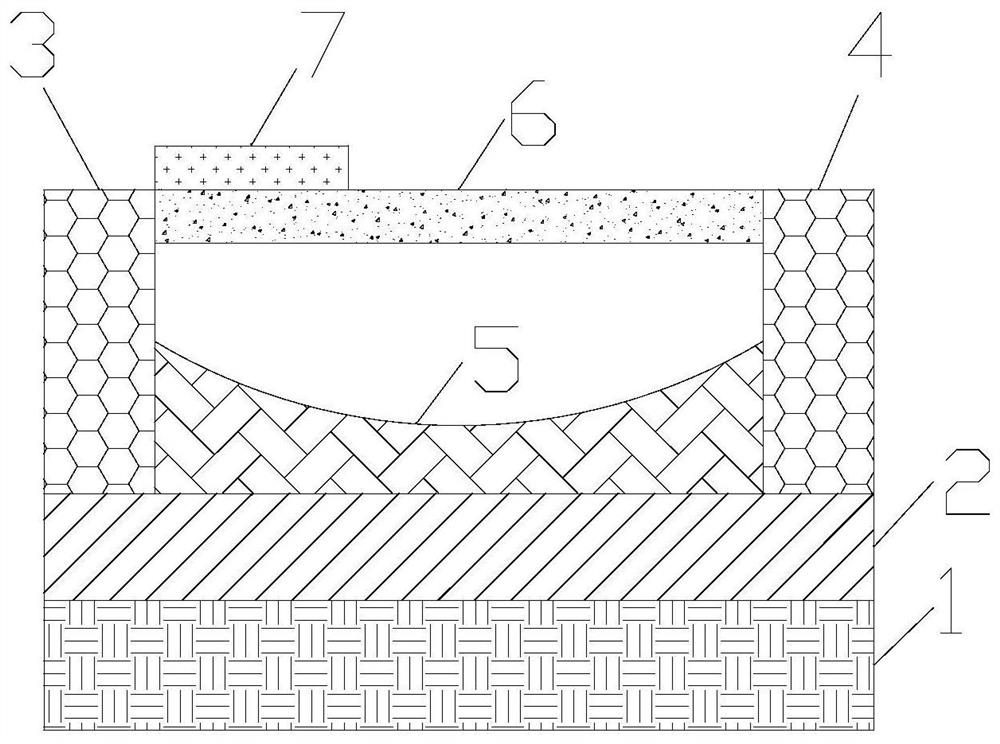

[0024] On the basis of Example 1, such as figure 2 As shown, the upper surface of the magnetostrictive part 5 is concave. In this way, more vibration space is left for the vibration structure part 5 . The following problems have been successfully solved: the magnetostrictive part 5 needs to be high so that the magnetostrictive part 5 can provide greater power to push the first fixed part 3 and the second fixed part 4 to separate, thereby increasing the vibration force in the vibrating structure part 6. Stress changes; however, when the magnetostrictive portion 5 is high, the vibrating structure portion 6 lacks a space for vibration. Because the vibration of the vibrating structure part 6 is strongest in the middle of the vibrating structure part 6, the upper surface of the magnetostrictive part 5 is set in a concave shape in this embodiment, which successfully solves the above-mentioned problem.

Embodiment 3

[0026] On the basis of the second embodiment, the vibrating structure part 6 is provided with through holes. The holes reduce the material consumption of the vibrating structure part 6. When a pulling force is applied at both ends of the vibrating structure part 6, more and more concentrated stresses are generated in the vibrating structure part 6, so that the natural vibration frequency of the vibrating structure part 6 changes more , which improves the sensitivity of magnetic field detection.

[0027] Furthermore, the holes are round or square for ease of preparation. On the contrary, if the holes are made into other special shapes, the requirements for the etching process are high.

[0028] Furthermore, the holes are strip-shaped. The direction of the bar is along the direction of the line connecting the first fixing part 3 and the second fixing part 4 . In this way, when tension is applied to both ends of the vibrating structure part 6, the distribution of the stress is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com