High-sensitivity vibration type magnetic field detection device

A detection device, vibrating technology, applied in the direction of the size/direction of the magnetic field, which can solve the problems of complexity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

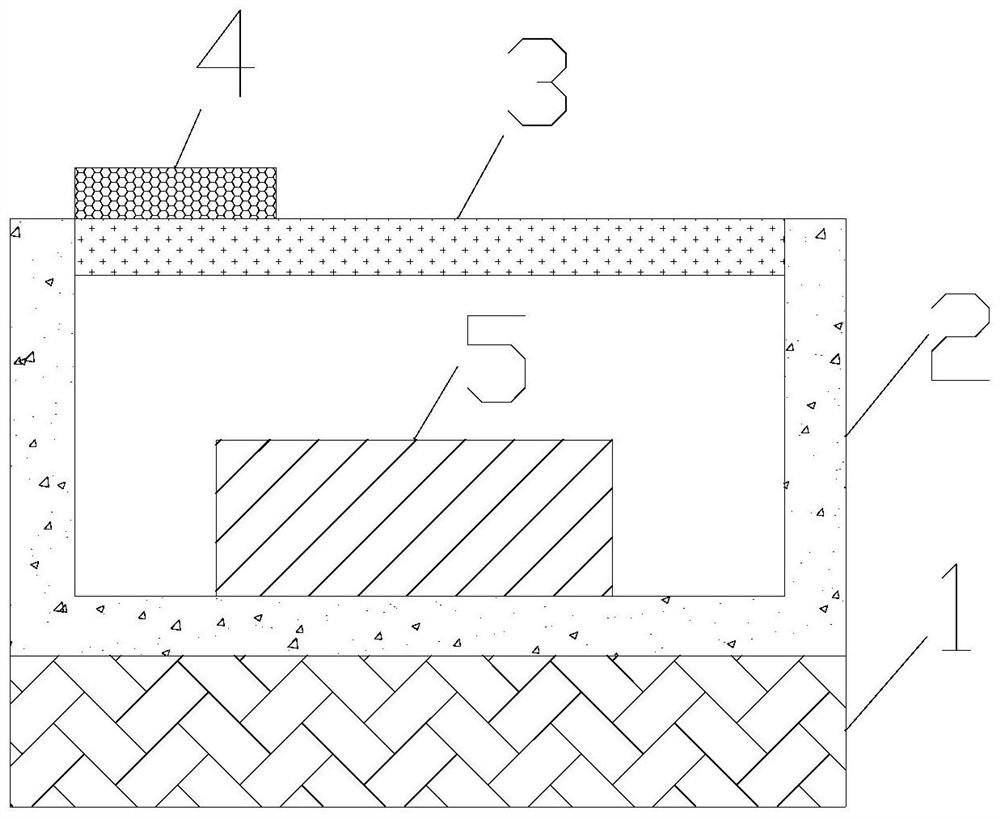

[0021] The invention provides a high-sensitivity vibration type magnetic field detection device. Such as figure 1 As shown, the magnetic field detection device includes a vibration source 1 , a wall 2 , a vibration structure part 3 , a piezoelectric material block 4 , and a magnetostrictive block 5 . The device wall 2 and the vibrating structure part 3 are fixedly connected, and the device wall 2 and the vibrating structure part 3 enclose a closed cavity. The material of the vibrating structure part 3 is aluminum alloy, silicon, semiconductor material, diamond. The bottom of the wall 2 is placed on the vibration source 1, and the vibration source 1 is broadband and provides vibration with a certain frequency range. The piezoelectric material block 4 is placed on the edge of the vibrating structure part 3 , and the piezoelectric material block 4 is connected to an external circuit for monitoring the vibration of the vibrating structure part 3 . The piezoelectric material blo...

Embodiment 2

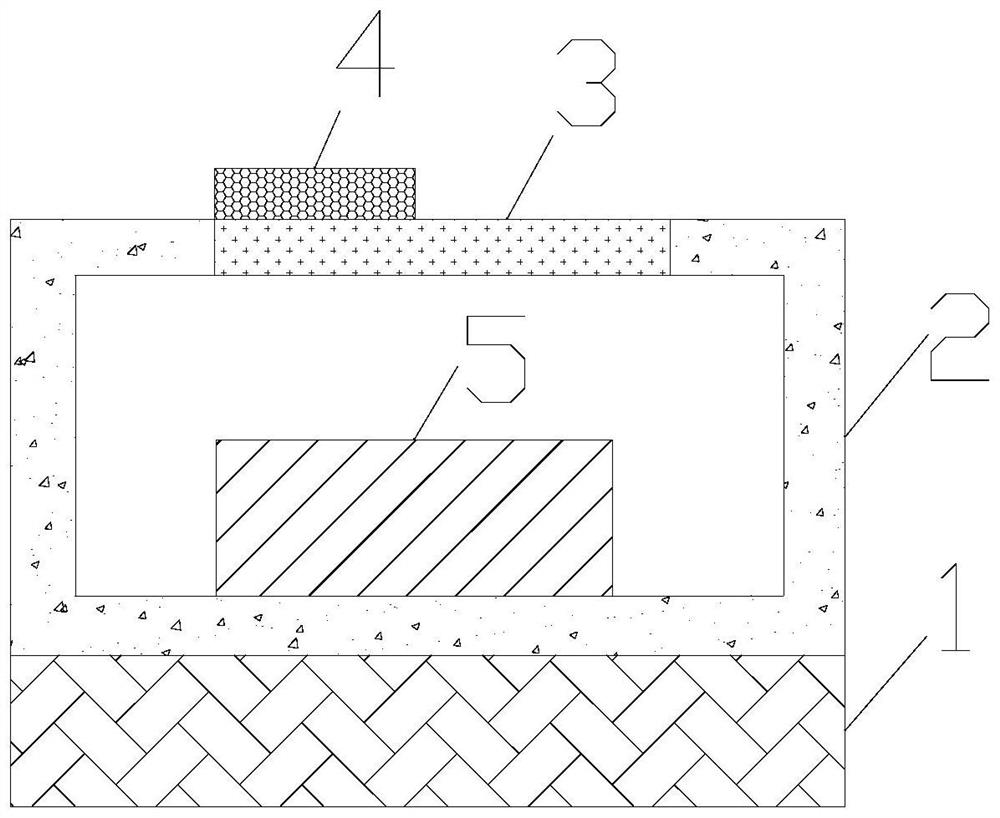

[0028] On the basis of Example 1, such as figure 2 As shown, the cavity is a cuboid. The area of the vibration structure part 3 is smaller than the area of the top surface of the cuboid. That is to say, compared with the vibration structure part 3 on the top surface of the cuboid, the size of the vibration structure part 3 is reduced in this embodiment. In this way, the size of the cavity can be set large, but the size of the vibrating structure part 3 is still small. In this way, the volume of the magnetostrictive block 5 in the cavity can be increased a lot, and these volume increases are reflected in the deformation of the small-sized vibrating structure part 3 . In this way, the stress in the vibrating structure part 3 is changed more, the natural frequency of the vibrating structure part 3 is changed more, and the sensitivity of magnetic field detection is improved.

Embodiment 3

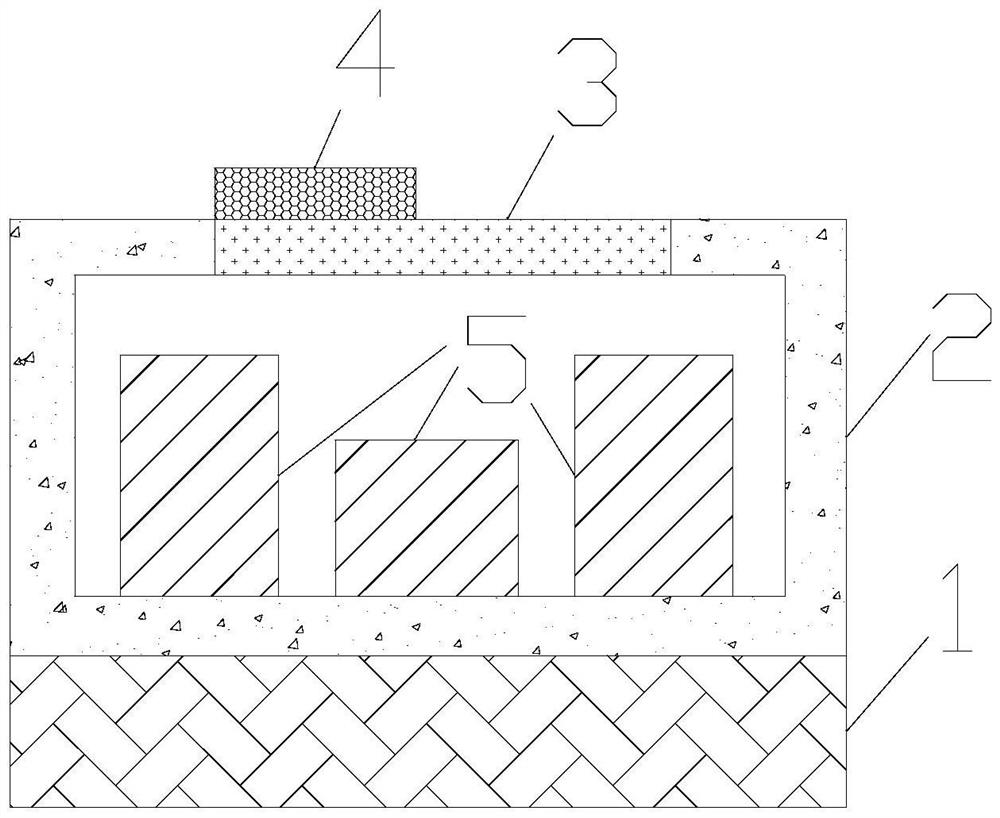

[0030] On the basis of Example 2, such as image 3 As shown, the number of magnetostrictive blocks is more than one. The characteristic directions of the magnetostrictive blocks 5 are different. Under the action of magnetic fields in different directions, different magnetostrictive blocks 5 can all be elongated, so that magnetic fields in different directions can be detected. In addition, the volume in the cavity is also fully utilized to place more magnetostrictive blocks 5 . Under the action of the magnetic field to be measured, the pressure in the cavity changes more, which improves the sensitivity of magnetic field detection.

[0031] Further, as image 3 As shown, in the middle of the cavity, the height of the magnetostrictive block 5 is smaller than the height of the magnetostrictive block 5 at the edge of the cavity. The vibrating structure part 3 is arranged at the center of the top surface of the cuboid. In this way, a space for vibration is reserved for the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com