Wide-range magnetic field detection device

A detection device and wide-range technology, which is applied in the direction of the size/direction of the magnetic field, can solve the problems of narrow magnetic field detection range, complex device, high cost, etc., and achieve the effect of wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

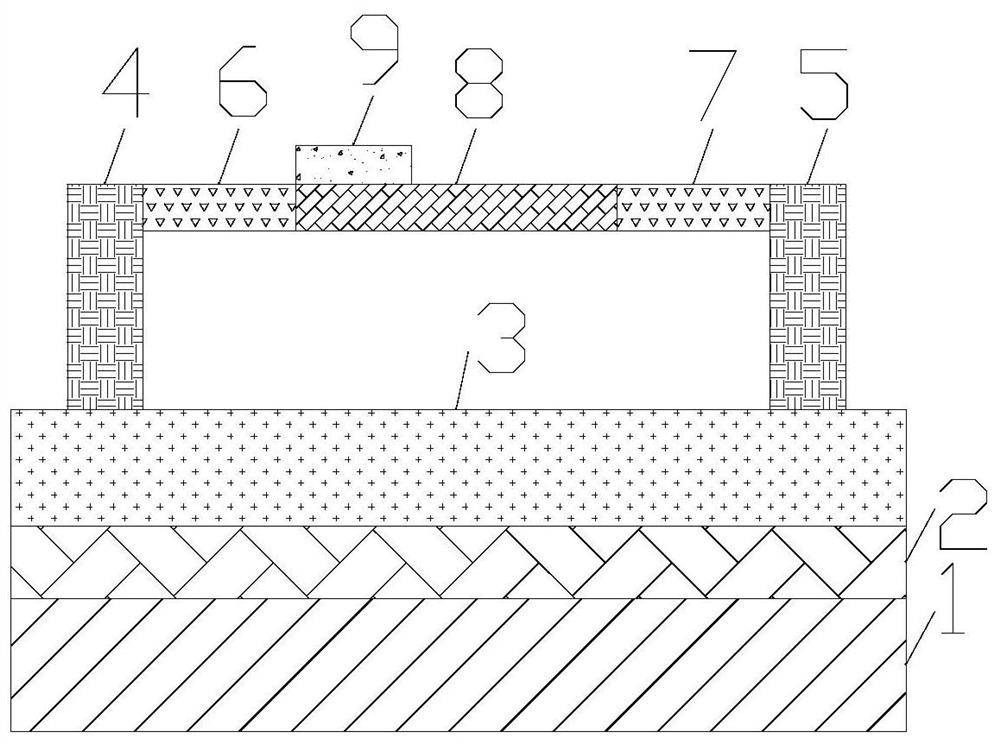

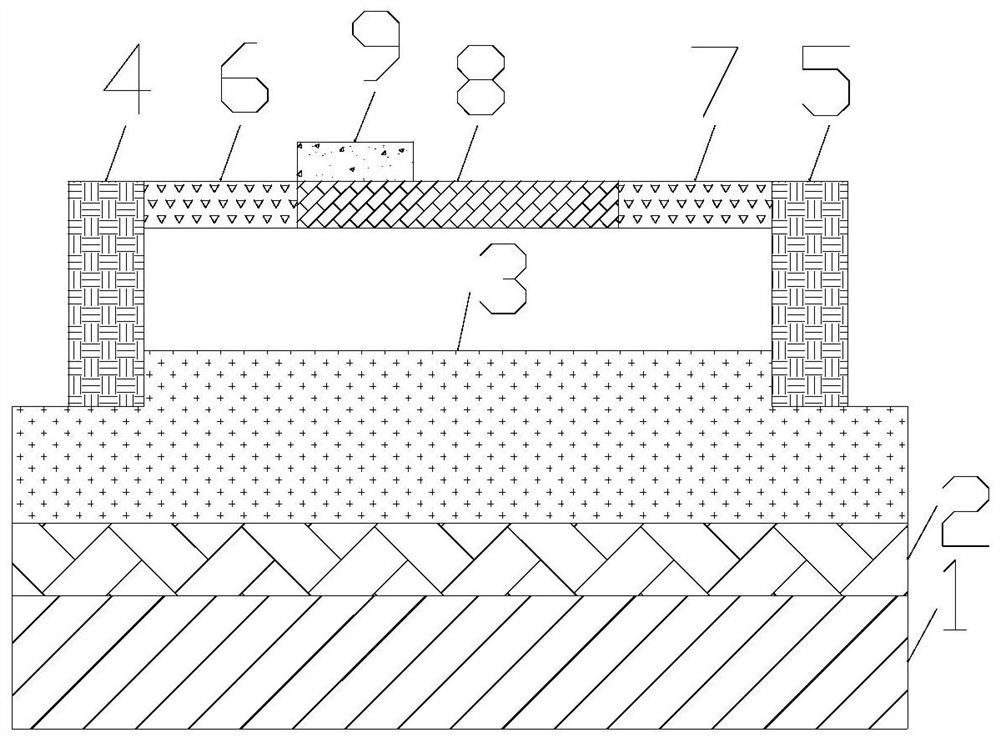

[0020] The invention provides a wide range magnetic field detection device. Such as figure 1 As shown, the magnetic field detection device includes a vibration source 1, an elastic layer 2, a magnetostrictive layer 3, a first fixed part 4, a second fixed part 5, a first connecting part 6, a second connecting part 7, and a vibration structure part 8 , Piezoelectric material block 9 . The elastic layer 2 is placed on the vibration source 1 . The vibration source 1 is broadband and can provide mechanical vibration in a certain frequency range. The material of the elastic layer 2 is rubber, polyester material or acrylic material. The magnetostrictive layer 3 is placed on the elastic layer 2 . Both ends of the vibration structure part 8 are fixedly connected to one end of the first connection part 6 and the second connection part 7 respectively, and the material of the vibration structure part 8 is aluminum alloy, silicon, semiconductor material, diamond. The other ends of the...

Embodiment 2

[0023] On the basis of Embodiment 1, screws are also included, and the screws are used to control the connection angles of the first connecting part 6 and the second connecting part 7 with the first fixing part 4 and the second fixing part 5 respectively. One screw passes through the connecting portion of the first connecting portion 6 and the first fixing portion 4 , and the other screw passes through the connecting portion of the second connecting portion 7 and the second fixing portion 5 . By tightening the screws, the relative angle between the first connecting portion 6 and the first fixing portion 4 and the relative angle between the second connecting portion 7 and the second fixing portion 5 are fixed. When the above angle is changed, the vibrating structure part 8 is elongated or compressed, thereby changing the stress in the vibrating structure part 8 and changing the natural frequency of vibration in the vibrating structure part 8 . The method for adjusting the inter...

Embodiment 3

[0025] On the basis of Embodiment 1, it also includes a force application part, which connects the first connection part 6 or the second connection part 7 to apply an external force in a direction perpendicular to the first connection part 6 or the second connection part 7 . through the figure 1 The external force is applied in the vertical direction, so that the first connecting part 6 or the second connecting part 7 is tilted, thereby stretching the vibrating structure part 8, thereby changing the stress in the vibrating structure part 8, thereby changing the force in the vibrating structure part 8 natural frequency of vibration. In this embodiment, the method for adjusting the internal stress of the vibrating structure part 8 is simple and easy to control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com