OPGW optical cable splice closure fixing device

A technology for optical cable splicing and fixing devices, which is applied in the field of electric power communication, and can solve problems such as fiber core breakage, fiber core easy to swing, and affecting the quality and efficiency of optical cable fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

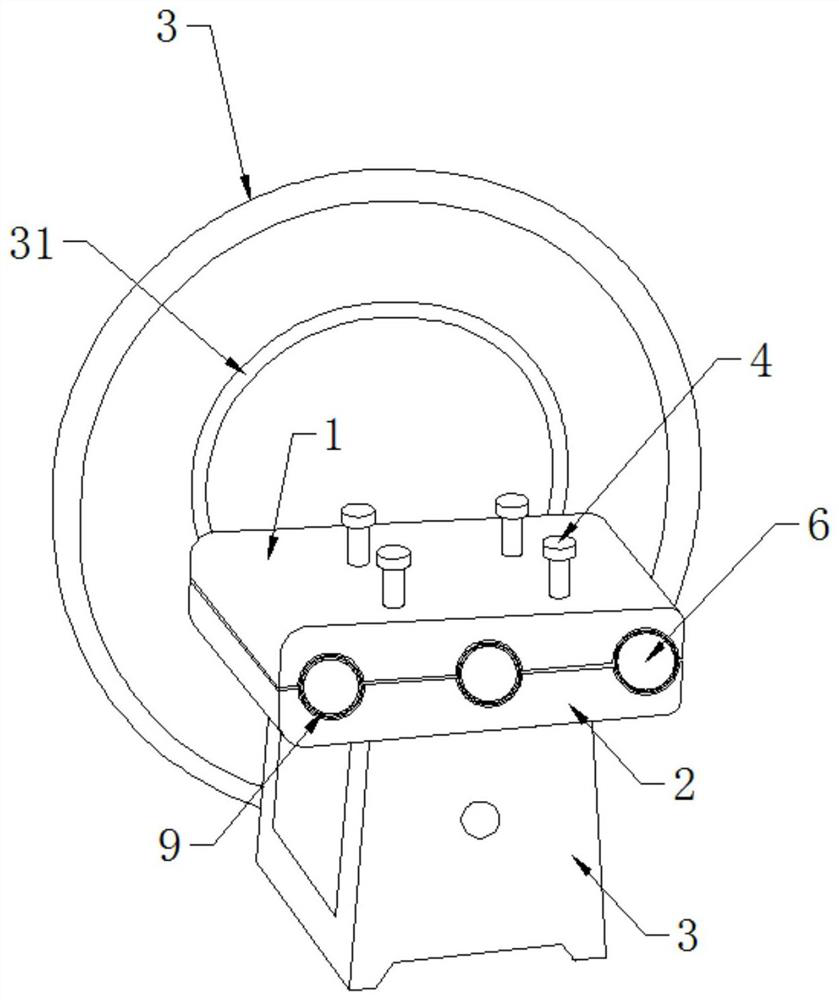

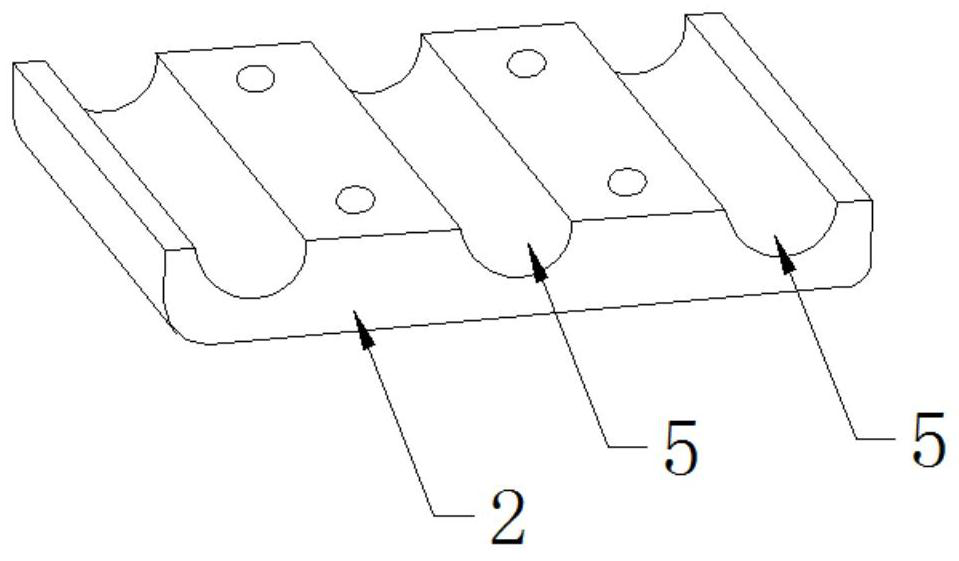

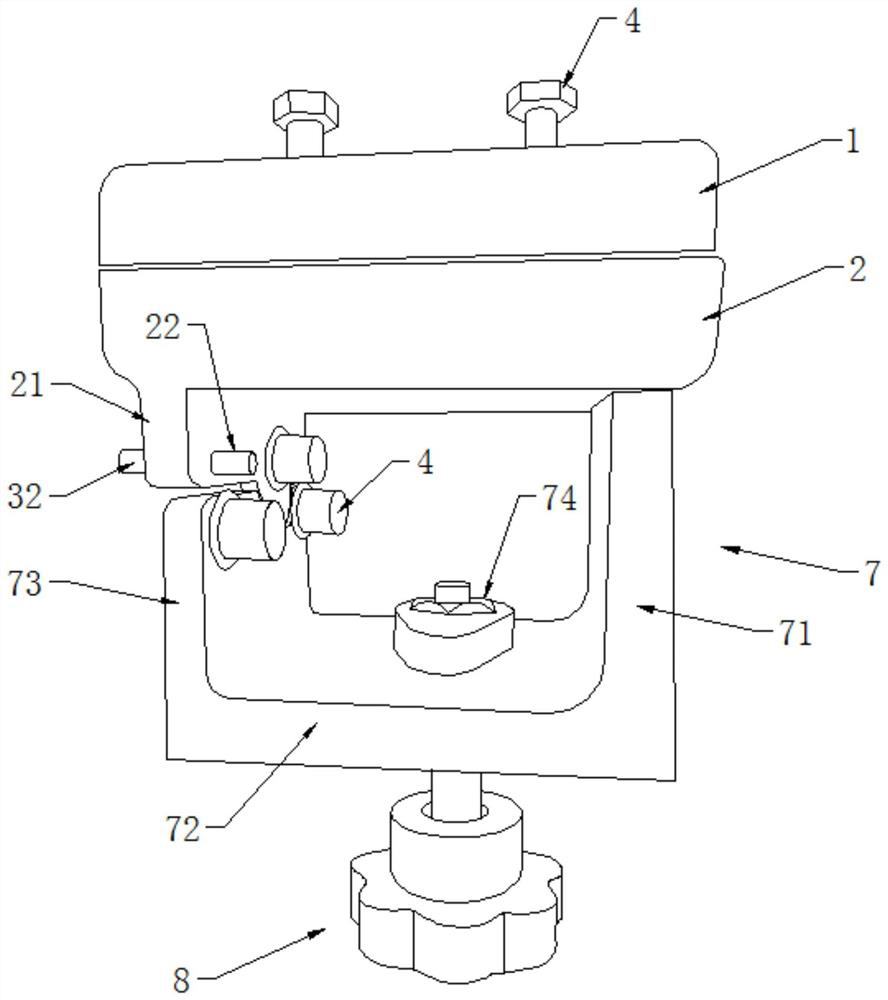

[0028] see Figure 1 to Figure 7 , an OPGW optical cable splicing box, including an upper box 1, a lower box 2 and a disk 3 for clamping and fixing the optical cable, and the upper box 1 and the lower box 2 are connected to the disk 3 after being locked by several bolts 4; The two inner surfaces where the upper box 1 and the lower box 2 are docked are provided with a number of concave half-hole grooves 5, and the corresponding upper and lower half-hole grooves 5 are docked to form a through hole 6 for the optical cable to pass through, and the disc 3 There are also several holes 33 for optical cables to pass through, and the optical cables to be connected pass through the disc 3 and the through hole 6 in turn; the lower surface of the lower box 2 extends vertically downwards to form the first connecting plate 21; The lower surface of the lower box 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com