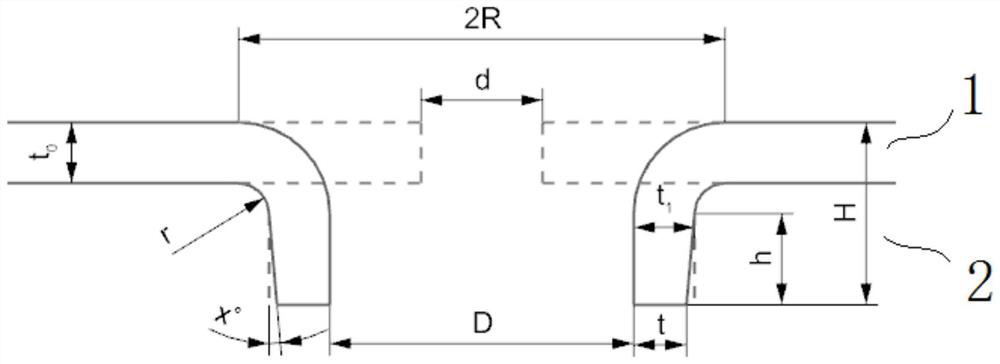

Hole flanging female die, manufacturing method thereof, storage medium and CNC machine tool

A manufacturing method and hole-turning technology, which can be used in simulators, program control, computer control, etc., can solve the problems of shortening the life of the mold, curling of the turning holes, and reducing the strength of the turning holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Present embodiment is CAD platform with UG software, uses VS2015 (internal compiler is Microsoft Visualstudio 2010) integrated environment, under Windows operating system, UG function and NXOpenC++ library are compiled and generated DLL (dynamic link library) by VS2015, for UG After the software is called, the codes for controlling the machining of the CNC machine tool are generated and input into the CNC machine tool to control the machining of the CNC machine tool. Among the above, the full name of UG software is Unigraphics NX, which is an interactive CAD / CAM / CAE / PDM (computer-aided design, aided manufacturing, aided Engineering, product data management) software system, which is often used in the design, processing, simulation and NC code generation of hardware parts, where the NC code can be input into the CNC machine tool to control it for part processing.

[0027] The 3D drawings referred to in this embodiment are all standard 3D drawings in the hardware manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com