a rotary compressor

A technology of rotating compressors and bodies, applied in the field of air-conditioning compressors, which can solve problems such as wear at the lower end of the eccentric part of the crankshaft, and achieve the effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

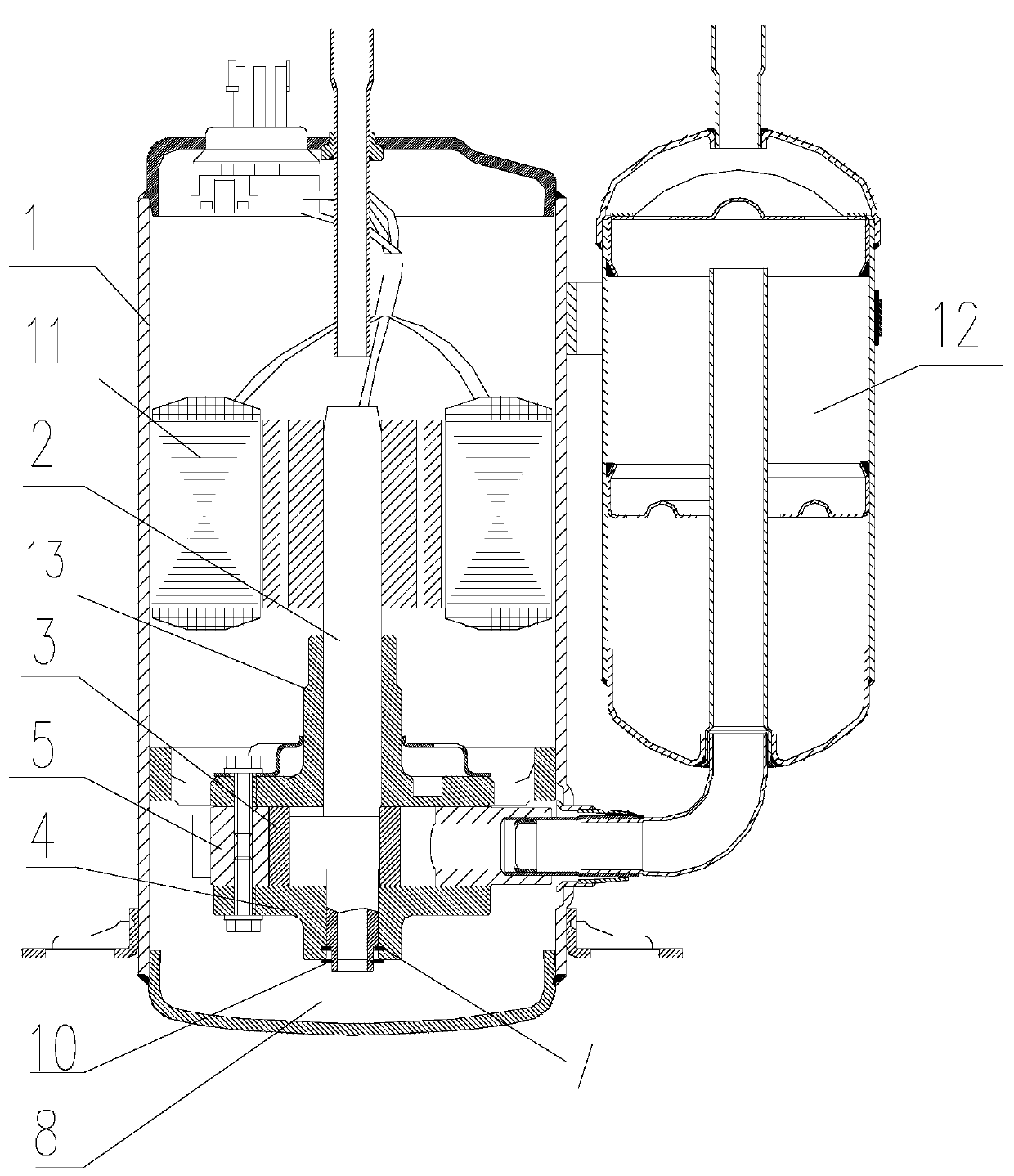

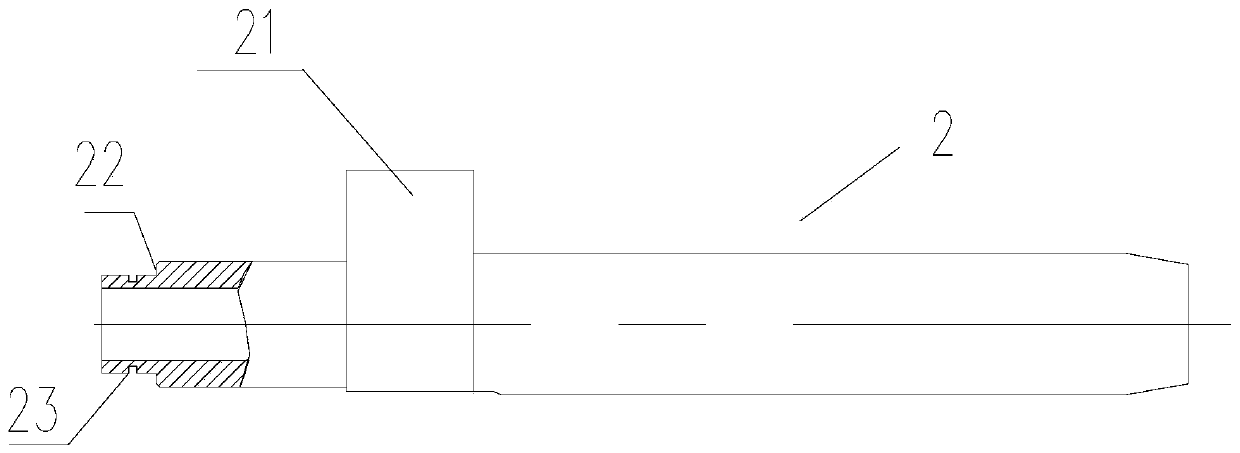

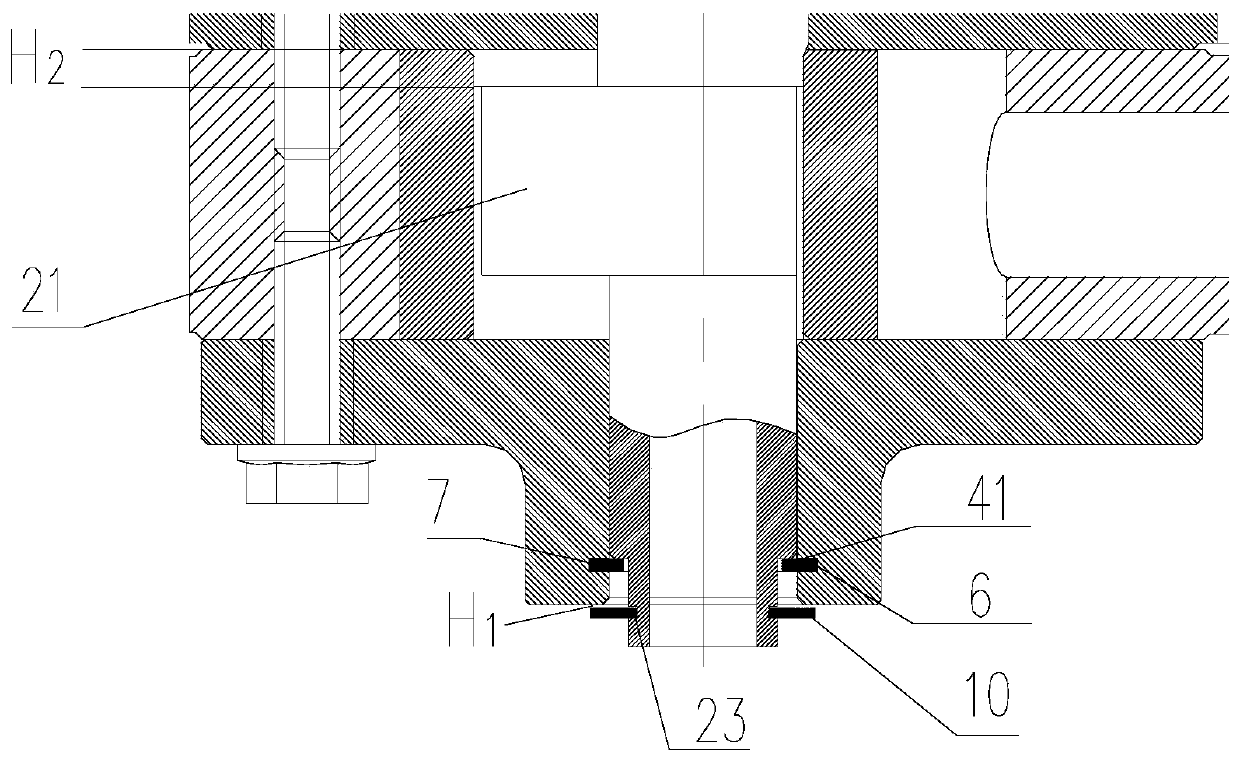

[0035] Such as figure 1 As shown, this embodiment provides a rotary compressor, including: a machine body 1; a crankshaft 2 with an eccentric portion 21, rotatably through the first bearing 3 and the second bearing 4 sleeved on both sides of the eccentric portion 21 Installed in the body 1; through the eccentric part 21, the cylinder 5 arranged in the body is driven to perform compressed gas work; between the second bearing 4 and the corresponding connection part of the crankshaft 2, an axial The limiting structure is used to maintain an axial gap between the eccentric portion 21 and the second bearing 4 .

[0036] That is, through the limiting structure, the crankshaft 2 can be lifted to a certain height, thereby preventing the contact between the eccentric portion 21 and the second bearing 4, thereby avoiding friction between the two to generate noise and cause compression Machine power consumption increases.

[0037] Such as figure 1 As shown, the rotary compressor in th...

Embodiment 2

[0052] In this embodiment, on the basis of the above-mentioned embodiment 1, the second bearing 4 is replaced by a radially narrowed part formed on the inner lower part, the transition surface of the radially reduced part is perpendicular to the rotation axis of the crankshaft 2, and the The transition surface of the radially narrowing portion forms said support surface 41 . The second bearing 4 shrinks radially inwardly to form a support surface 41, and the support surface 41 supports the bearing surface 22 of the crankshaft 2, so that the crankshaft 2 rotates vertically on the support surface 41, due to the contact between the two The area is small, so the friction generated is very small, which can effectively prevent the noise generated by friction.

[0053] As a transformable embodiment, in this embodiment, the rotary compressor described in the above-mentioned Embodiment 1 or Embodiment 2 is replaced by a horizontal position, and due to the axial limit structure, the ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com