Self-adaptive system for controlling concentration of graphene slurry

A self-adaptive system and slurry concentration technology, applied in control/adjustment system, ratio control, non-electric variable control, etc., can solve problems such as not adapting to continuous, large-scale production processes, and difficult to cope with changes in process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

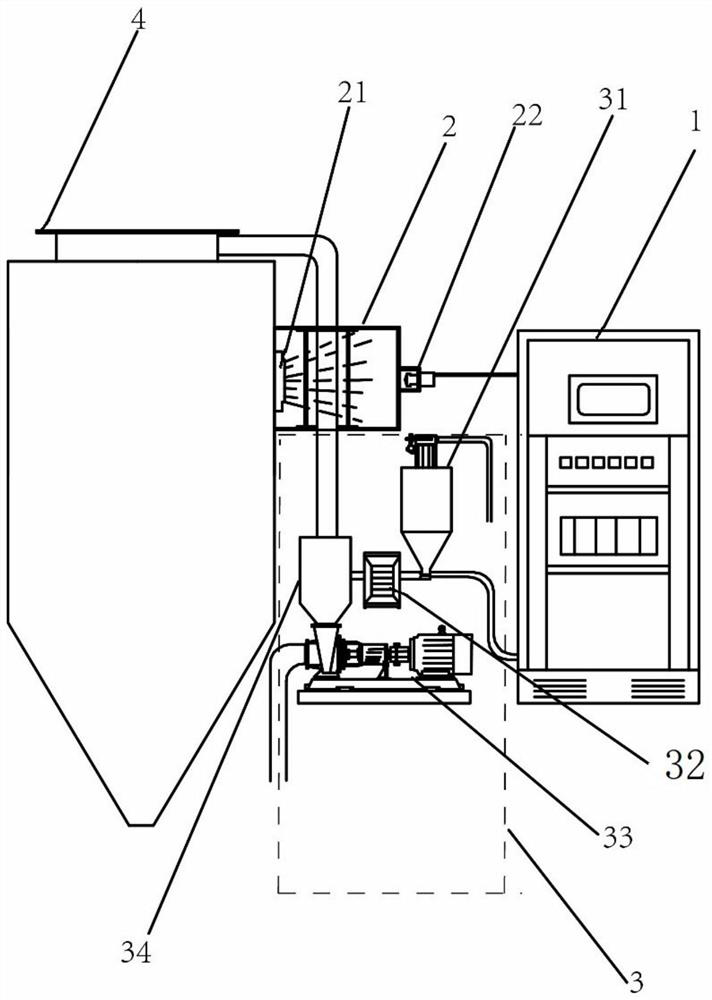

[0018] Such as figure 1 , figure 2 As shown, the self-adaptive system for graphene slurry concentration control of the present invention uses the gray value as a criterion for judging the concentration of graphene slurry, and can automatically adjust the concentration of graphene slurry products in real time.

[0019] The adaptive system for graphene slurry concentration control of the present invention comprises:

[0020] A slurry mixing unit 3 for mixing graphene powder with water to form graphene slurry;

[0021] A concentration monitoring unit 2 for detecting the concentration of the graphene slurry is connected with the slurry mixing unit 3;

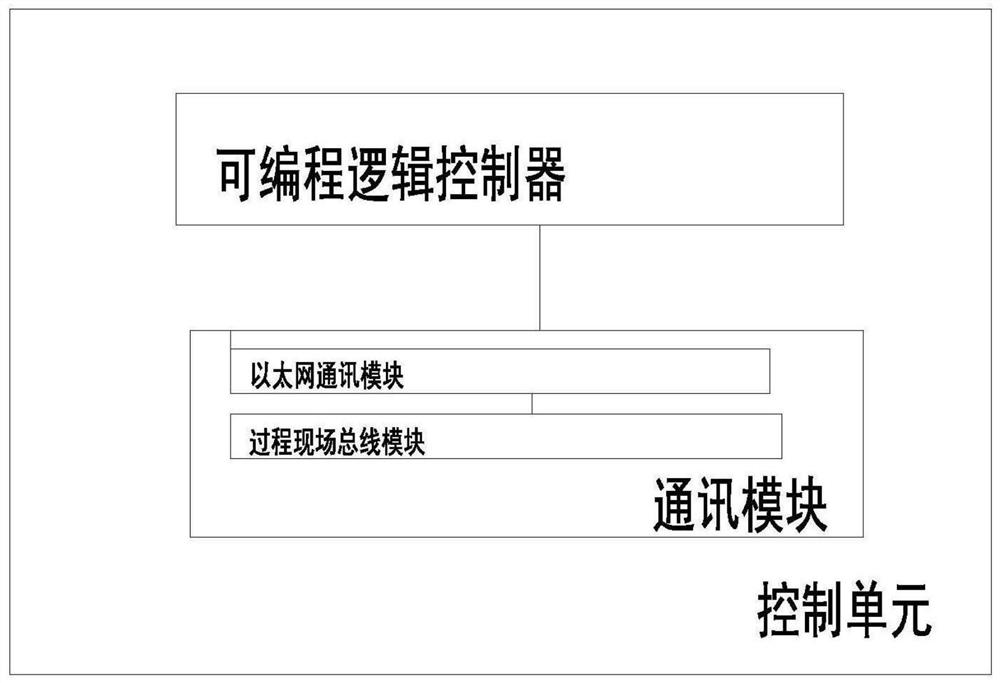

[0022] The control unit 1 is connected to the concentration monitoring unit and the slurry mixing unit respectively, and is used to operate the slurry mixing unit according to the detection result of the concentration monitoring unit, so as to control the concentration of the graphene slurry produced by the slurry mixing unit.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com