Production process management method and system

A production process and management method technology, applied in manufacturing computing systems, data processing applications, resources, etc., to solve problems such as increased inventory, large errors, and inability to supply and deliver inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

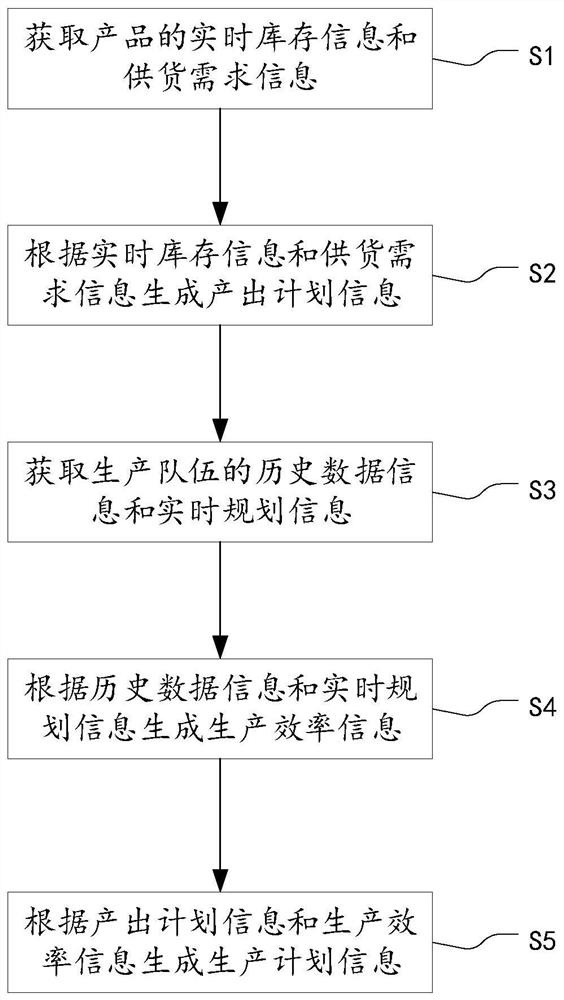

[0087] A production process management system, including a product monitoring subsystem for obtaining real-time inventory information and supply demand information of products, an output plan generation module for generating output plan information based on real-time inventory information and supply demand information, A production efficiency generating module for obtaining historical data information and real-time planning information of the production team, for generating production efficiency information based on historical data information and real-time planning information, and for generating production planning information based on output planning information and production efficiency information production plan generation module.

[0088] The various variations and specific examples of the production process management method in the foregoing embodiments are also applicable to the production process management system of this embodiment. Through the foregoing detailed des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com