Cable connector applied to rolling stock

A technology for cable joints and vehicles, applied in the direction of cable joints, etc., can solve the problem that cable joints are difficult to take into account

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

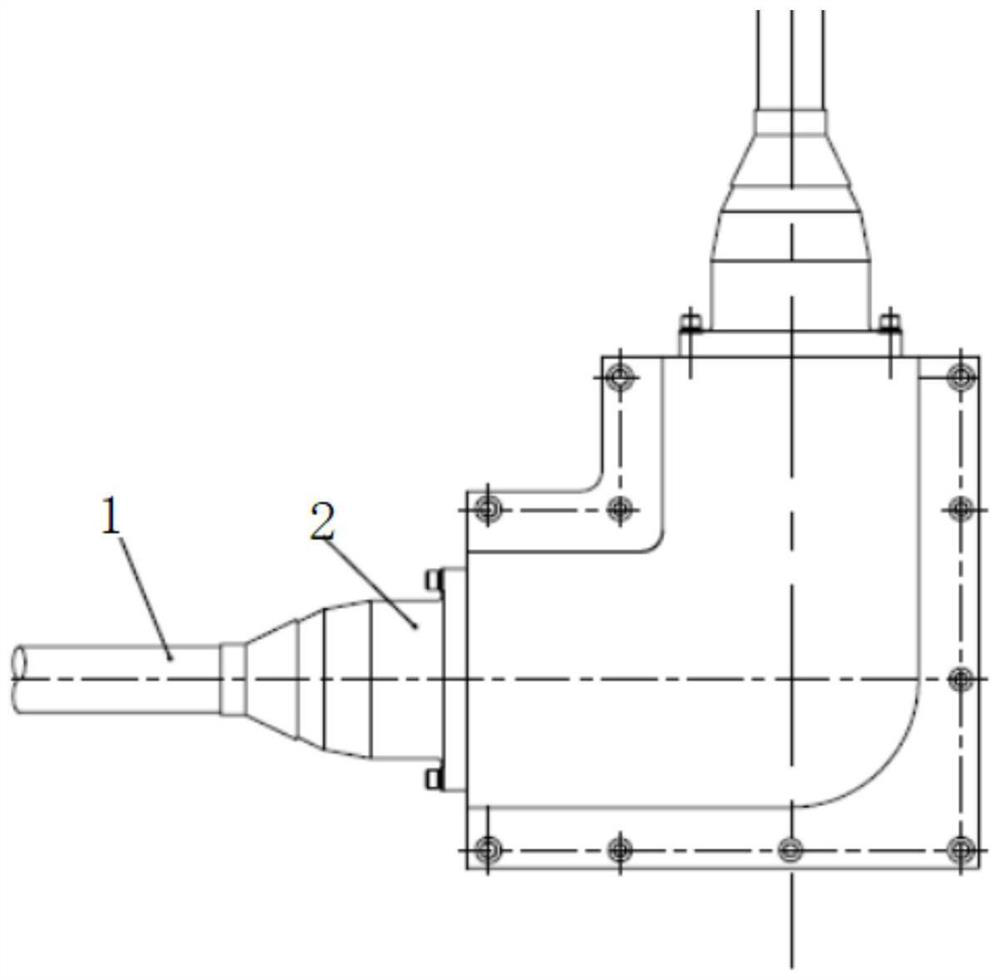

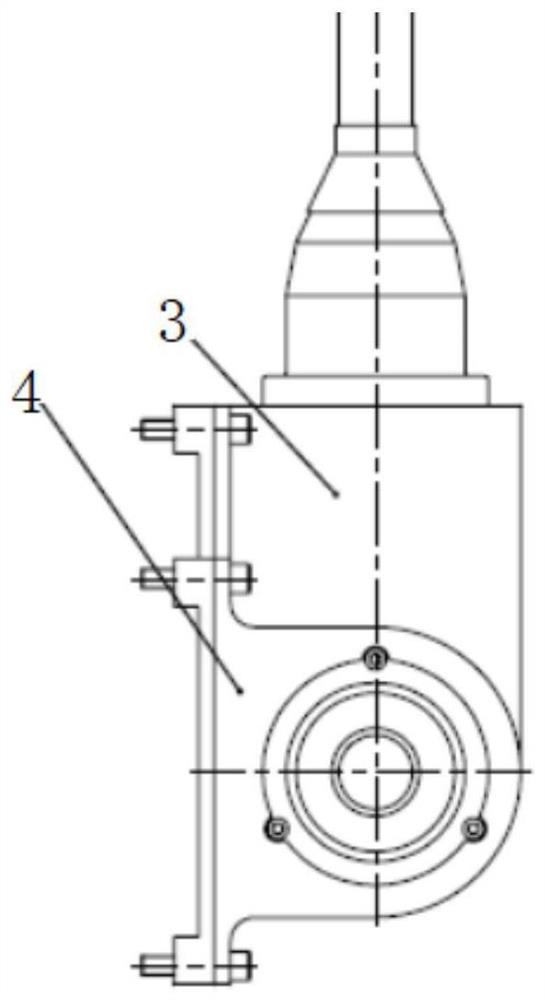

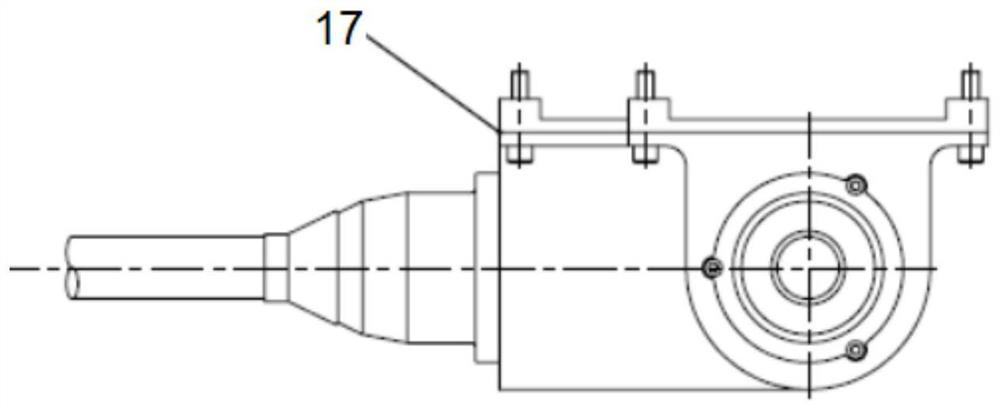

[0030] like Figure 1a , 1b , shown in 1c: the cable joint of the present invention is covered by a set of aluminum alloy casing as a whole, and is made up of tailpipe 2, casing 3 and base 4, and each other is fastened and connected by fastener 14, in order to prevent the contact surface seepage, in A sealing ring 13 is designed on the contact surface of the tail pipe 2 and the shell 3, and a sealing gasket 17 is designed on the contact surface of the shell 3 and the base 4 for protection. Ensure that the overall protection level requirements of IP66 are met.

[0031] like figure 2 As shown: the main body of the cable joint of the present invention is composed of a main insulating layer 7, a conductive rod 6, a voltage equalizing shielding layer 5 and a sprayed semi-conductive layer 15, and the shape of the main insulating layer 7 matches the shape of the shell 3 to play The role of fixing the main body of the joint is limited by the processing accuracy or manufacturing lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com