Resistance measurement device, film manufacturing device, and conductive film manufacturing method

A conductive film, resistance measurement technology, used in measurement devices, parts of electrical measurement instruments, measurement of electrical variables, etc., can solve problems such as poor surface resistance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

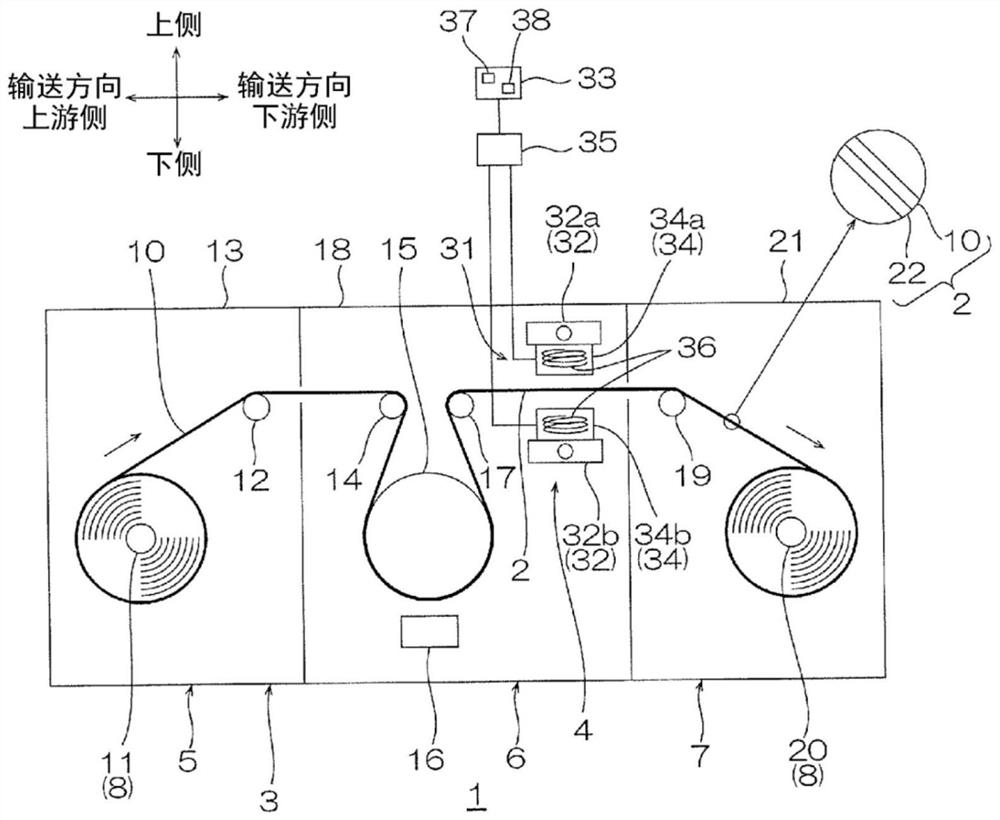

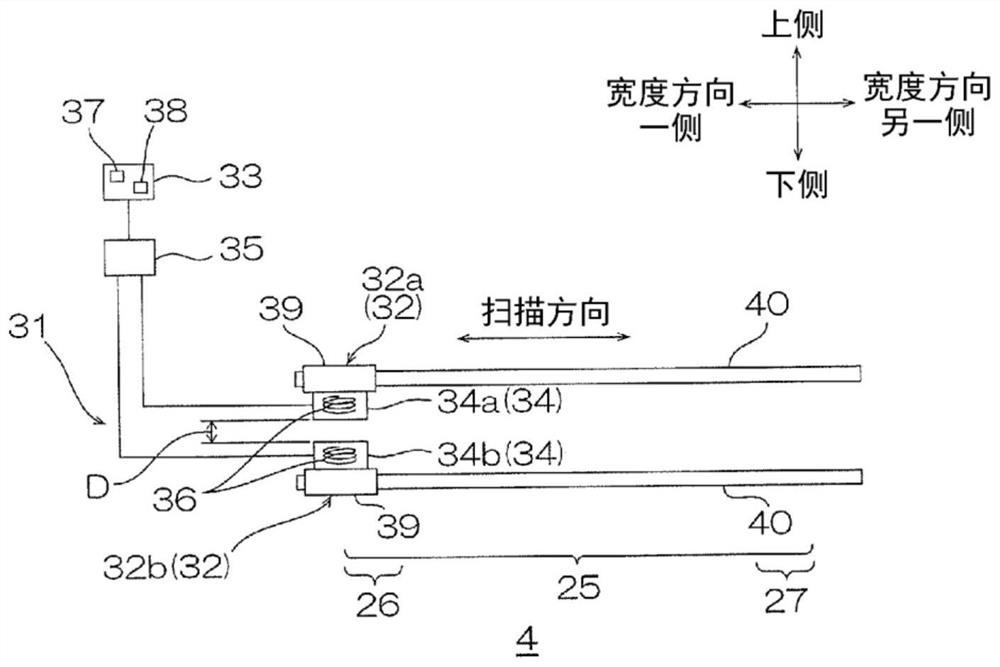

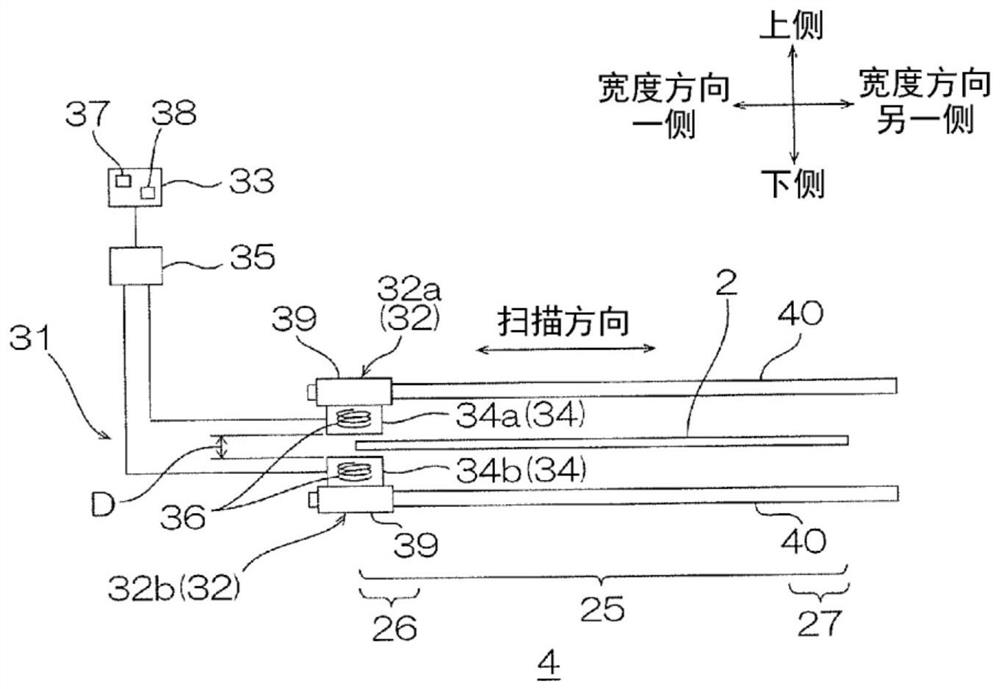

[0036] 1. Membrane manufacturing device

[0037] refer to figure 1 ˜ FIG. 3 illustrate a film manufacturing apparatus 1 according to an embodiment of the present invention. figure 1 The shown film manufacturing apparatus 1 is an apparatus for manufacturing a conductive film 2 that is long in the conveying direction (one direction), and includes a lamination conveying device 3 and a resistance measuring device 4 .

[0038] [Stacking conveying device]

[0039] Such as figure 1 As shown, the lamination conveyance apparatus 3 has the delivery unit 5, the sputtering unit 6 which is an example of a lamination unit, and the take-up unit 7.

[0040] The delivery unit 5 has a delivery roller 11 , a first guide roller 12 , and a delivery chamber 13 .

[0041] The sending-out roller 11 is a cylindrical member having a rotation shaft for sending out the base film 10 . The delivery roller 11 is disposed most upstream in the transport direction of the stack transport device 3 . A mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com