Roller coating process of an ultra-thick coating color-coated steel plate

A color-coated steel plate and coating technology, which is applied to coatings, devices for coating liquid on the surface, and surface pretreatment, etc., can solve problems such as air bubbles, streaks on the surface of the coating, and problems with coating, and achieve good results. The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

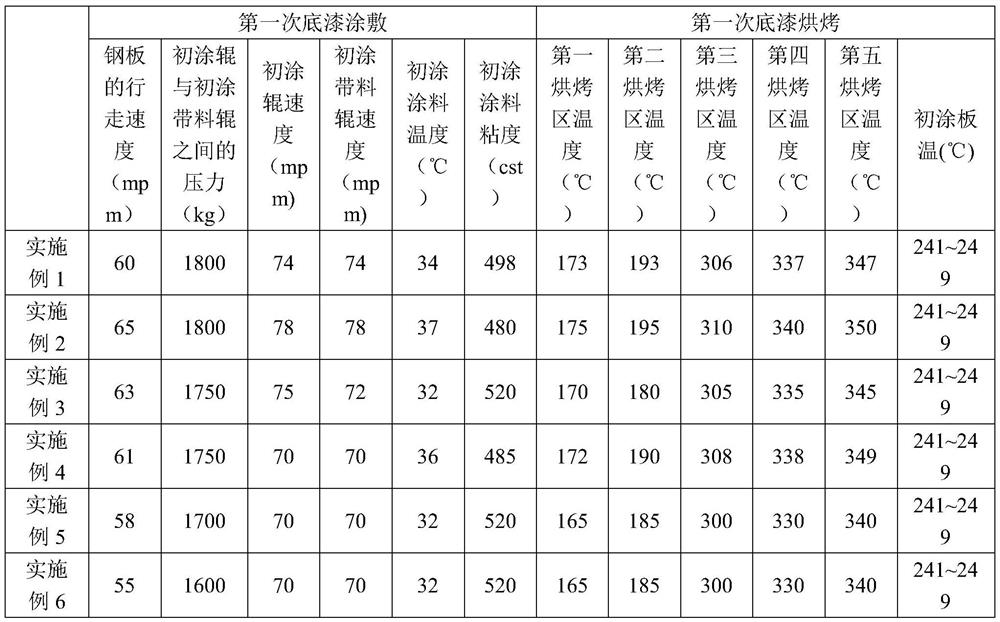

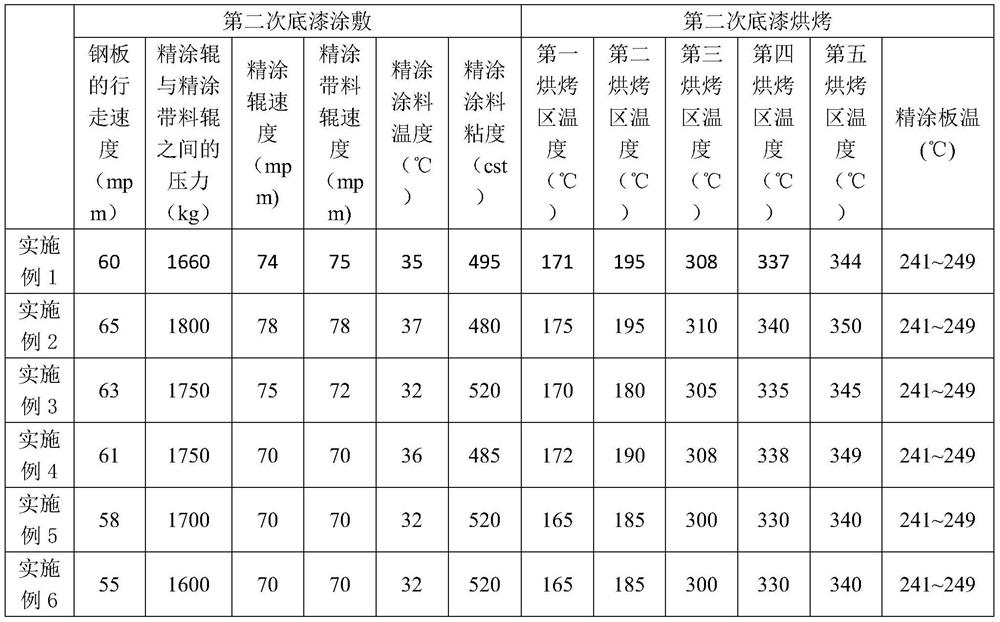

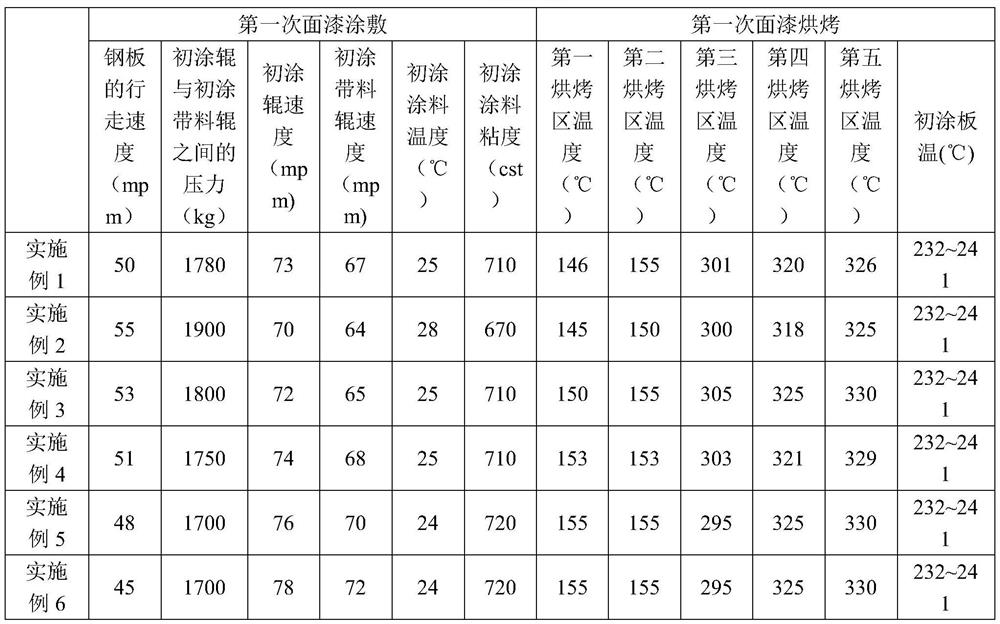

[0059] The substrate of the ultra-thick-coated color-coated steel sheet in the above-mentioned examples 1-6 is an galvanized substrate of the TDC51D+AZ grade, and the specification is 0.6*1200mm. , the roller coating process comprises at least two primer coating steps and at least two top coat coating steps, specifically as follows:

[0060] In the primer coating step for the first time, the pressure between the initial coating roller and the initial coating belt roll is controlled to be 1600-1800kg. In addition, the control coating parameters meet at least one of the following items: initial coating roller speed It is 70-78mpm; the speed of the initial coating belt roller is 70-78mpm; the temperature of the initial coating is 32-37°C; the viscosity of the initial coating is 480-520cst.

[0061] After the first primer coating step, the steel plate is baked in a baking furnace, wherein along the direction of the steel plate, the baking furnace is divided into the first baking a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com