Agricultural rapeseed screening machine

A rapeseed and screening machine technology, applied in the field of screening machines, can solve the problems of affecting screening efficiency, long time consumption of rapeseed, and insufficient screening of impurities, and achieve the effect of facilitating collection and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

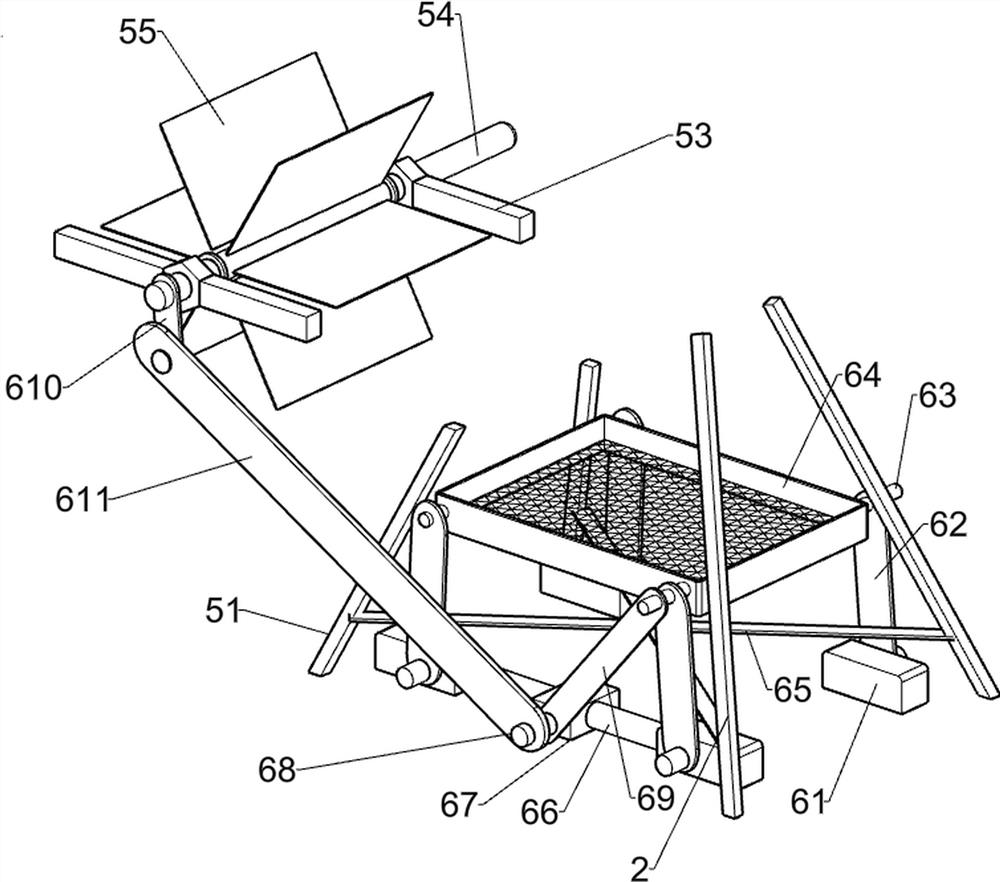

[0024] An agricultural rapeseed screening machine, such as Figure 1-3 As shown, it includes a base 1, a support column 2, a funnel 3, a baffle plate 4, a separation device 5 and a screening device 6. The right side of the top of the base 1 is symmetrically fixed with a support column 2, and a funnel 3 is arranged between the tops of the support columns 2. The lower part of the front side of the funnel 3 is connected with a baffle 4 in a sliding manner, the separation device 5 is provided on the left side of the top of the base 1 , and the screening device 6 is provided in the middle of the top of the base 1 .

[0025] When people need to use this device, first people place collection tools on the screening device 6 parts, then pour the rapeseed in the funnel 3, then start the separation device 5, then the baffle plate 4 can be pulled forward to make the separation device 5. Preliminarily separate the impurities in the rapeseed. When the rapeseed falls on the screening device ...

Embodiment 2

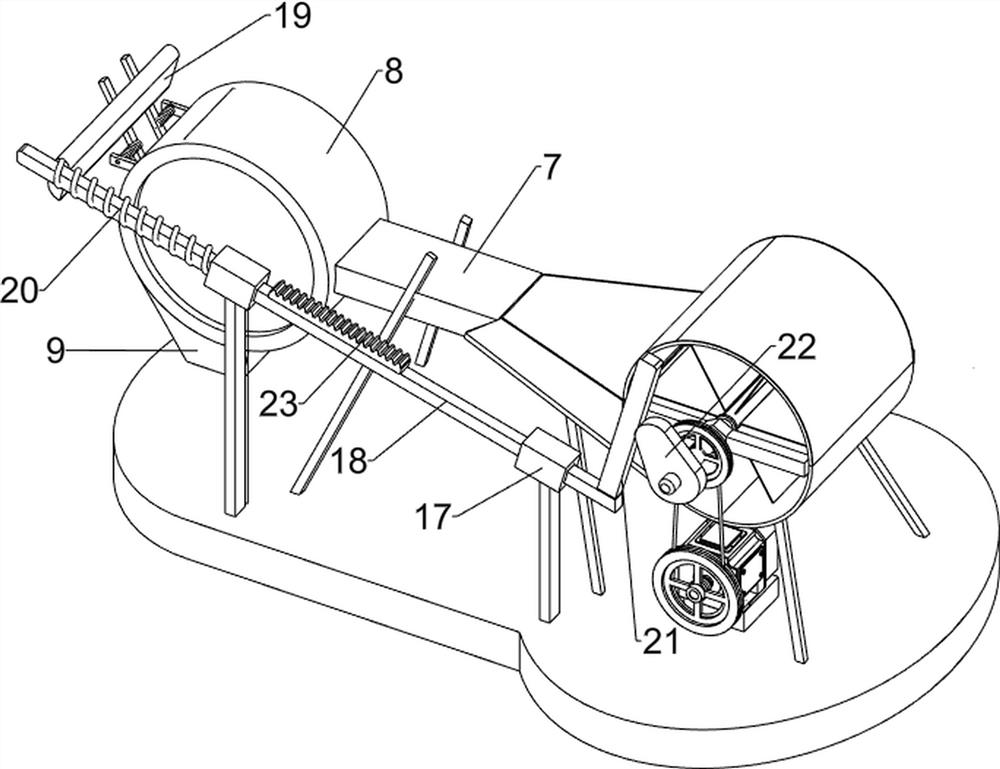

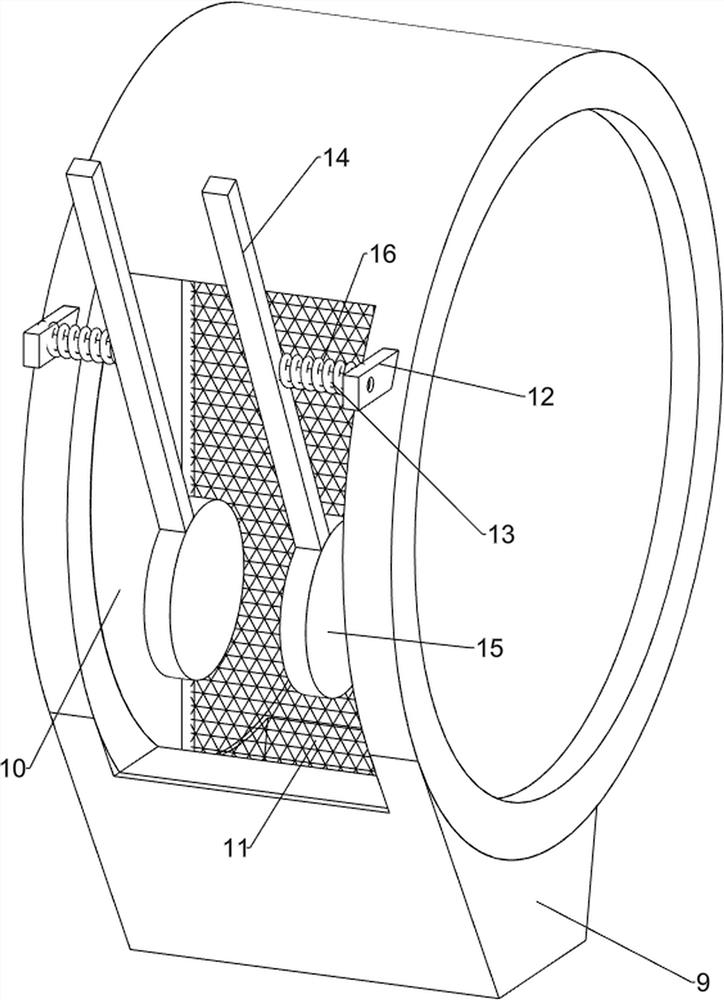

[0031] On the basis of Example 1, such as Figure 4-6 As shown, it also includes an air inlet box 7, a cylindrical barrel 8, a discharge pipe 9, a screen 11, a bearing seat 12, a first rotating rod 13, a fourth connecting rod 14, a hitting round block 15 and a first elastic member 16 , the right end of the air outlet box 58 is fixedly connected with the air inlet box 7, the bottom of the funnel 3 is connected with the air outlet box 58 and the air inlet box 7, the right end of the air inlet box 7 is connected with a cylindrical barrel 8, and the bottom of the cylindrical barrel 8 is provided with a discharge pipe 9, and the cylindrical barrel 8 is connected with the air inlet box 7. There are arc-shaped grooves 10 between the discharge pipes 9, a screen 11 is provided in the cylindrical barrel 8, and a bearing seat 12 is arranged symmetrically on the upper part of the right side of the cylindrical barrel 8. Rotating rod 13, the end of the first rotating rod 13 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com