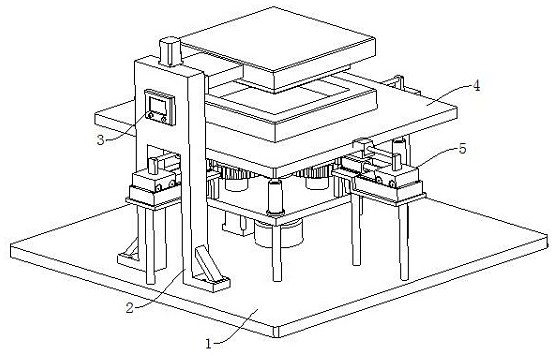

A split-flow die for aluminum alloy extrusion molding and its working method

An extrusion molding and flow splitting technology, which is applied to metal extrusion dies and other directions, can solve the problems that the flow splitting effect needs to be improved, the internal structure is not designed, and the pressure of the aluminum alloy material cannot be guaranteed, so as to improve the flow splitting effect and forming efficiency. Ease of care and maintenance, the effect of reducing frictional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

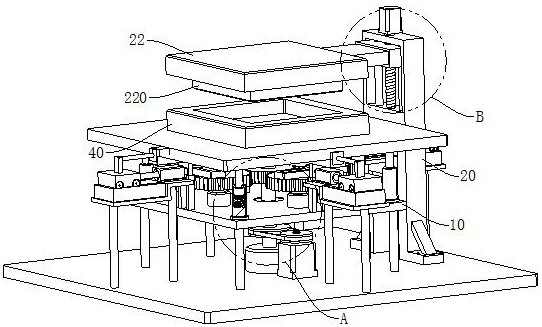

[0042] The technical scheme of the present invention is further described below in conjunction with the accompanying drawings and through specific embodiments.

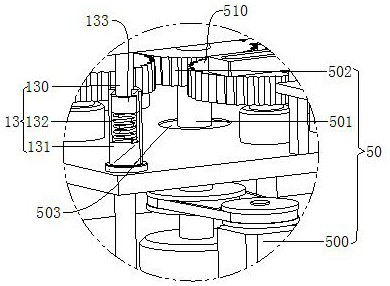

[0045] The drive assembly 50 includes a servo motor 500, a rotating shaft 501 and a driving gear 502. The servo motor 500

[0046] The rotating assembly 51 includes four driven gears 510, and the top of the support plate 10 is symmetrically provided with four

[0049] The lifting assembly 21 includes a slider 210, a micro-motor 211 and a lead screw 212, and the top of the vertical plate 20 is integrally formed

[0052] The center of the support plate 10 is provided with a receiving groove for the bearing 503 to be installed, and the inner ring of the bearing 503 is connected to the rotating

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com