Improved expansion pressing system and method therefor

An improved and expanded technology, applied in the directions of transportation and packaging, metal processing, metal processing equipment, etc., can solve the problems of increased labor intensity, low processing efficiency, and difficulty in meeting the concentricity of the flip shaft assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

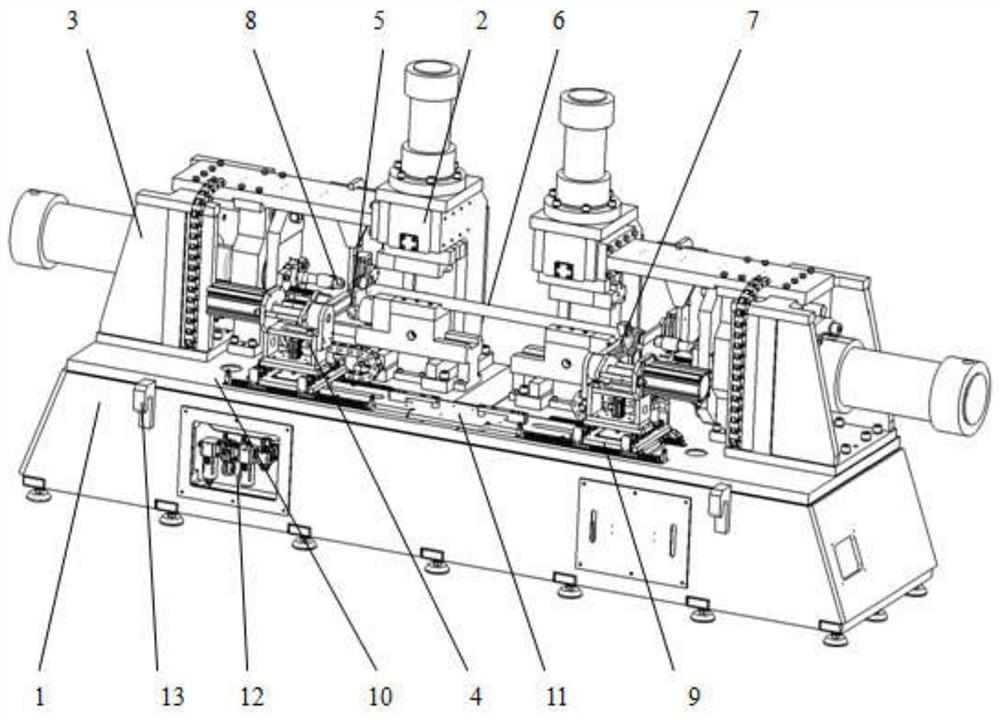

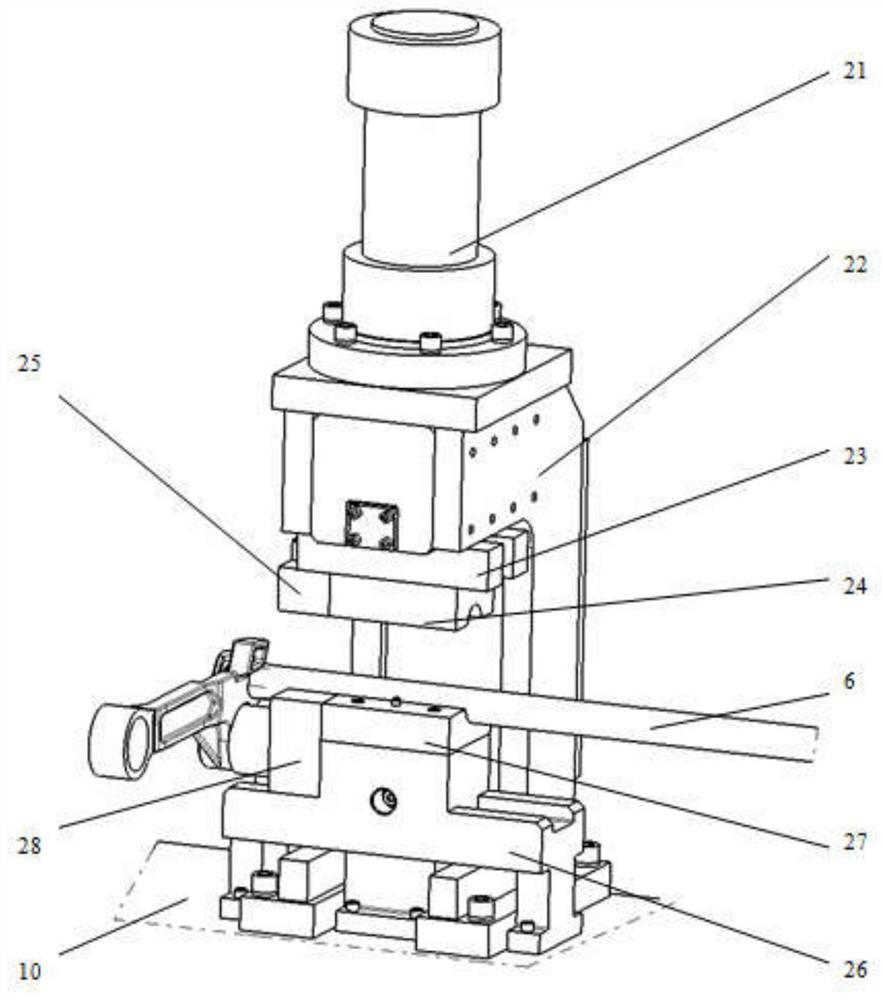

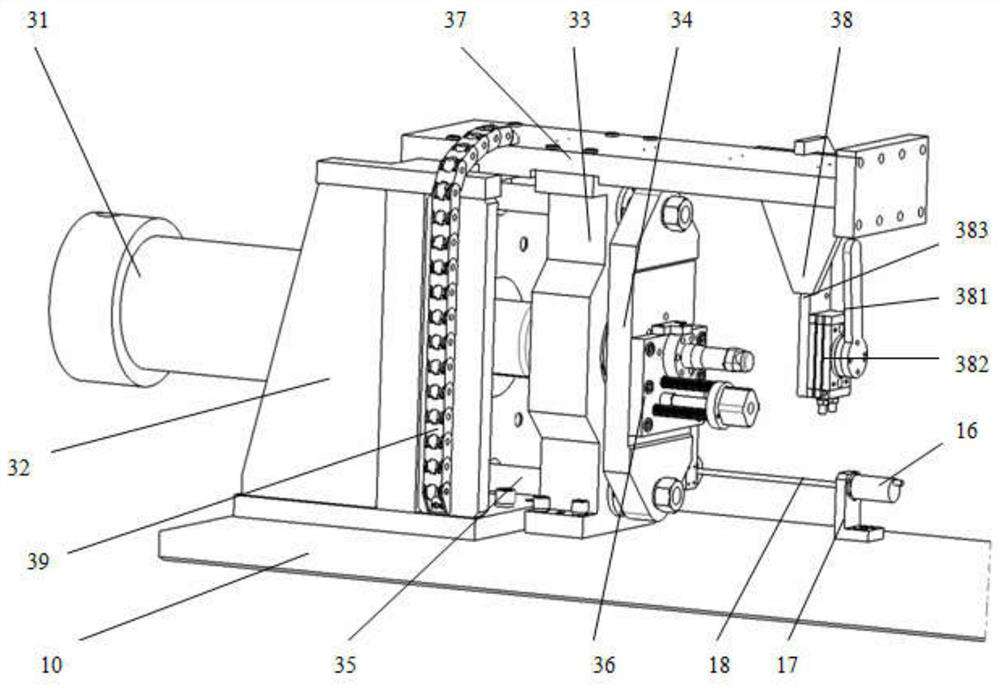

[0051] Such as Figure 1-Figure 7As shown, the improved expansion type press-fit system includes a press-fit mechanism 2 and a press-fit mechanism 3; the press-fit mechanism 2 is used to press the balance bar 6; Press-fit into the balance bar 6 in the same way. The pressing mechanism 2 and the pressing mechanism 3 are all arranged on the frame 1, and the frame 1 is also provided with a slide table transmission mechanism 9, and the slide table transmission mechanism 9 is provided with a mounting bracket for fixing the left rocker arm 5 and the right rocker arm 7 respectively. Two positioning jigs 4. The improved expansion type press-fitting system 100 also includes: a console and an alarm system for allowing the staff to operate; the console and the alarm system for allowing the staff to operate are all electrically connected with the electric control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com