Robot telescopic arm

A telescopic arm and robot technology, applied in the field of robotics, can solve problems such as difficult to control the telescopic length, and achieve the effect of precise telescopic control, reduced volume, and easy telescopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

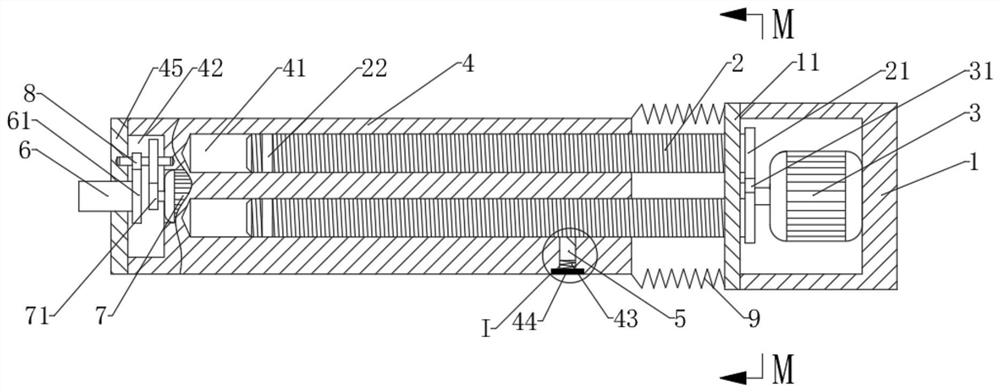

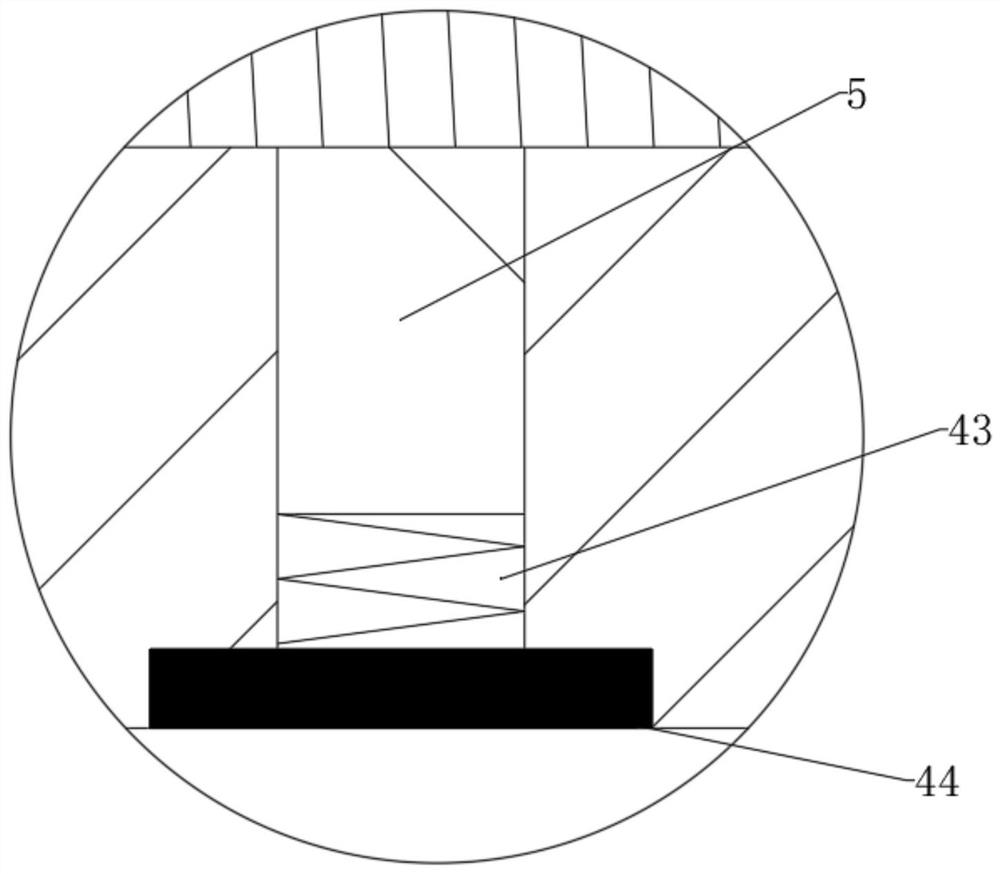

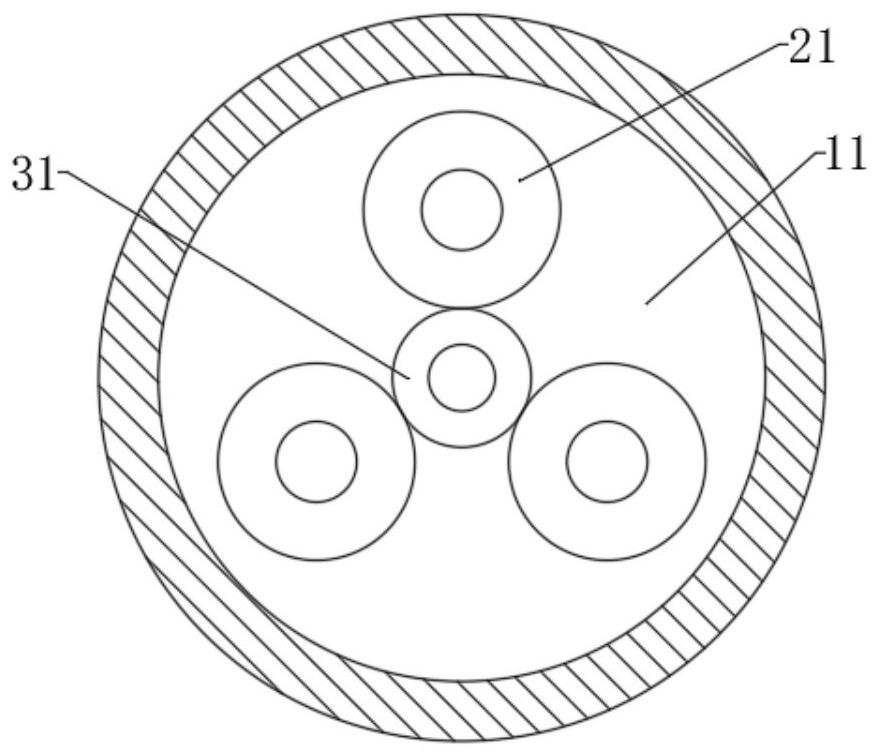

[0024] Depend on Figure 1 ~ Figure 3 As shown, a telescopic arm of a robot comprises a fixed arm 1, a first motor 3 is arranged in the fixed arm 1, and at least three sets of lead screws 2 uniformly distributed around the axis of the fixed arm 1 are also provided on the fixed arm 1, and the lead screw 2 is connected with the first motor 3, and the first motor 3 drives the lead screw 2 to rotate at the same time, the lead screw 2 is covered with a telescopic arm 4, and the telescopic arm 4 is provided with at least three groups of wires evenly distributed around the axis of the telescopic arm 4 The screw hole 41, the leading screw 2 is connected with the leading screw hole 41, and the end of the telescopic arm 4 near the fixed arm 1 is provided with a limiting unit that prevents the leading screw 2 from breaking away from the leading screw hole 41;

[0025] The fixed arm 1 is cylindrical with an opening at one end, the mouth of the fixed arm 1 is fixedly connected with a first...

Embodiment 2

[0031] Depend on Figure 1 ~ Figure 3 As shown, a telescopic arm of a robot comprises a fixed arm 1, a first motor 3 is arranged in the fixed arm 1, and at least three groups of lead screws 2 uniformly distributed around the axis of the fixed arm 1 are also provided on the fixed arm 1, and the lead screw 2 is connected with the first motor 3, and the first motor 3 drives the lead screw 2 to rotate at the same time, the lead screw 2 is covered with a telescopic arm 4, and the telescopic arm 4 is provided with at least three sets of wires evenly distributed around the axis of the telescopic arm 4 The screw hole 41, the leading screw 2 is connected with the leading screw hole 41, and the end of the telescopic arm 4 near the fixed arm 1 is provided with a limiting unit that prevents the leading screw 2 from breaking away from the leading screw hole 41;

[0032] Preferably, in this embodiment, the telescopic arm 4 is further provided with a rotating motor chamber 42 at the end away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com