Winding device

A winding device and winding frame technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material processing, etc., which can solve the problems of not easy to wind neatly, heavy grounding wires, and great effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

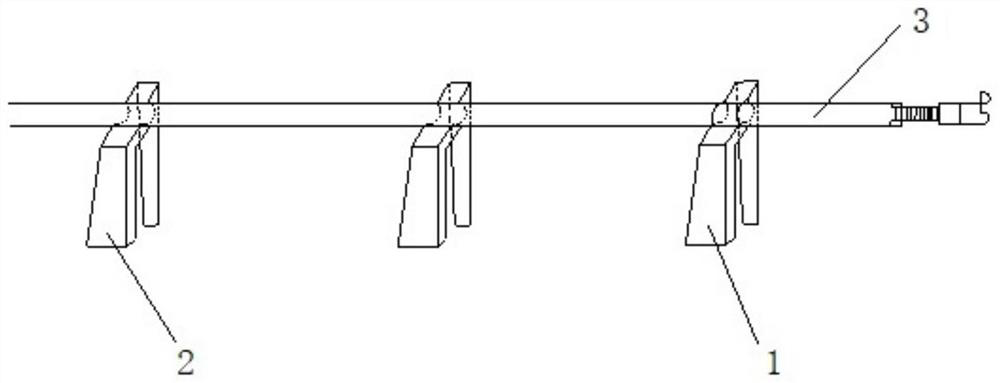

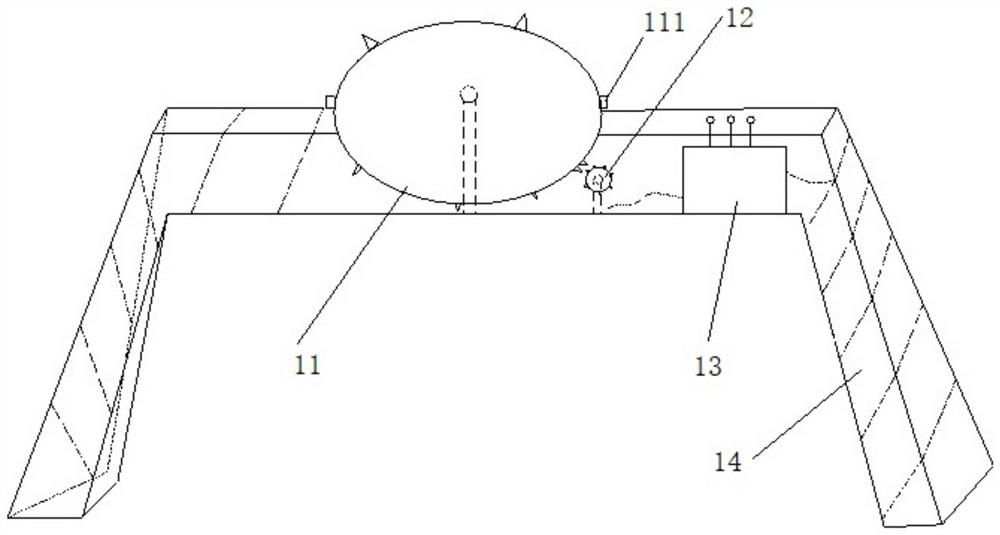

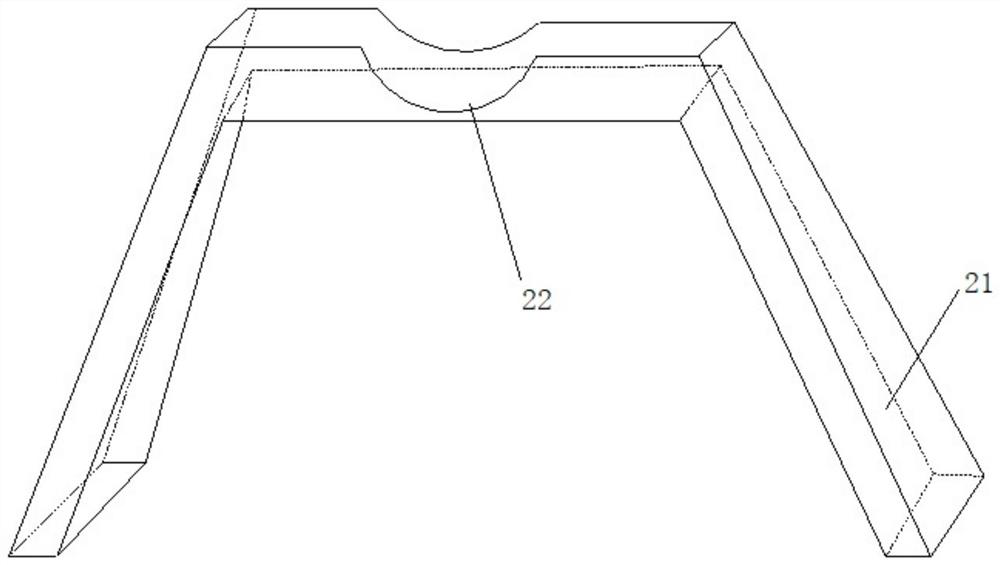

[0031] Such as Figure 1-Figure 3 As shown, the present invention provides a winding device, including a winding frame 1 , a support frame 2 and a grounding rod 3 . The winding frame 1 is provided with a turntable 11, a motor 12 and a battery 13. The turntable 11 is vertically arranged and can be connected to the top of the winding frame 1 by rotating around a horizontal axis. The axis of the turntable 11 is provided with an engaging hole, and the battery 13 is connected to the motor. 12 is electrically connected, and the motor 12 can drive the turntable 11 to rotate. The support frame 2 is provided with a plurality, the support frame 2 is provided with a plurality, the support frame 2 top surface is provided with a support groove 22, the support groove 22 is connected to the front and rear side walls of the support frame 2, and the left and right sides of the support frame 2 are provided with installation grooves 21 , the winding frame 1 and multiple support frames 2 can be ...

Embodiment 2

[0043] This embodiment provides a winding device, which is further improved on the basis of the first embodiment, so that the height of the winding frame 1 and the support frame 2 can be adjusted, so that the wires installed on the winding frame 1 and the support frame 2 The grounding rod 3 is always kept horizontal along the axial direction to ensure the stable rotation of the grounding rod 3 .

[0044] Optionally, the bobbin frame 1 and the support frame 2 are provided with telescopic parts, and the telescopic parts can be telescopically adjusted so that the bobbin frame 1 and the support frame 2 are at the same level. In this embodiment, the telescopic part is arranged on the support legs on the left and right sides of the winding frame 1 and the support frame 2, and the support legs on the left and right sides of the winding frame 1 and the support frame 2 can be adjusted by telescopic adjustment, so that the winding frame 1 can It is adjusted to the same level as the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com