Novel railway road shoulder structure and construction method

A technology of road shoulder and railway, applied in the field of new type railway shoulder structure and construction, can solve the problem of no prefabricated shoulder protection structure, etc., and achieve the effect of improving the aesthetic effect, smooth drainage, convenient and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

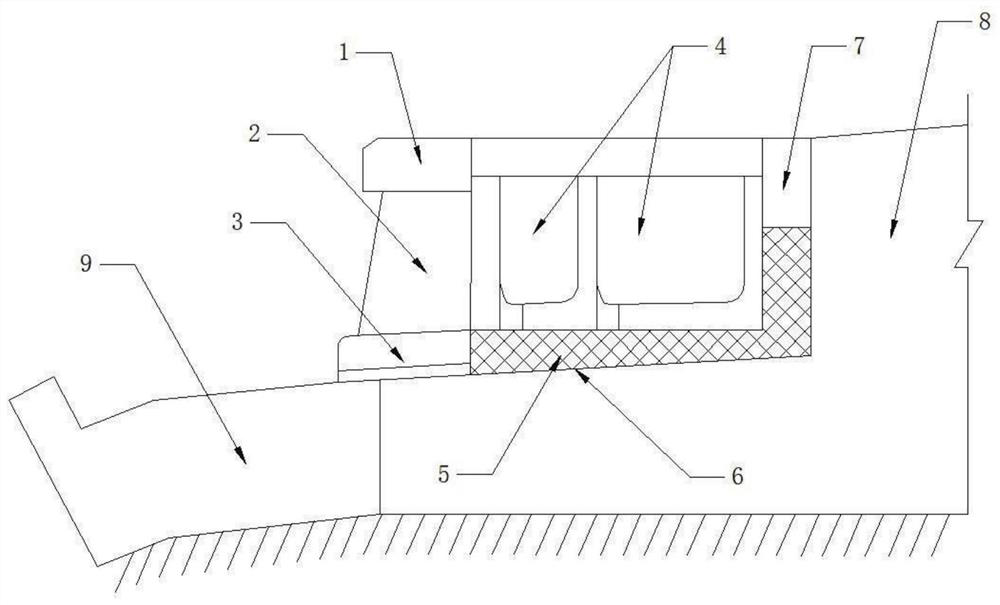

[0035] In the embankment section, the first 100mm of the third road shoulder block 3 is placed on the embankment trim 9 , and the rear 200mm is placed on the bed filler 8 . The accumulated water in the cable trough 4 flows to the permeable gravel layer 5 through the drain hole at the bottom, and is discharged through the drain hole of the third road shoulder block 3, and flows into the slope drainage system.

Embodiment 2

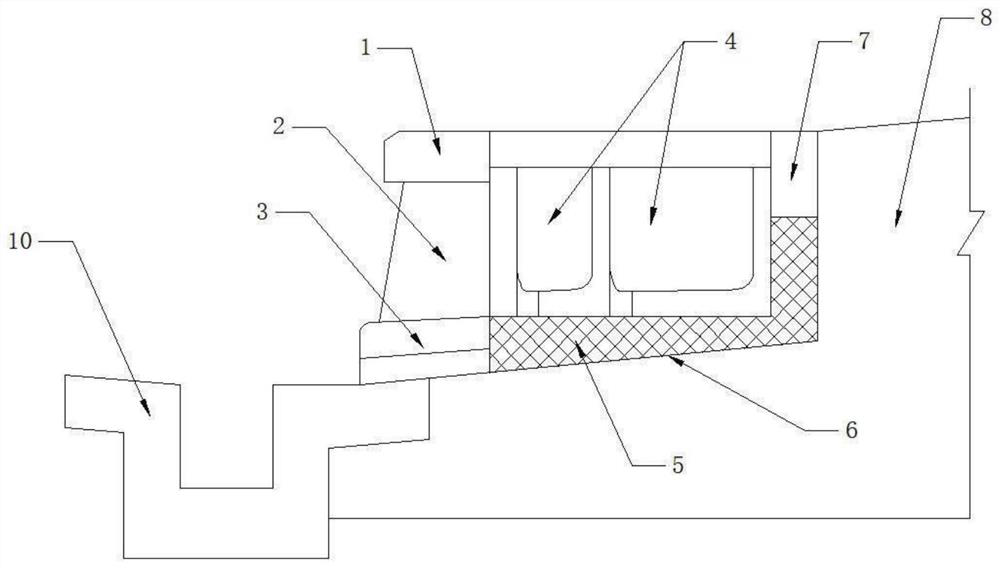

[0037] In the cutting section, the first 100 mm of the third road shoulder stopper 3 is located above the cutting side ditch 10 , and the rear 200 mm is placed above the bed filler 8 . The accumulated water in the cable trough 4 flows to the permeable gravel layer 5 through the drain hole at the bottom, and is discharged through the drain hole of the third road shoulder block 3, and flows into the cutting side ditch 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com