Strength and reliability test device and method for longitudinal roller guide rail mechanism

A technology of roller guide rail and test device, which is applied in the direction of strength characteristics, measuring devices, and the use of stable tension/pressure test material strength, etc., which can solve the problems of bearing pressure, and may also bear tension, proximity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

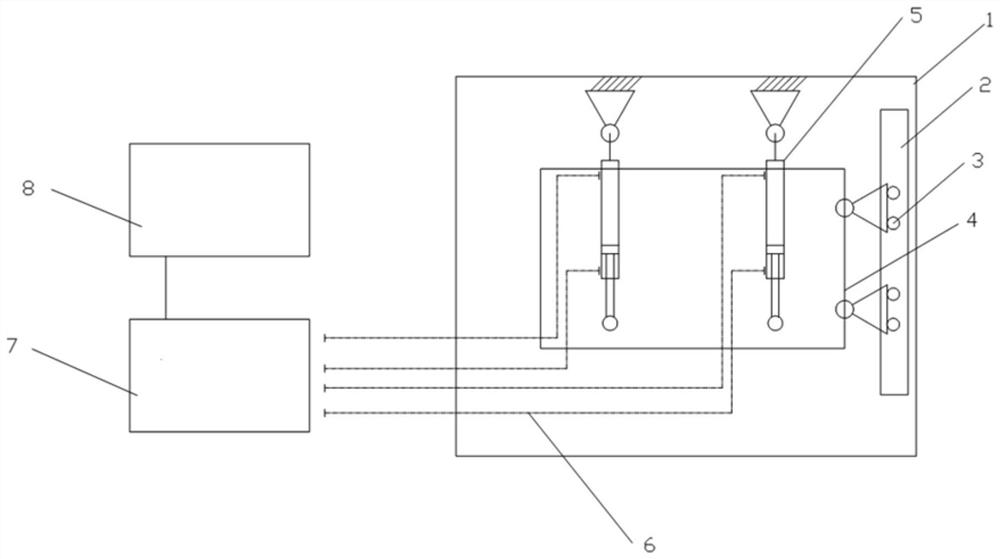

[0029] In a typical embodiment of the present invention, such as figure 1 As shown, this embodiment discloses a strength and reliability test device for a longitudinal roller guide rail mechanism, including a frame 1 fixed on a plane or a workbench and a simulation platform 4 placed inside the frame 1, and the longitudinal guide rail is fixed on the frame 1 , the roller mechanism is fixed on the simulation platform 4, and the roller mechanism and the longitudinal guide rail are slidingly connected to form a roller guide mechanism, so that the simulation platform 4 can move in the vertical direction through the roller guide mechanism.

[0030] More specifically, in this embodiment, the frame 1 is a rectangular parallelepiped frame 1, and the simulation platform 4 moves in the frame 1, so the shape of the simulation platform 4 is limited by the frame 1, and the projection on the plane is also rectangular.

[0031] In this embodiment, what is to be measured is the roller guide ra...

Embodiment 2

[0049] A strength and reliability test method for a longitudinal roller guide mechanism, using the strength and reliability test device for a longitudinal roller guide mechanism as described in the first aspect, through controlling the expansion and contraction of the hydraulic cylinder 5 multiple times, driving the simulation platform 4 relative to The frame 1 reciprocates to simulate the actual use of the roller guide rail mechanism. The distance sensor used measures the movement height of the simulated platform 4, and the tension and pressure force between the roller and the simulated platform 4 is measured by the pressure sensor.

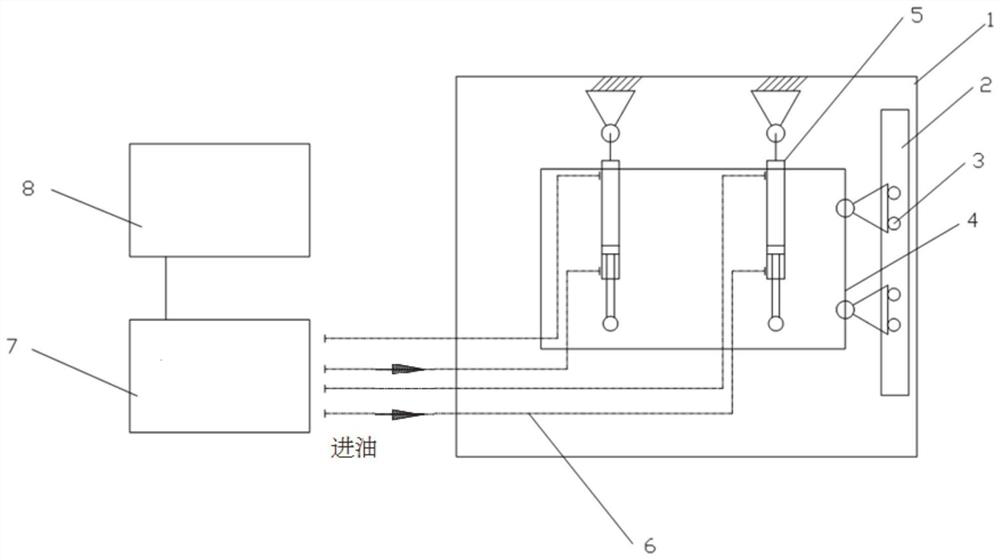

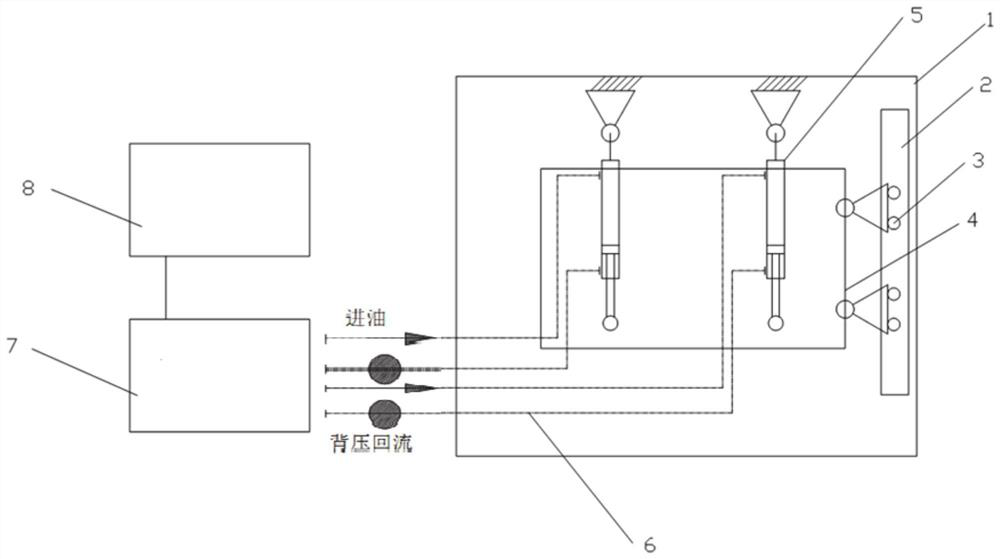

[0050] Wherein, the concrete operating process of hydraulic cylinder 5 is as follows:

[0051] Free Ascent: If figure 2 As shown, the bottom of the two hydraulic cylinders 5 feeds oil, and the top oil returns to open. Under the action of the bottom oil pressure, the simulation platform 4 rises, the head space of the hydraulic cylinders 5 decrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com