Rotary stepping type cable buffer layer ablation fault simulation device and method

A fault simulation device and buffer layer technology, applied in the direction of measurement device, measurement of electricity, measurement of electrical variables, etc., can solve the problem that the aluminum bellows-water blocking buffer layer structure cannot be simulated in the laboratory, and the buffer layer ablation cannot be reproduced. , the inability to prepare a large number of buffer layer ablation samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

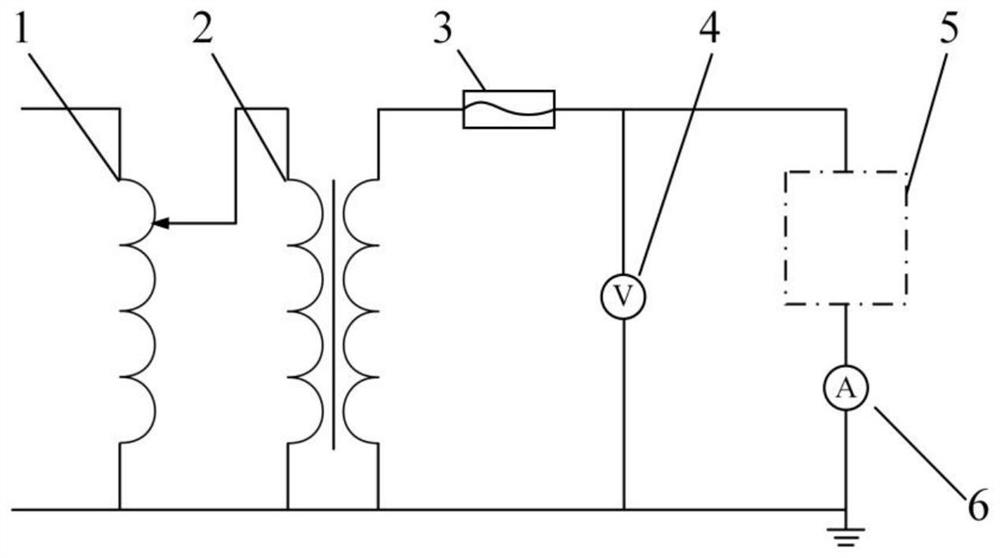

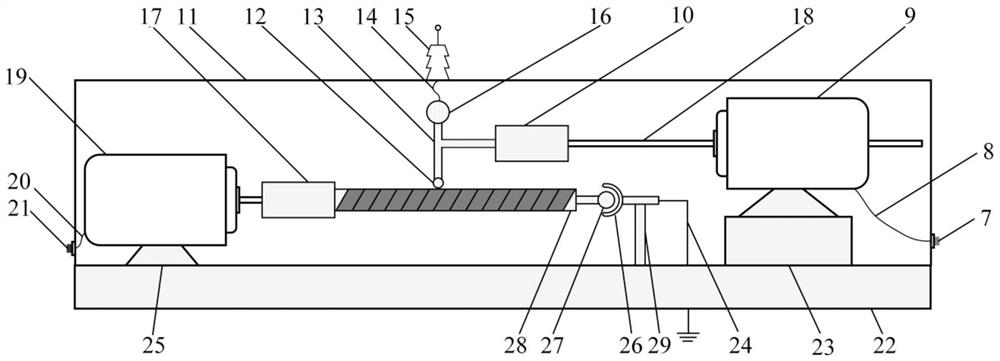

[0036] This embodiment provides a rotating step-by-step cable buffer layer ablation fault simulation device such as figure 1 As shown, it includes a power frequency voltage loop unit for providing a voltage applied to the buffer layer and a buffer layer experiment unit 5 connected to the power frequency voltage loop unit for simulating the ablation failure of the buffer layer.

[0037] Such as figure 1 As shown, the power frequency voltage loop unit includes a voltage regulator 1 , a power frequency test transformer 2 , a fuse 3 , a voltmeter 4 and an ammeter 6 . The input end and output end of the voltage regulator 1 are respectively connected with the 220V mains and the input end of the power frequency test transformer 2 . The output end of the power frequency test transformer 2 is connected to the buffer layer test unit 5 through the fuse 3 . The voltmeter 4 is connected in parallel to both ends of the buffer layer experiment chamber 5 . The ammeter 6 is connected in ser...

Embodiment 2

[0045] In this example, take the actual 110kV high-voltage cable water-blocking buffer layer, cut it into a strip structure with a width of 50mm and a length of 1000mm, and then place it in an environment of 120°C and 0.008Mpa to dry for 24 hours, as this example Medium cable water-blocking buffer layer sample.

[0046] This embodiment provides a method for simulating the ablation fault of the rotary stepping cable buffer layer. Using the rotary stepping cable buffer layer ablation fault simulation device in Example 1, the high voltage cable is simulated under the set voltage amplitude. Buffer layer ablation simulation experiment, the specific steps are as follows:

[0047] (1) Drying of the buffer layer experimental unit 5: remove the shell 11 of the buffer layer experimental chamber, wipe it carefully with a non-woven cloth, and then vacuum-dry the components of the buffer layer experimental unit 5 at a drying temperature of 80°C. The drying vacuum degree is 0.008Mpa, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com