power feed system

A technology of power feeding and power, which is applied in the field of power feeding systems, and can solve problems such as increased loss and increased loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

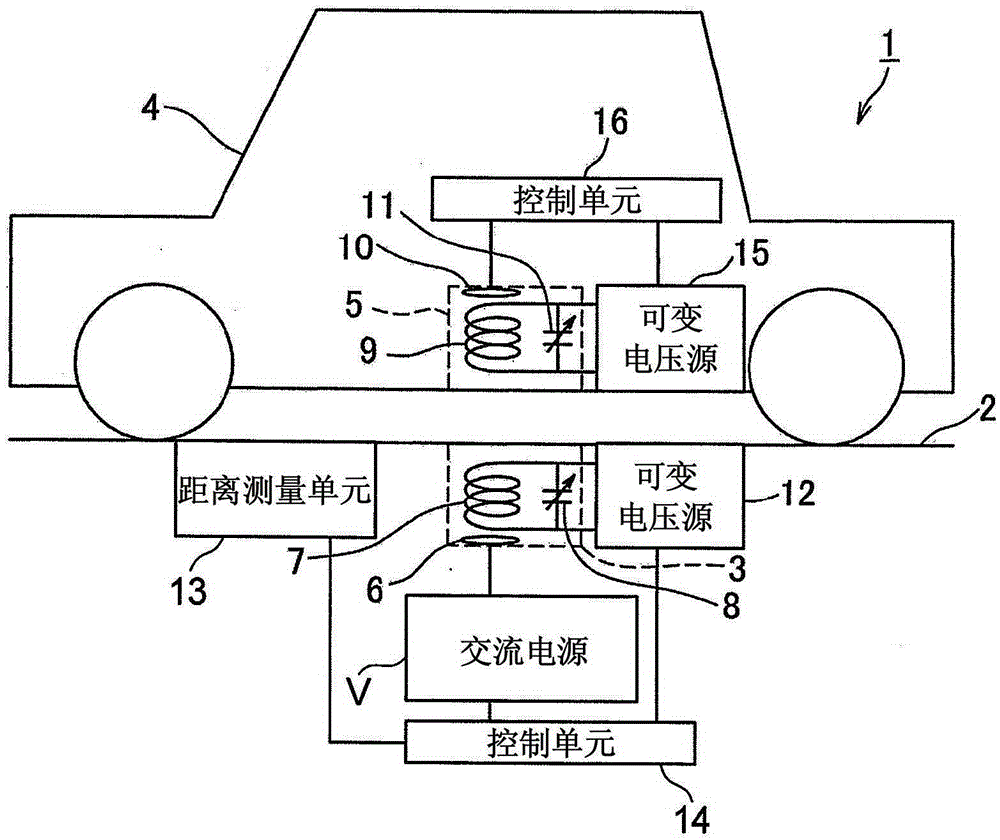

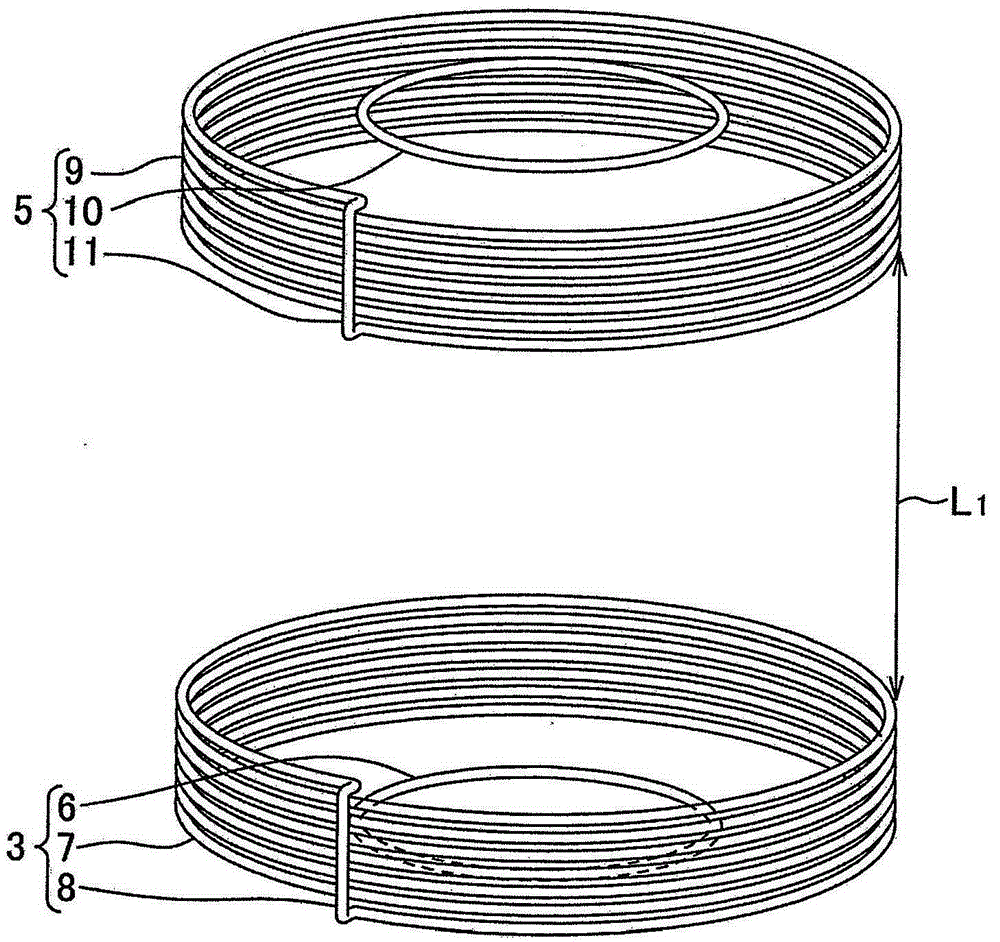

[0091] Hereinafter, the power feeding system of the present invention is described with reference to the drawings. figure 1 The power feeding system of the present invention is shown in the first embodiment. figure 2 to show figure 1 Perspective view of the construction of the power feed system shown. Such as figure 2 As shown, the power feeding system 1 has: a power feeding unit 3 provided on a road 2 as a feeding member; and a power receiving unit 5 installed in the body of an automobile 4 .

[0092] Such as figure 1 and figure 2 As shown, the above-mentioned power feeding unit 3 has: a power feeding side loop antenna 6 to be supplied with power; a power feeding side helical coil 7, as a power feeding side coil, electromagnetically coupled with the power feeding side loop coil 6; A diode 8, as a capacitor, is connected in parallel with the power feeding side helical coil 7. This power feeding side loop antenna 6 has a circular shape whose axis is arranged in the ...

no. 2 example

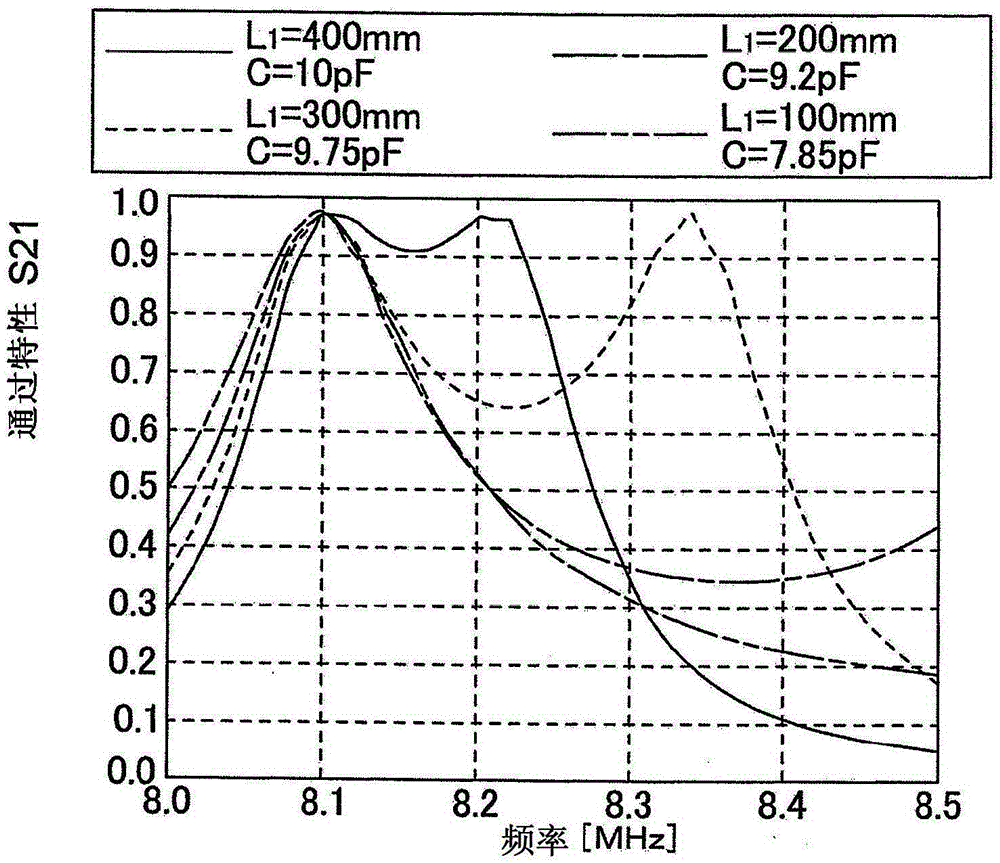

[0121] Next, a second embodiment will be described. Although in the first embodiment described above, based on the inter-coil distance L measured by the distance measuring unit 13 1 , to adjust the capacitance C of the varactor diodes 8, 11 on the power feeding side and the power receiving side, but in the second embodiment, on the other hand, as Figure 7 As shown, it is conceivable that instead of the distance measuring unit 11, a reflection measuring unit 18 is provided in the automobile 4 for measuring the reflection amount of the power receiving side helical coil 9, the power feeding side varactor 8 is removed, and the power receiving side is separately provided The varactor 11, and the capacitance C of the power receiving side varactor 11 is adjusted by the control unit 16, so that the reflection characteristic S21 is improved. It should be noted that the above-mentioned reflection measurement unit 18 is a unit that measures the power fed to the power receiving side hel...

no. 3 example

[0130] Next, a power feeding system of the present invention in a third embodiment will be described with reference to the drawings. Figure 10 The power feeding system of the present invention in the third embodiment is shown. Figure 11A and Figure 11B respectively show the depiction Figure 10 Schematic perspective and side views of the structure of the power feed system shown. In these figures, for figure 1 Corresponding parts of the power feeding system shown in the first embodiment described above are affixed with the same reference symbols, and a detailed description thereof is omitted. As shown in these figures, the third embodiment differs from the first embodiment in the absence of variable capacitors 8, 11, variable voltage sources 12, 15, distance measuring unit 13 and control units 14, 16 and power receiving The structure of the side loop antenna 10. It should be noted that although Figure 11A is shown with a circle for simple description, but the power r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com