Construction method of cement strength prediction model and cement strength prediction method

A technology of strength prediction and construction method, applied in the field of cement strength prediction, which can solve the problem of low accuracy of cement strength prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

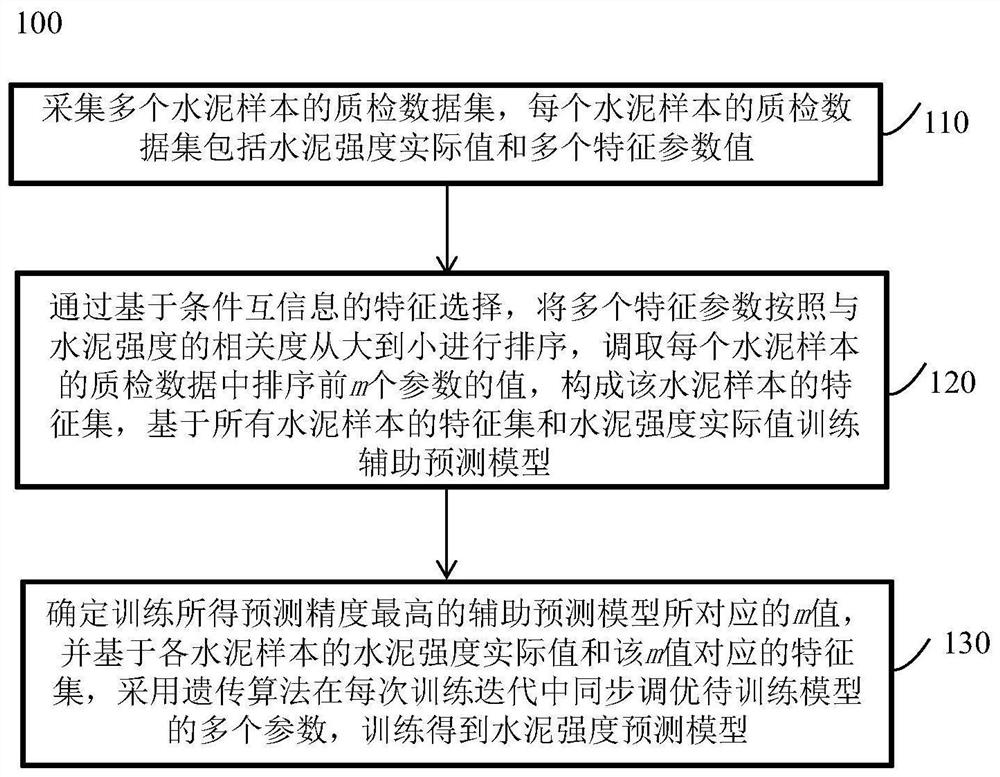

Method used

Image

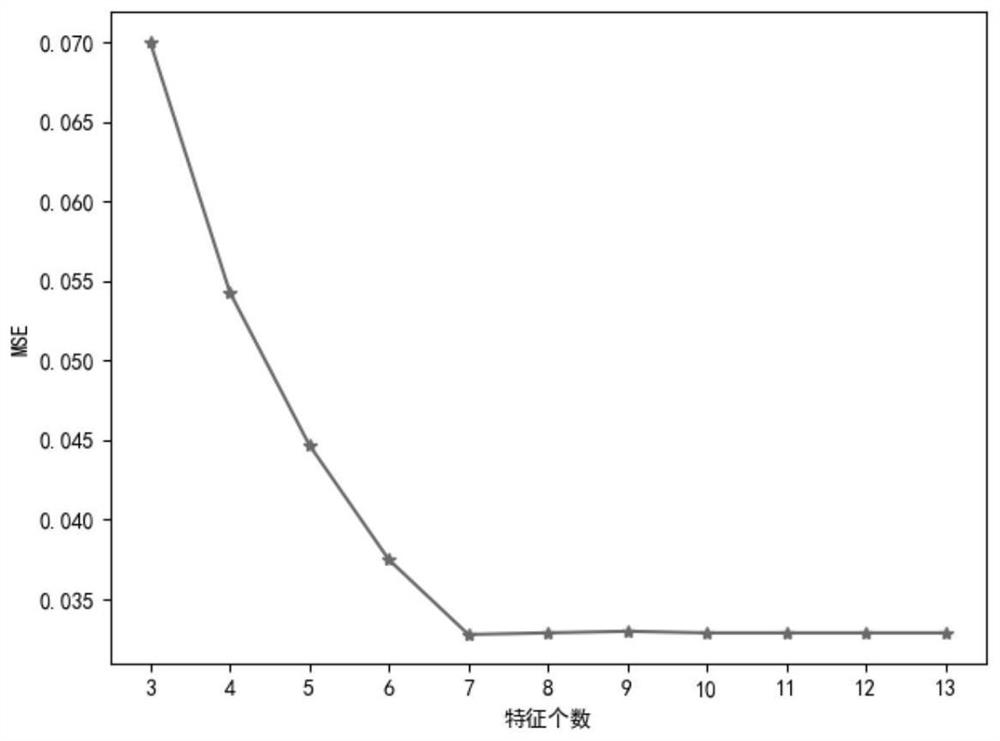

Examples

Embodiment 2

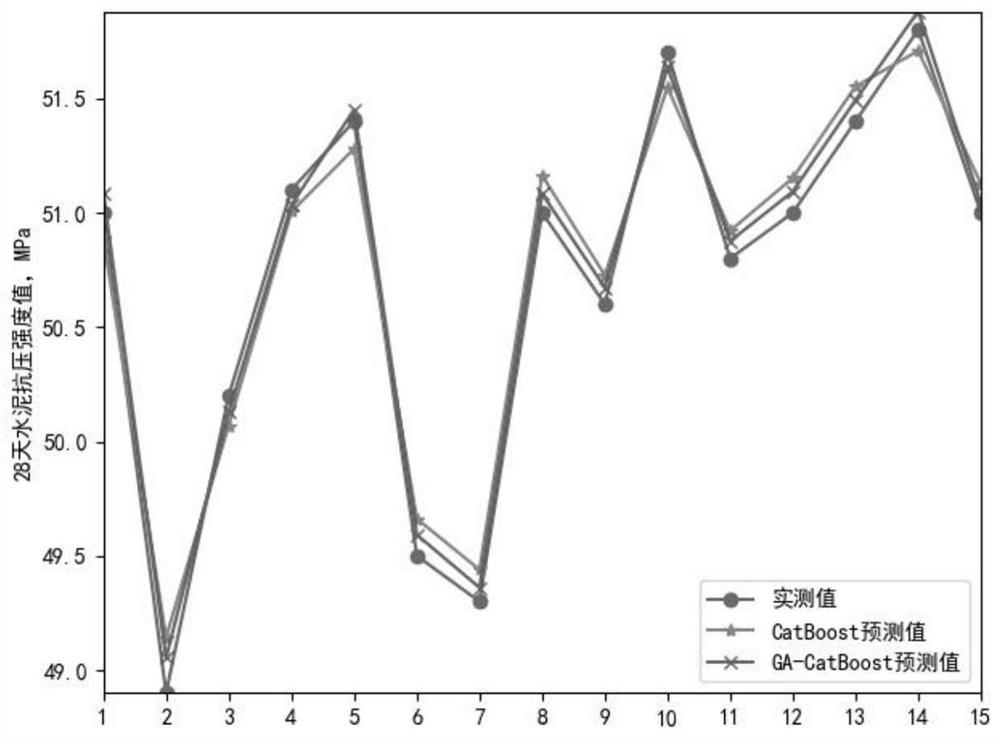

[0084] A cement strength prediction method, comprising: collecting a quality inspection data set of the cement to be predicted, and obtaining m characteristic parameter values in the quality inspection data set to form a prediction characteristic set; wherein the m characteristic parameters are as described in the first embodiment The m characteristic parameters corresponding to the auxiliary prediction model with the highest prediction accuracy; based on the prediction feature set, using the cement strength prediction model constructed by the construction method of a cement strength prediction model as described in the first embodiment above, to predict the to-be Predict the cement strength of cement.

[0085] Cement strength generally can be verified by 28 days or longer, and the cycle is longer. The present invention adopts the cement strength prediction model constructed by the construction method of the cement strength prediction model as described above to improve the a...

Embodiment 3

[0087] A computer storage medium, the machine-readable storage medium stores machine-executable instructions, and when the machine-executable instructions are called and executed by a processor, the machine-executable instructions cause the processor to implement the above embodiments A method for constructing a cement strength prediction model described in one and / or a cement strength prediction method as described in the second embodiment above. The relevant technical solutions are the same as those in Embodiment 1 and Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com